Horsepower is at the heart of Vette and other enthusiast publications. It’s thrilling to read about Corvettes with 650 hp, 850 hp and even more. Unless the numbers are speculation, they come from dynamometers (dynos). With so many articles about wild engine builds, it may seem that dynos are the exclusive domain of highly modified engines. The truth is that dynos are equally valuable for mild mods and even purely stock engines. Here, we’ll explore the costs and benefits for dyno tuning relatively stock Corvettes.

Why take a stock Corvette to a dyno for tuning? The factory chooses settings for air/fuel ratio (AFR), timing and other parameters so that the car’s performance is “good” in a wide range of circumstances: altitudes from sea level to 10,00 feet, temperatures from 40 to 130 F, gas from 85 to 103 octane and engines in various stages of wear and maintenance. Plus, every car is a little different; injectors and other parts are never exactly identical.

A properly executed tune on a dyno will tailor the settings to the actual condition of your car. Then it will run better than just “good,” it will run at its optimum. And the benefit is not only peak horsepower. Power and torque throughout the range can increase to make the car feel better in everyday driving. How long does it take to get these results? Bob Morreale, president of The Tuning School, says that its dyno tuning of a stock late-model vehicle takes about an hour.

And you may just get better fuel mileage—if you can keep your foot off the pedal. A number of fleet managers have taken the tuning course at The Tuning School to be able to retune their vehicles from factory specifications for just this reason. A few more miles per gallon can make many thousands of dollars in savings for a fleet of vehicles.

Selecting a dyno facility

For just a bit of background, dynos measure torque and rpm. With these two measurements they calculate horsepower. A dyno’s usefulness comes from measuring torque precisely so that the effects from changes in components or tuning are accurately and conveniently determined. Dynos do this much faster, easier and more repeatably than seat-of the pants testing on the road or at a dragstrip.

The type of dyno most Corvette owners will use is a chassis dyno because it measures a vehicle’s horsepower at the rear wheels (rwhp). Torque is measured at rollers that the wheels sit on as the engine is powered through its rpm range. Engine dynos, by comparison, dispense with the car and measure crank horsepower directly at the engine. Therefore, engine dynos give larger horsepower measurements because they avoid the significant horsepower losses from the transmission and differential.

The brand and model of dyno isn’t that important for tuning, although dyno manufacturers might like to think otherwise. Every dyno gives somewhat different measurements. For the purposes of tuning, it doesn’t really matter whether the peak hp reading is 405 or 410. What matters is that the dyno can measure the changes in horsepower precisely and repeatably. You want to know whether that part or tuning change you made helped or hurt.

If you’re just looking for some horsepower numbers for personal interest, comparison with friends or for bragging rights—just go to a facility with a chassis dyno and run the car through the rpm range a few times. The cost can be around $75 for three pulls.

However, if you’re looking for someone to tune your car for optimal performance, it’s worth looking for a facility with people who really enjoy what they’re doing. Tuning is a methodical process that shouldn’t be rushed. As mentioned, even with a very experienced tuner, it can take a full hour or more to find the best combination of throttle position, fuel curve and timing for a stock EFI car.

If the people at the dyno facility are abrupt, don’t want to take time to talk to you, or don’t seem interested in your goals—go somewhere else.

Preparing Your Car

Preparing for a day (or hour) at a dyno is easy but here are some helpful tips. Make sure your rear tires are in good condition. The tires may spin at well over 100 mph on the rollers. Place premium gas in your tank if that’s what you normally use and if you are tuning for maximum horsepower. Don’t arrive with a nearly empty tank or one filled with 87-octane gas.

Your clutch or automatic transmission can’t be slipping. Also, if you just installed a clutch, use it for several hours to seat the friction material. Make sure maintenance parts like spark plugs and air filters are in good condition.

Explain to the technicians what you hope to accomplish. Tell them the maximum rpm you want the engine to go to. For example, I said 5,500 because mine was the original engine and has many, many miles on it. In my case, it turned out that going higher wouldn’t have been worthwhile; power began leveling off at 5,000, probably due to the stock exhaust headers, pipes and mufflers.

