The terms Rat and Mouse have been used by enthusiasts to refer to Chevy's big- and small-block engines for decades. But, there is growing use of GM's LS engine family in the rodding world, and that brings with it a conundrum: What's the appropriate rodent reference?

As we'll illustrate in this story, the LS engine is capable of producing big-block-style displacement and power in a small-block-sized package. It seems like something larger than a mouse yet smaller than a rat fits the bill, so how about "squirrel" or "marmot"? Nah, doesn't fit. "Nutria?" No, that's no good, either.

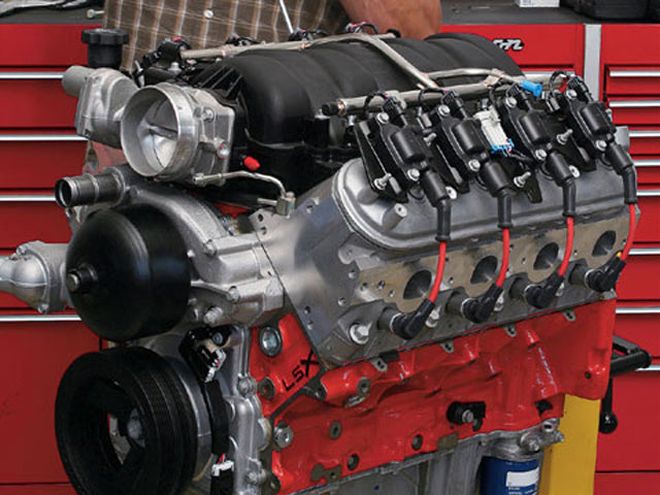

Nickname notwithstanding, the LS platform has much to offer for street rod builders. It's a compact, minimalist design that is relatively easy to package, and, with the variety of factory-style aluminum heads, composite intakes, and the like, it's not an anchor over the front wheels, either. Oh, and it has tremendous performance potential.

Last year, General Motors' Performance Parts introduced the LSX cylinder block, which offered a cake-and-eat-it-too proposition-entry-level pricing with competition-level durability. Pro Stock drag racing legend Warren Johnson had a hand in its design, which is targeted at supporting as much as 2,000 hp and very high boost in racing applications. So, a 500hp street engine ought to be a cinch, right?

That's what we hoped to prove with this story. We turned to the LS experts at Thomson Automotive, near Detroit in Redford, Michigan, and GM Performance Parts (GMPP), who were all too eager to participate in a buildup with the new LSX block. Truth be known, GMPP has turned to Thomson Automotive on occasion to help with development work on high-performance and racing variants of the LS engine family, and Performance Parts sent its own Thomas Bates to help with the buildup. We were in good hands with the project.

LSX FoundationThe LSX cylinder block's sub-$2,000 retail price makes it a very affordable foundation for a high-performance engine, and the LSX is made of cast iron rather than aluminum, unlike many other LS production cylinder blocks. Sure, that's inherently heavier than aluminum, but that shouldn't be of great concern, as other components, such as the heads and intake manifold, are lightweight aluminum parts, themselves. Bonus points for the iron casting include exceptional strength and affordability.

Our project engine combined the LSX block-machined to 427 ci-and a raft of LS7 parts from the GMPP catalog. Indeed, almost every component used on our project engine is available from GMPP or GM Parts, including the racing-derived, high-flow aluminum heads, intake manifold, camshaft, and more. The 427-inch displacement enabled the use of GM's newly available LS7 controller, which allowed the engine to start up on the dyno with no separate tuning. The controller was simply plugged into the engine's wiring harness, and the engine was idling smoothly from the first push of the starter button.

While we were hoping for a nice, round 500hp result, the engine combination produced 550 hp and 511 lb-ft of torque on Thomson's engine dyno. This engine combination responds well and is easily converted to carburetion (see sidebar for more information). Most surprising, however, was the ease at which the engine got up and running. By using the GMPP controller, which was pre-programmed with the maps to sustain the 427-inch engine, there was little to do between start-up and the dyno pulls besides let the engine oil come up to temperature, and no timing adjustments, fuel adjustments, or other tuning were required. It was almost too easy.

