Don't think a diesel can make horsepower? Gale Banks' Duramax makes 650 or it.

Don't think a diesel can make horsepower? Gale Banks' Duramax makes 650 or it.

For most hot rodders, diesel performance usually means giving a truck more pulling power to get over a hill with a car trailer in tow. But a diesel engine on the race track? We're talking sled pulls, right? No, and we know one guy who can show you otherwise. Gale Banks has the chops from either side of the fuel pump, having made a name for himself with both gas and diesel performance products. His company, Banks Power, has built everything from gasoline-fueled, twin-turbo, small-block Chevys to high-powered all-terrain, diesel 4x4s (which rumbled through the Hot Rod Power Tour(tm) in 2005). So who better than Banks to combine the best of both worlds? Imagine crossbreeding a Clydesdale with a thoroughbred racehorse, and you get the idea. The result is a horse of a different color, one with stump-pulling torque and a fast gallop to boot.

"I'm taking all of my years of gasoline performance and applying [them] to a diesel engine to make it more gas-like," Banks explains. "We got rid of some of that diesel torque and lost some of the weight because we like it to spin faster."

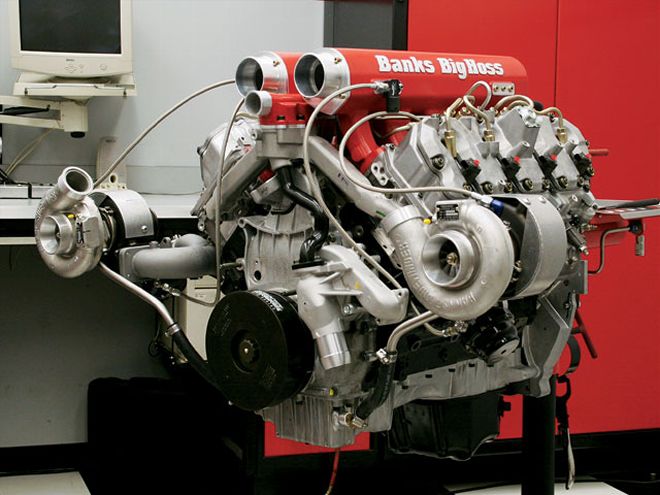

The result is a new type of engine called the Sidewinder D-Max Type-R being showcased in a heavily modified GMC Sierra (see sidebar on page 136). This diesel mill pounds out 800 lb-ft of torque throughout 3,000 to 4,500 rpm in a pancake-flat power curve. Of course, big torque is no surprise for a diesel, and comparatively smaller horsepower numbers are the norm. But this engine also cranks out 650 hp at 4,300 rpm, an unheard of powerband for a diesel. And Banks' goal is to redline at more than 5,000 rpm.

To shed pounds and decrease rotational resistance for higher revs, Banks reshaped the crankshaft's counterweights into an aero-wing form with a blunt leading surface that tapers quickly to a thin trailing edge. This configuration sheds oil better than the more gradual "knife-edging," which can allow the oil to adhere longer. Even though the reciprocating mass weighs less than stock, the overall weight of the Banks engine is about the same as a stock one due to the addition of an extra turbo. It weighs about as much as an all-iron big-block Chevy.

To shed pounds and decrease rotational resistance for higher revs, Banks reshaped the crankshaft's counterweights into an aero-wing form with a blunt leading surface that tapers quickly to a thin trailing edge. This configuration sheds oil better than the more gradual "knife-edging," which can allow the oil to adhere longer. Even though the reciprocating mass weighs less than stock, the overall weight of the Banks engine is about the same as a stock one due to the addition of an extra turbo. It weighs about as much as an all-iron big-block Chevy.

For gasoline guys unfamiliar with diesel numbers, that's more than double the usual horsepower. According to Banks, a stock LLY block of a GM 6.6L Duramax with a manual transmission typically maxes out at 310 hp at 3,000 rpm and 605 lb-ft at 1,600 rpm. Those numbers are fine for hauling a load, but pretty ho hum for any sort of hot rod, especially when you factor in the heft of a diesel block. Diesels require very rugged parts to withstand high cylinder pressures, and such heavy-duty parts typically limit a Duramax engine to a redline of 3,200 rpm. Now imagine revving it up to as much as 5,000 rpm, nearly 2,000 rpm above redline. Depending on the tuning, Banks can alter the output from 650-700 hp and 800-900 lb-ft of torque. Note that while the torque can increase as much as 50 percent, the horsepower more than doubles. More torque could be dialed in, but the Banks team intentionally limits it to make sure the rest of the drivetrain will survive the onslaught of power.