Finally, you’ll sign a form stating that it’s not their fault if the engine explodes. Don’t let this bother you. The Tuning School has never had a engine grenade on the dyno. In fact, their previous test mule did over 3,500 pulls on the dyno. And if you need a little more reassurance, the test mule they just bought is a C6 with over 100,000 miles. Furthermore, they increased the horsepower significantly over stock. Even with this extra horsepower and an untouched bottom-end, they expect the C6 will go at least 3,500 pulls, too.

One last tip: if you want to stay for the dyno work, dress for outside weather. Many chassis dynos are located in unheated [or cooled] areas where the garage doors can be left open for exhaust ventilation.

Onto the Dyno

The car is placed onto the dyno, positioned with the drive wheels on the roller and then the chassis is strapped down. A secure tie-down can take 15-25 minutes and shouldn’t be rushed. A large fan is placed in front to increase airflow through the radiator. The engine is working at full throttle and at driveline speeds are over 100 mph. Without the fan, there would be only as much airflow as when you’re stuck in traffic [basically none].

A technician sits in the driver’s seat, starts the car, checks the instruments and then slowly runs the car through the gears into a higher gear. With 3.70 rear gears and nearly stock diameter tires, Fourth gear was selected for my test runs. Early manual transmissions like my C3’s four-speed have 1:1 ratio for the top gear and therefore a little less driveline horsepower loss.

Once the car is in the chosen gear, the technician steps on the gas and runs the engine up to the rev limit you chose. A monitor is within view of the technician so he can focus on the rpm and other parameters. After the maximum rpm is reached, the accelerator pedal is released and a pull is completed.

Each pull takes less than 30 seconds but it seems longer when listening to your engine roar at wide-open throttle (WOT). One pleasant surprise is hearing the sound of your car’s exhaust at full song from outside. But be prepared for one unpleasant surprise: the shock of hearing a very loud whining noise when the throttle is closed and the dyno winds down.

The Tuning Trials

Tuning on a dyno can be done much faster and easier on modern Corvettes than on the first generations. The electronic fuel injection systems installed for the last 35 years permit a technician to change air/fuel mixture, timing and other parameters simply by changing programming in the electronic control module (ECM). However, tuning an old-school (carbureted) car involves physical modifications. With the C3 we chose for the dyno time, like with previous generations, changing timing requires a wrench, and changing air/fuel mixture requires changing parts inside the carburetor.

The C3 test engine is fairly representative of C2s and C3s: a 1973 350ci L82. Although the L82 was the higher horsepower small-block that year, it’s still a smog engine. Compression on this engine was upped a little with milled heads and an overbore. Mild porting of the heads, 2 1/2-inch cast-iron ram manifolds and pipes, and a Comp roller cam help it breathe a tad better than stock.

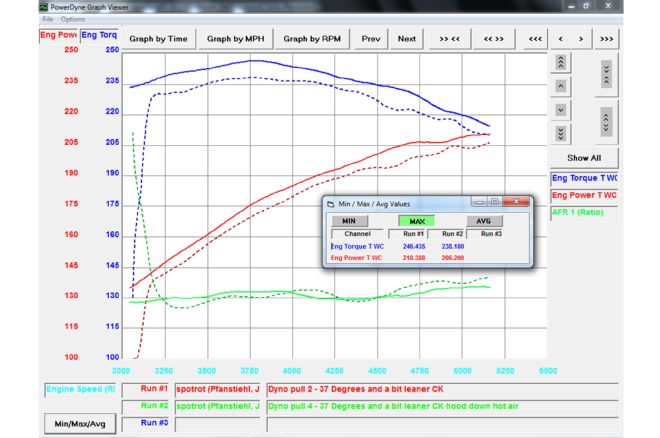

The goal of the tuning was to achieve maximum WOT power. The idle and midrange was already fine for around town. Fortunately, changing this air/fuel mixture on a Quadrajet carb is easy. The Q-jet secondaries are so large in comparison to the primaries, that they are the dominant factor at WOT. Changing the secondary metering rods requires only the removal of the air cleaner lid and one screw. I brought a selection of secondary rods [from Jegs], both leaner (thicker at the tip) and richer (thinner) than the stock rods. With only four pulls we found that slightly leaner rods were optimum.

