Last month HOT ROD, in conjunction with Duttweiler Engineering, began evaluating the performance potential of the widely available 6.0L LS-series truck engine. We were able to raise output from the stock observed baseline of 355 hp and 396 lb-ft of torque to about 426 hp and 442 lb-ft with basic bolt-ons-Dynatech headers and cats, a FAST intake manifold and 90mm throttle body, and Crane's 1.8:1 adjustable rocker-arm conversion kit-plus recalibrating the stock ECU using HP Tuners' VCM Suite, unique Windows-compatible software that permits hacking any table in the stock computer. Throughout this entire first phase, the heads and cam remained stock.

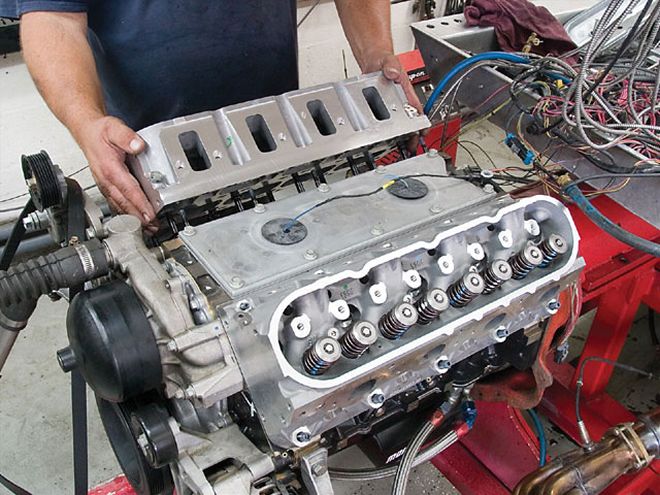

We remedied that this month. Engine tech Ed Taylor bolted on GM's new L92 cylinder heads and then shoved cam after cam into the motor. If that weren't enough, we finished off with an old-school single-plane intake and carburetor to see how a late-model engine runs with a "crude" fuel-metering system. Phase 2 ended with 535 hp and 452 lb-ft of torque, although with the carb and larger cam the engine's mild street manners were starting to go away.

But let's not get ahead of ourselves. Follow along on our LS path to power as tried-and-true hot rod tricks yield big torque and power gains.

LS-series engines have traditionally used a cathedral-style intake port (top). The L92 heads have big rectangular intake ports (bottom) that are based on the ports originally developed for the C5R and LS7 heads. However, the port spacing is unique to the L92.

LS-series engines have traditionally used a cathedral-style intake port (top). The L92 heads have big rectangular intake ports (bottom) that are based on the ports originally developed for the C5R and LS7 heads. However, the port spacing is unique to the L92.

L92 Head Swap

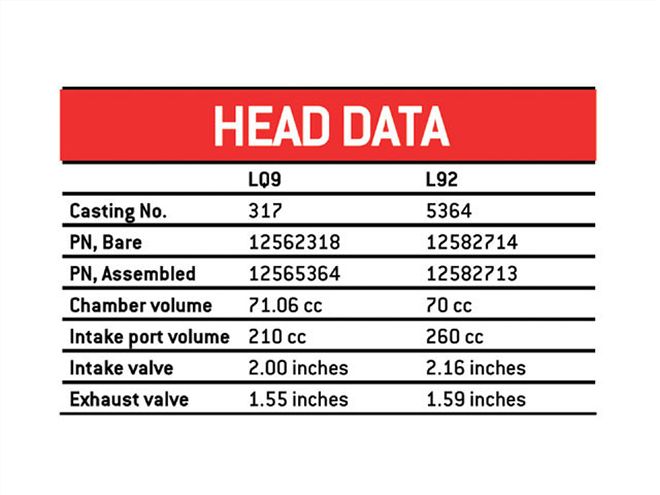

The new L92 6.2L VVT (variable valve-timing) '07 Cadillac Escalade and GMC Yukon Denali feature significantly upgraded cylinder heads with Rat motor-sized rectangular intake ports. Available to hot rodders at a very attractive price through GM Performance Parts' program, L92 heads bolt onto earlier LS-series engines with 4-inch (or larger) bores. But as of this writing (July '07), there was still a major downside: No L92-compatible aftermarket adjustable rocker arms or EFI-style intakes were available. FAST is said to be working on a version of its intake that fits, and surely it won't be long before adjustable rockers appear.