Before we get into how Banks did it, a simple question arises: Why bother? Well, anybody who's filled up his tank recently knows we're in the middle of a sea of change with regard to fuel, and somebody needs to rock the boat. "Diesel is already an alternative fuel," Banks points out with disarming simplicity. "Basically, I want enthusiasm for diesel. My feeling about [the potential for] diesel is higher speed and lower torque-and future fuel." And that's coming from a guy who cut his teeth building high-performance gasoline engines but later converted to oil burners. The reasons are many for his preference for diesel over gas, and they include its significantly higher energy content per pound. He also points to the fact that since there's no octane limit on diesel, you can't detonate it.

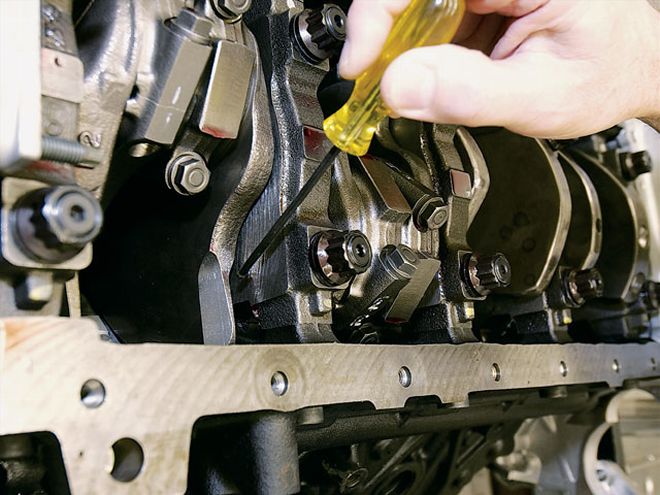

Today, Banks Power is well respected in the diesel community for its range of performance products for all domestic makes of diesels, but Banks chose the Duramax in particular for its design features and durability. "It's elegant-reminds me of a Chrysler Hemi," he says, commenting on the valvetrain and its massive lifters and roller tappets. "The durability of this thing is unbelievable. We've tuned it to death and haven't hurt it."

What did Banks' engineers have to go through to get such a sturdy draft horse to stampede like Seabiscuit? A lot. "All current diesels make torque over horsepower at a 2:1 ratio, and gas engines have a 1:1 ratio of torque to horsepower," he explains. "My goal is to make a diesel that has a 1.5:1 ratio of torque to horsepower. The main thing is to maintain the torque advantage but get rid of the current weight."

Putting a Duramax on a diet required a number of changes-some obvious and others subtle. Starting from the bottom, to reduce the heft of the rotating mass and its resistance, the crankshaft was lightened, knife-edged, and contoured. The weights were given an aero-wing shape with a blunt leading edge that tapers at the tail end.

Here is the difference in size of a connecting rod Banks uses for a high-performance Chevy small-block (right) and a Duramax diesel (left). Borrowing from his experience with gasoline engines, Banks replaced the stock rods on the Duramax with 4340 billet-steel H-beam connecting rods, both polished and shot-peened.

Here is the difference in size of a connecting rod Banks uses for a high-performance Chevy small-block (right) and a Duramax diesel (left). Borrowing from his experience with gasoline engines, Banks replaced the stock rods on the Duramax with 4340 billet-steel H-beam connecting rods, both polished and shot-peened.

If you're wondering if this weight-reduction program might result in a loss of durability, Banks points out that the life span of light-duty diesels is far beyond the projected life of gas engines, with duty cycles measured in several hundreds of thousand of miles. "The edge of life isn't even in the same state," he says. Nevertheless, to handle the increased stress loads, the crankshaft was shot-peened and stress-relieved in a cryogenic bath at minus 300 degrees F. For additional strength, Banks custom-machined a billet-aluminum, dry-sump oil pan that also serves as a block-reinforcement girdle.

Banks' staff also extensively reworked the Duramax oiling system by creating oil pathways in the blocks where none previously existed to supply full-pressure lubrication to re-engineered roller lifters. Full-pressure lubrication will also generally help the engines withstand the increased loads and rpm to which they will be subjected. A seven-stage, dry-sump oiling system circulates 16 quarts of diesel racing oil in the Duramax. Other internal changes included studding the cylinder heads, honing the torque plate, and replacing the stock connecting rods with 4340 billet-steel H-beam rods, both polished and shot-peened.

With the Sidewinder D-Max motor, getting it to increase the burn rate of the fuel required a number of changes to the top end. In applying their talents to this phase of the project, Banks' engine builders had to keep in mind several fundamental differences between gas and diesel engines. In addition to the 17 percent higher energy content of diesel fuel, diesel engines throttle on fuel rather than air and thus can operate with a much wider range of fuel/air mixtures.