Although determining the proper ignition timing is critical for modern engines, it’s simpler for older small-block engines. In my experience, around 36 degrees is close enough to optimum. Changing the timing a couple degrees might provide a 1 percent improvement and that would be worthwhile if the car was raced. However, I was more curious about the amount of increase in horsepower with the cold-air induction.

It’s well known that colder (denser) air provides more power. We tried one pull with the hood closed (to use warm engine compartment air), the original factory solid lid on the air cleaner and the hood’s vent blocked off. The second pull was with the hood open (for ambient air) and a K&N filter lid on the air cleaner for increased airflow. The increase in horsepower was clear. [Looking back, I also should have tested with the hood closed and the hood vent open—and that explains why it’s good to plan your tests beforehand.]

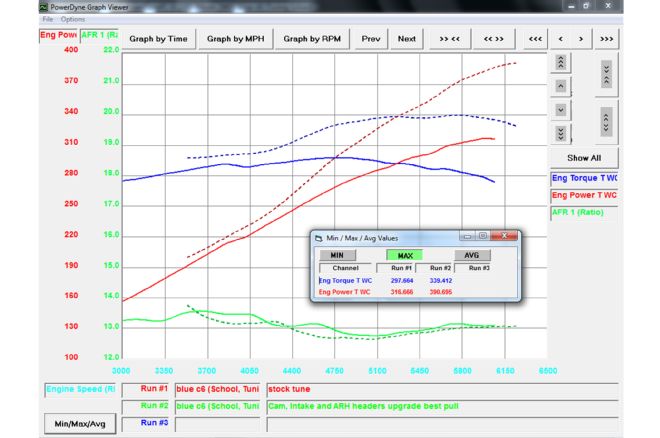

That gives you a taste of dyno tuning for carbureted Corvettes. For owners of late-model Corvettes, let’s look at the effect of dyno tuning with the installation of common performance parts. The Tuning School’s new test mule is a C6. Prior to modifications and tuning, it produced 317 maximum rwhp.

The tuning options via the ECM are much greater on modern Corvettes. Bob Morreale said they are able to control idle, part throttle, and full throttle spark advance and fueling. They are also able to control torque management, which controls how the power is reduced. Power is often applied in a slow manner to avoid shocking the driveline to reduce warranty claims, but the result is an engine that is slow to come up on full power. Power is also reduced on shift points to allow for “smooth” shifts to make some customers happy. By adjusting the torque management, Bob said they are able to gain anywhere from several tenths and a few mph to almost a full second improvement in the quarter-mile. Even stick shift cars have torque management, so there’s always room for improvement. In cars equipped with variable camshaft timing, like the new C7 Corvette, cam timing also can be adjusted within the ECM.

The C6 test mule was beefed up with the addition of a Comp Cams camshaft (248/252 0.615/0.615-inch lift), American Racing 1 7/8-inch headers with catted mid-pipes, FAST 102mm intake manifold and Infinity injectors (72 lb/hr). After engine modifications, The Tuning School recommends not tuning just for WOT because that skips a lot of steps. They started by tuning just the idle. This took about a dozen pulls and changes to optimize idle for the new parts. Then midrange was adjusted until that was optimized. Only then was it tuned for WOT.

Dyno tuning like this takes longer for modified cars than for stock, and can take four hours or more. But the results are worth the time taken with the tuning process. Over 50 rwhp was added to the test mule with no changes to the heads or block. Even more impressive, the torque increased throughout the entire rpm range. That makes for a very strong car on the street. I can personally attest that this dyno-tuned C6 is a thrill to drive. The power it generates when the pedal is down, even at 2,500 to 3,000 rpm, brings your heart rate up and plants a smile on your face.

