Despite the fact that the 350 Pontiac engine generally garners little attention in the hobby, HPP still receives a fair amount of questions regarding building them up. Some owners want to retain numbers-matching block status and add some tire-smoking power, and others desire to be different and not simply perform a traditional 400 or 455 swap in an effort to increase performance.

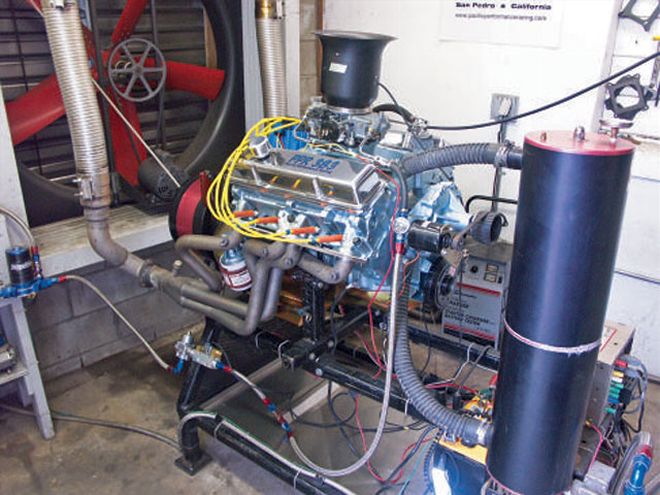

For those who fit into either category, Ken "Ace" Brewer from Pacific Performance Racing (PPR) has an answer. PPR, home of Tomahawk Performance Products, has just released a brand new 4.00-inch stroker package for the plentiful and very-inexpensive-to-buy 350 engine that transforms it into a 383-cube thumper. Follow the recipe outlined here, and you can look forward to 462 horsepower at 6,100-rpm and 436 lb-ft of torque at 4,400 rpm. The beautiful part is that the combination employs a lightweight reciprocating assembly for a quicker rate of rev, a 9.6:1 compression ratio for pump gas, valve sizes that quiet the old complaint of too much shrouding in the small bores, and it's affordable. How affordable? Does $1,595.95 (under $1,400 with 5140 rods) for a complete balanced Ultra Lite rotating assembly with forged pistons and forged steel rods ring your bell?

Some of you may be asking, why not just build a 400? That's a reasonable question, assuming you have one at the ready. But the fact that few Pontiac hobbyists seem to want 350s makes cores very cheap, if not free, and the 350/383 could be considered the underdog in any race against a larger engine from any camp, so there is the spoiler factor as well. If nothing else, Pontiac fans have a new number to play with.

Think how much fun it will be upstaging the Bowtie and Mopar brigades, who owned exclusive 383 bragging rights...until now. Remember, this thing actually cranks out some power. If it didn't, we wouldn't waste time telling you about it. Now go pull a 350 out of the scrap bin and get started!

HPP ENGINE BUILDUP WORKSHEET Engine Displacement383 Horsepower462 Torque436 lb-ft Bore/Stroke3.905/4.00 Block/Crank Combo350 Block/428 crank Bore/Stroke Ratio0.976:1 Rod/Stroke Ratio1.7:1

Bottom End Block '73 350 2-bolt main Preparation Bottom fill with block filler, thermal clean, bore and hone with torque plate, line hone mains with studs, surface to zero deck Deck Height 10.16-in Crank 428 Tomahawk Performance Products crankshaft, 3.00-in mains and BBC 2.200 rod journals Preparation Rifle brush and clean Balancer Professional Products Powerforce Elastamer Rods 6.800-in, Tomahawk Performance Products Ultra-Lites, 756g Bearings King HP series rod bearings std, King AM series main bearings std Pistons Forged, Probe/PPR Piston-to-deck Height Zero Piston Pins 0.990-in, Probe, tool steel Method Used to Retain Piston Pins in Pistons Double Spiro-locks Rings 1/16, 1/16, 3/16 Total Seal, plasma moly Preparation File fit

Balancing TypeNo hole balance for less windage Specs: Piston and Pin539.5g Piston Rings48.4g Pin Locks4.7g Total Rod756g Rotating Rod524.5g Bearing50.6g Bobweight1,979.3g Oiling System Windage TrayTomahawk Performance Products, 3/4 stock type Crank ScraperIshihara-Johnson, Zero-Tolerance Teflon, dual sides Oil PanMilodon, Road Race, four trap doors Oil Pump10540 Melling Select High Performance, 60 psi, 3/4 pickup PreparationInspect prelube