On the stock Duramax, a single turbo feeds both cylinder banks through a central intake manifold. But Banks added a second turbo, one for each cylinder bank, which required dual, high-ram, custom, cast-aluminum intakes. The ram effect on a diesel is different than on a gas engine, though, because a diesel throttles on fuel rather than air and can tolerate a much wider range of air/fuel ratios.

On the stock Duramax, a single turbo feeds both cylinder banks through a central intake manifold. But Banks added a second turbo, one for each cylinder bank, which required dual, high-ram, custom, cast-aluminum intakes. The ram effect on a diesel is different than on a gas engine, though, because a diesel throttles on fuel rather than air and can tolerate a much wider range of air/fuel ratios.

"Everything you think you know about porting a gas engine doesn't necessarily apply to a diesel," explains engine builder Dave Basham. "You can flow more air, but if it doesn't swirl enough, you get black smoke. It's a fine balancing act."

No wonder then that at least four variations of cylinder heads were developed before Banks found the precise combination. Flow testing produced data that helped increase intake-port flow by more than 30 percent at 0.500 lift and exhaust-port flow by a whopping 50 percent at 0.500 lift.

Interestingly, on the fire deck (the term for a diesel's head surface), there's no combustion chamber. Instead, it's located in the piston head to facilitate the swirl mentioned above, which in turn reduces smoke. A special flow bench that measures swirl was used to design the proper shape for the 14.5:1 forged pistons.

Other alterations included custom, stainless steel intakes and larger-diameter Inconel stainless exhaust valves to replace the stock intake and exhaust valves. Both valves are now 33 mm, compared with 31 mm stock. Custom manganese bronze, self-lubricating valveguides and tungsten carbide alloy valve seats are used to conduct as much heat away from the surface of the valves as possible. To reduce valvetrain mass, smaller and lighter lifters were developed to travel in bronze guide bushings pressed into the Duramax blocks. New Banks-spec, custom-ground roller camshafts take advantage of the higher lift capability of the new valvetrain, higher cylinder-head flow, and boost pressure of the race engine. Finally, even the harmonic balancer was replaced with a custom Fluidampr balancer designed especially for this engine.

Banks worked closely with Bosch on the Type-R's engine electronics, and similar technology appears on the Banks Power PDA that controls its diesel-tuner package.

Banks worked closely with Bosch on the Type-R's engine electronics, and similar technology appears on the Banks Power PDA that controls its diesel-tuner package.

A diesel isn't complete without a turbo, and the Type-R Duramax wasn't complete without a pair of extreme turbos. The Garrett ball-bearing turbochargers feature stainless steel turbine housings and magnesium compressor housings, as well as aluminum compressor wheels and nickel-based alloy turbine wheels.

Another advantage of diesel engines over gas is their ability to handle much higher boost levels. In this performance application, the Garretts generate pressure in the neighborhood of 44 psi. Of course, that kind of pressure requires extra sealing of the heads to the block using Garlock Helicoflex low-distortion sealing rings, along with custom studs to replace the stock head bolts. To spin the turbos, Banks fabricated stainless steel tubular headers, and boost is controlled electronically with Banks-designed dual wastegates. Two large air-to-air intercoolers reduce inlet-air temperatures to provide maximum air density.

Just as on a gas engine, more boost requires more fuel, but on this diesel, how it's delivered is just as important as how much is delivered. To tailor the fuel delivery to the needs of the engine, Bosch created a higher-capacity system and matching engine-management package, with custom programming handled by Banks' engineers. Included are special fuel injectors with modified spray angles and flow ratings and a higher-volume fuel pump built to Banks' project specifications. The Bosch fuel-delivery system is capable of providing adequate fuel (at 1,800 BAR) for a turbodiesel engine, producing up to 750 bhp and 950 lb-ft. Clearly, Banks has higher levels in mind and designed an excess of capacity.

Think your race car makes boost? Banks' diesel makes 44 pounds of it. To produce this much pressure, Banks bolted on a pair of Garrett, Le Mans-style, ball-bearing turbochargers with stainless steel turbine housings (left) and magnesium compressor housings (right), as well as aluminum compressor wheels and nickel-based alloy turbine wheels.

Think your race car makes boost? Banks' diesel makes 44 pounds of it. To produce this much pressure, Banks bolted on a pair of Garrett, Le Mans-style, ball-bearing turbochargers with stainless steel turbine housings (left) and magnesium compressor housings (right), as well as aluminum compressor wheels and nickel-based alloy turbine wheels.