In the meantime we made do with stock nonadjustable 1.7:1-ratio rocker arms, then installed GM's Australian Holden car-style intake with a FAST 90mm throttle body. For the initial runs with the new heads, Phase 1's stock LQ9 cam, Moroso oil pan, and Dynatech headers and cats were retained. Running on 91-octane pump gas, the L92 heads needed only 23-24 degrees of lead, 2 degrees less than the LQ9 heads liked. With the new heads the engine peaked at 425 hp and 443 lb-ft, within two numbers of the previous Phase 1 output. Average output was virtually a wash, too.

But remember: In Phase 1, the engine had the advantage of the superior FAST intake plus Crane 1.8:1 arms that increased the stock cam's valve lift about 0.027 inch. Scratch these parts and the engine only makes 408 hp and 433 lb-ft with the stock long-runner truck intake, a smaller, 75mm throttle body, Dynatech headers, stock nonadjustable 1.7:1 rockers, and an ECU tune-up. So once you take the better rockers and intake off the table, the L92 heads/L76 intake/90mm throttle body combo is worth about 18 hp and 9 lb-ft at the peak, trading off only a few numbers below 2,700 for midrange and top-end gains.

Scoggin-Dickey sells fully assembled L92 heads for around $400 each. A pair of assembled L92 heads, the L76 intake and DBW throttle body, Fel-Pro head gaskets, new rocker stands, and stock L92 offset intake rockers can be put together for $1,835. That's around $290 less than what you'd have to shell out for the Crane adjustable rocker kit, FAST intake, and 90mm cable-driven throttle body needed to make about the same numbers with the LQ9 heads.

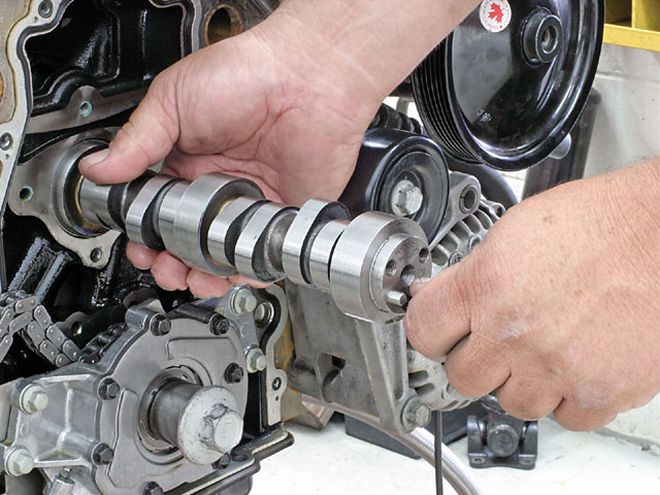

Cam Flog

The L92 heads ran well even with the stock cam, but taking advantage of their superior top-end flow requires a cam change. Larger cams require stouter valvesprings than those installed on GM's complete head assembly. If you intend to change the springs, retainers, and valve locks, you can save over $170 by purchasing the heads bare and piecing them together from individual parts.