01. The car is backed onto the Mustang aboveground dyno. Then the lift bed is raised and the car is rolled back until the rear wheels are centered on the dyno’s large roller. One advantage of aboveground chassis dynos is making attachment of the straps easier. The Tuning School uses a model 1750 Mustang dyno, which has very large (50-inch) tire-friendly rollers that can go to 250 mph and provide the inertia-based testing. It is a load-bearing dyno, which better simulates actual street driving.

02. Brett McClelland recommended using four straps to tie down the rear end. It’s also advisable to attach the straps to the Corvette’s frame, not to the leaf spring, at least on C2s and C3s. The differential cover and bolts that attach the spring were not designed to take force in the rearward direction.

03. The front wheels are blocked and then the front end is strapped down to prevent the car from moving sideward. The lower A-arms are solid mounting places for the straps.

04. This is where the rubber meets the roller. The car is pulled down securely onto the large grooved roller to provide sufficient traction. It’s wise to have decent tires—they’ll be going well over 100 mph if a top gear is used.

05. Torque, horsepower and air/fuel ratio are displayed on a nearby monitor. For comparison, the measurements from the current pull are dotted lines while the previous pull is shown as solid lines.

06. After starting the engine and going through the gears up into Fourth, Brett focuses on the monitor as the throttle is opened wide and rpm climbs. The rear wheels are turning at over 120 mph now.

07. The monitor near the driver-side window enables the operator to monitor mph, rpm and AFR. No need to trust this Corvette’s mechanically driven tachometer.

08. Tuning the air/fuel mixture for WOT is easy on a Q-Jet. Just remove one screw and the hanger to change the secondary rods.

09. Over 10 hp in much of the upper range was gained by changing the Q-Jet’s DP secondary rods to CK rods. In a sense, it’s free horsepower because there was no loss of torque in the lower or midrange.

10. Cooler air makes more horsepower. The solid lines show the horsepower and torque developed using cooler outside air with the K&N air cleaner lid. The dotted lines show how power dropped 7-10 hp across the entire range with the warmer engine compartment air (hood down, hood inlet closed).

11. The K&N XStream top filter for the air cleaner lid increases airflow in four ways: more filter surface area, a less restrictive filter element, greater height above the air horn and a straighter path for the airflow from the hood inlet.

12. Search for a dyno facility that enjoys its work. The Tuning School teaches other shops how to use tuning software and dynos to achieve peak performance. They just bought this C6 as a new test mule.

13. Just for fun, they installed a Comp cam, American Racing headers and pipes, a FAST intake manifold and Infinity injectors. That and some methodical tuning on the dyno made this car a serious thrill to drive.

14. Over 50 rwhp was gained after dyno tuning and the change of camshaft, exhaust system, and manifold. Even better, this increase in power was across the entire rpm range. The solid lines show the hp and torque when stock.

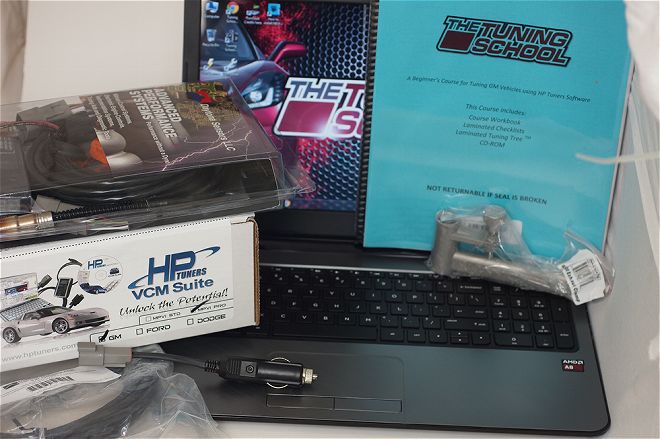

15. The Tuning School has a number of courses for people who want to learn how to effectively tune modern EFI vehicles. This package includes all the hardware and software you need, including a completely set-up laptop.