Above and beyond the specific parts required, additional challenges included tuning the fuel injection for smokeless performance, which required countless hours of laptop time. The engineers can't just pour buckets of fuel into the cylinders at will and then blow out all kinds of sooty exhaust. On the track, black smoke means a black flag from race officials. "Smoke is the negative legacy of diesel-it's just plain wrong," Banks points out. "It's power you can see but not use."

As for fuel quality, the diesel version of race gas is low sulphur with a higher cetane level in the low 50s. (Standard No. 2 diesel would produce more smoke and less power.) The only spiking done to the Type-R's fuel is with a bit of alcohol, about 5 percent to increase the oxygen content. Banks chose not to mess with propane or nitrous injection as sometimes used by diesel drag racers.

Even with the enforced limit on torque output, the power of this Type-R Duramax is still prodigious, as evidenced during a recent track outing where the rearend suffered some damage. Even though Banks is showcasing the engine in a road-race truck, he envisions initial applications for his high-revving diesel in the marine field and defense projects. But hot rodders are still in for a treat. He's working on a diesel street rod with all-wheel drive. Hey, when you've got big torque and horsepower numbers from the same mill, why not use it to hook up as many tires as possible?

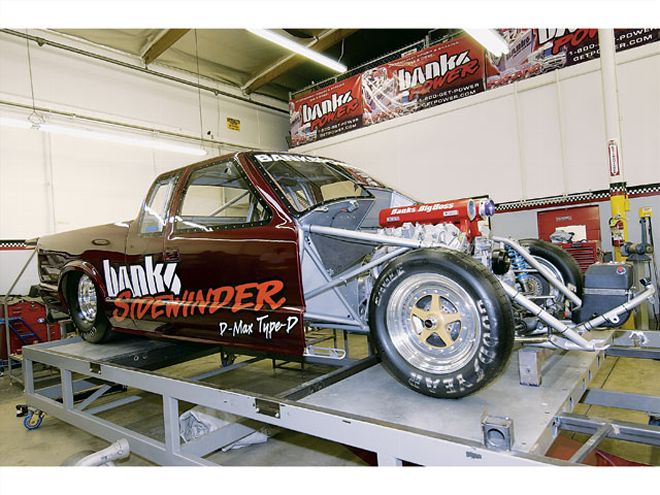

"> Here's an oxymoron: a road-racing, diesel pickup.<BR>

Here's an oxymoron: a road-racing, diesel pickup.<BR>

Sidewinder D-Max Type-R

Gale Banks has a habit of breaking things, like speed records and conventional rules. His world's fastest diesel pickup truck, which set a land-speed record at Bonneville of 220 mph, is just one example. Now he's taking on road-course events in a diesel as well. If you think it's odd for a diesel to compete in an endurance event, look no further than the Audi R10 TDI that recently won the 12-hour race at Sebring.

Getting a truck to run hard and long on a road course requires a massive amount of development to build a NASCAR-style chassis and fabricate aerodynamically enhanced body panels. Starting with the frame, the truck was fabricated from a combination of mild steel and chrome-moly tubing. Rules don't restrict engine placement, so the Duramax was located 18 inches back and 16 inches lower than stock to achieve a 50/50 balance. For improved power/weight ratio and handling agility, the overall weight was kept to 3,200 pounds.

Banks plans to launch a diesel drag truck later this year, with an even higher projected rev limit of 7,000 rpm.

Banks plans to launch a diesel drag truck later this year, with an even higher projected rev limit of 7,000 rpm.

Working in conjunction with crewchief Sheldon Tackett, driver Don Alexander designed the front and rear geometry. Front A-arms and spindles were fabricated at Banks and mounted along with Koni shocks and Eibach springs, which control the rear three-link. Big 13-inch Wilwood brakes put the bite on the Bogart wheels, shod with Goodyear Eagle racing rubber (fronts are 25.5x12-17 and the rears are 28.5x14.5-17).

With tons of torque on tap, Banks chose to experiment with a four-disc carbon/carbon clutch assembly in a Tilton magnesium bellhousing. The rest of the driveline is equally stout. The gearbox is a four-speed clutchless unit linked to a Speedway Engineering Track-Nine 9-inch Ford-style rearend with a Detroit limited-slip diff and a three-link layout.

As for the body panels, although loosely based on the GMC Sierra, they were heavily massaged and remade in composite material by Banks' stylist Sean Torres, all with an eye to less wind resistance and improved performance. The latter aspect required designing special vents and ducting to ram air to the turbos and for engine and brake cooling, along with shrouding around the tires and rocker panels to take advantage of ground effects. The Type-R was also outfitted with a rear pan to better manage airflow exiting under the rear of the truck.