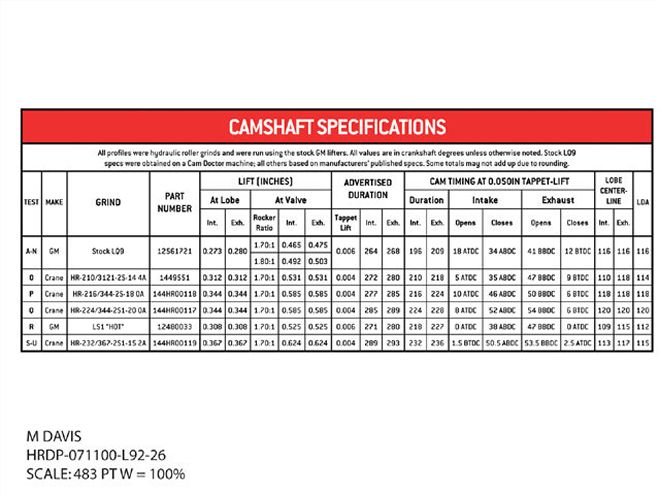

Duttweiler ran five test cams through the motor. All had wider LSAs than we're used to seeing on old-school Chevy small-blocks. Fuel-injected LS engines generally like wide cam-lobe separations (also known as LSA, or lobe separation angle), which tend to generate a calm idle for good driveability, reduce overlap for lesser emissions, and generally interface well with all of today's myriad power accessories. A wide LSA also closes the intake valve later so it builds less cylinder pressure down low, which helps fight detonation tendencies on current-production LS engines that run over 10.0:1 stock compression ratios on pump gas. Yet another factor is that on cams with otherwise equal duration, a wider LSA offers more piston-to-valve clearance. That's important since the stock flat-top pistons lack valve reliefs.

Crane's PN 1449551 hydraulic roller cam was the torque champion and is our pick for a daily driv-er. If top-end power is the be-all-end-all, use the peaky Crane PN 144HR00119.

Crane's PN 1449551 hydraulic roller cam was the torque champion and is our pick for a daily driv-er. If top-end power is the be-all-end-all, use the peaky Crane PN 144HR00119.

The LSAs on the four Crane test cams ranged from 114 to 120 degrees (see cam specs table). Also tested was the GM Hot cam, which had a 112-degree LSA and a lopey idle. It turned out that the first step up from stock-Crane's PN 1449551 with 210/218-degree duration at 0.050-inch tappet lift-was a real torque monster, churning out more peak and average lb-ft than any other cam tested. Compared to the stock LQ9 cam, it gained 20 lb-ft at the peak to pound out 463 lb-ft, averaging 420 lb-ft overall. Its 462 hp represents a 37hp increase over the stock cam, and it also averaged the most power of any cam tested from 3,700 to 5,900 rpm. It idled at 21 inches of vacuum and outperformed the LQ9 cam at every rpm point.

The other cams got progressively more radical, trading off low- and midrange torque production for top-end power. GM's Hot cam had one area in the midrange with a pretty good power bulge. The most radical cam-Crane's 144HR00119-made the most power, cranking out a whopping 510 hp using EFI. However, it was down in torque and power output below 4,800 rpm and 5,300 rpm respectively. It idled at 15.5 inches, about the minimum needed to keep the computer happy.

Test Description

Letters below correspond to the test designators in the adjacent tables and graphs. Test designation sequence continues from the Phase 1 LQ9 tests (Oct. '07).

Carb Versus EFI

The only other intake available for the L92 heads is GMPP's 4150 flanged carburetor intake. Dutt- weiler bolted the single-plane high-rise configuration onto the motor, topped by the shop's 750-cfm carb. The biggest cam tested with the EFI intake (Crane's 144HR00119) was retained. Coincidentally, at this time one of the high-flow catalytic converters went south. They were removed from here on out. Previous testing showed that the cats had little effect on the engine's overall power curve.

Without a spacer, the carb setup made 449 lb-ft at 5,500 rpm and 535 hp at 6,900. Adding a Wilson spacer boosted output to 452 lb-ft and 539 hp, the latter peak occurring 200 rpm lower. The most power seen so far was 539 hp, but torque-even compared to the same cam with EFI-was down. On the dyno the engine was not happy under 2,000 rpm and, in fact, only really came into its own over 5,000 rpm. A combo like this-although not fun for a daily driver-would do well at the drags if the car were properly geared.

The short-runner intake really helps the engine breathe on the top end, but it took 10 degrees' more ignition advance to make the best numbers with the carb than it did with EFI. The engine was able to take more lead without getting into detonation because it made less torque at the low rpm, where cylinder pressure is highest and detonation is most likely to occur.

These numbers were made with wide-LSA cams basically optimized for EFI applications. Narrowing the LSA (increasing the overlap) can help pull more fuel through a carburetor. With a cam ground on, say, a 110-degree LSA, the carb should pick up a little more in the low and midrange. And what if we drilled the blank bosses on the carb intake to run port EFI? Then there are some new trick Magnuson blowers we gotta try. Sounds like a plan for next month. Stay tuned.