Heads Casting Number#16 small valve ChambersOpen Head ModsCNC-Ported at SD Performance Combustion Chamber Volume77 ccs Compression Ratio9.6:1 ValvesFerrea 2.08/1.71-in Angles Used in Valve JobIntake: top-30-deg, seat-45-deg, bottom-70-deg;

Exhaust: top-30-deg, seat-45-deg, bottom-75-deg ModsCNC-Porting RetainersManley KeepersComp Cams Valve GuidesBronze liners Valve SealsViton Rubber Rocker ArmsTomahawk Performance Products Rocker Shafts System, 1.6:1 roller PushrodsPRW chrome moly Diameter5/16-in Length8.800-in Head BoltsARP

Cam Brand Crower hyd. roller Duration at 0.050 234/242-deg Lift 0.549/0.573 Lobe Separation Angle 112-deg Installed Position 108-deg Lifters Crower hyd roller Valve Springs Crower double Seat Pressure 130 lbs Open Pressure 330 lbs Timing Chain S/A 9 Keyway true roller with removable bronze bushing

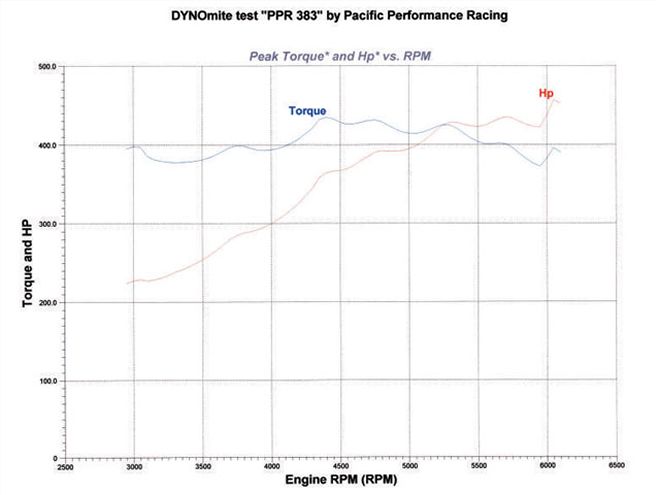

Mounted on the PPR 1,500 horsepower Dynomite dual rotor dynamometer and exhaling through a set of Doug's D564 '64-'67 GTO headers, over 20 pulls were made on the fresh 383. Peak readings were 462.6 horsepower at 6,090 rpm with 436.2 lb-ft at 4,389 rpm. All of this was on 91-octane pump gas with the ignition timing set at 34 degrees.

Mounted on the PPR 1,500 horsepower Dynomite dual rotor dynamometer and exhaling through a set of Doug's D564 '64-'67 GTO headers, over 20 pulls were made on the fresh 383. Peak readings were 462.6 horsepower at 6,090 rpm with 436.2 lb-ft at 4,389 rpm. All of this was on 91-octane pump gas with the ignition timing set at 34 degrees.

Induction CarbHolley Street Avenger, 770 cfm, vac sec, Jets#71/#75 Fuel PumpDyno Pump/Magna Flow 500 gph Fuel RegulatorAeroMotive High Flow Fuel Lines1/2 and 3/8 Intake ManifoldTomahawk Performance Products, single-plane ModsNone Ignition DistributorWAPP HEI WiresDyno/ACCEL Graphite for no computer interference Total Timing34-deg Initial Advance13-deg

Exhaust HeadersDoug's Primary Tube Diameter1.75-in Collector Size3.00-in

Cylinder Head FlowLiftIntake CFMExhaust CFM0.{{{100}}}71.759.10.200143.8107.80.{{{300}}}197.2147.10.400233.6174.90.500248.4197.70.550255.7--0.{{{600}}}--212.7

Cylinder Head FlowLiftIntake CFMExhaust CFM0.{{{100}}}71.759.10.200143.8107.80.{{{300}}}197.2147.10.400233.6174.90.500248.4197.70.550255.7--0.{{{600}}}--212.7