Driveability with the production-style EFI system is as smooth and linear as you'd expect from a combination using mostly regular-production components. The idle quality and throttle response are excellent thanks to the LS7 controller, and there are no "dead" spots in the power curve, either; the engine simply keeps building power past 6,000 rpm.

Installation And Transmission ConsiderationsWith 550 hp on tap and the torque output of a healthy big-block from the bygone musclecar days, there are numerous implications for installing this engine in a street rod, be it a lightweight, fenderless Deuce or a full-fendered sedan from the late 1940s.

Fitting the relatively compact engine on a chassis isn't so hard, but some adaptation will be required to use an electronic throttle. The alternative is replacing the electronic version with a conventional, cable-operated throttle.

Also, it will be necessary to beef up the drivetrain in order to efficiently absorb all that torque, so that means backing the engine with a stout transmission. A properly built Turbo 400 will do the trick, but we like the idea of GM's late-model 4L60 and 4L80 electronically controlled overdrive transmissions. The 4L80 is the reincarnation of the original Turbo 400, while the 4L60 is based on the lighter-duty 700-R4.

The advantages of the late-model transmissions include the fuel economy benefits of an overdrive gear and the modulated performance of electronically controlled torque converter lockup. Like the engine, these transmissions require a controller, and, as luck would have it, they're also available from GM Performance Parts. An adapter will be needed to convert the transmission's electronic signal to be used by a mechanical speedometer, and TCI Automotive and other aftermarket manufacturers offer such speedo control units.

The engine's fuel-injected driveability and the overdrive transmission's economy make for a great long-haul, worry-free combination. There are no timing or carb-jetting adjustments to worry about, especially on long tours and varied altitudes, so the crispness of the performance is outstanding.

Ballpark Cost If you're wondering about a ballpark price for duplicating this LSX engine, it is roughly $12,000 in the form you see on our pages. And, unless you have a machine shop in your backyard, you'll need to tack on a few hundred bucks for the finish work on the block, since GMPP delivers the LSX block rough-bored.

We'd likely spend a few more bucks dressing up the engine, compared to the as-built condition seen in this story. First, we'd find some snazzier valve covers and a coil pack relocation kit. The valve covers are available from a variety of manufacturers, but we're keen on MSD's coil-relocation brackets, which move the coils to the rear of the engine for a more traditional look. We've also seen the plastic, factory intake manifold painted, and that would be next on our to-do list; painting it to match the car's body color or the same Chevy Orange as the cylinder block are a couple of easy ideas.

Personalization and dress-up costs notwithstanding, the word "value" is not out of place when describing it-especially when considering its performance. And, speaking of descriptions, we've gotten to the end of the story without a suitable rodent reference. Chipmunk? Guinea Pig? No ... too cute. We can't envision a dark shades-wearing rodder rumbling up at cruise night and answering, "It's a blown, alcohol-swilling Hamster motor" when asked what's under the hood.

Maybe we should just call it the LSX and leave it at that.

Dyno DetailsHere are the results of the LSX 427 engine on the SuperFlow dynamometer (STP correction) performed at Thomson Automotive. Peak numbers are in bold.

Converting To CarburetionOur project engine used the fuel-injection setup from the LS7 engine, but it is very easy to build the engine with a carburetor. This allows for a more traditional underhood appearance, while also easing the installation procedure in a street rod. This is because a traditional throttle cable and accelerator pedal can be used, and no provisions for the LS7's high-pressure fuel system are required-although a remote-mounted fuel pump is needed, as there is no provision for a block-mounted pump.

Intake manifolds to fit the different styles of LS cylinder heads, round port and rectangular port, are readily available in the aftermarket and from GM Performance Parts. In fact, GMPP offers intakes for the LS7 heads in both a conventional single-plane style and a version with cast-in bosses for throttle-body-type EFI or nitrous.

In addition to the intake and carb, converting an LS engine to carburetion also requires an ignition control box, because there is no distributor used with the engine. The good thing about that is timing is instantly set when the engine is turned on once the ignition coils are mated with the spark box, so your timing light is not needed.

The final consideration for carbing an LS engine is performance. Careful tuning with the correctly selected intake and carb can return greater horsepower than a comparable fuel-injection system.