Car crafters all like to talk about engines. And in our world where there's no replacement for displacement, dropping the "stroker" term into your engine conversation is bound to garner attention. Adding stroke is one of the easiest ways to build displacement, mainly because most production blocks are limited in overbore capacity to 0.030 to perhaps 0.060 inch. But most V-8 production blocks can easily accommodate a minimum of 0.250 inch and often almost 0.500 inch in additional stroke. This does wonders for the displacement curve. Drop a 3.40-inch arm in a 0.030-inch overbored 302 Ford that had a stock 3.00-inch stroke and suddenly you have 347 ci, and you're living large. Even with a conservative 1.2 hp/ci multiplier, you're looking at a 54hp gain just by bumping the stroke. If that's not enough, then chew on this: The dead simplest way to make more torque and bump that acceleration curve is by-you guessed it-increasing displacement.

The only way to increase cubic inches is with a bigger bore, a longer stroke, or both.

The only way to increase cubic inches is with a bigger bore, a longer stroke, or both.

The performance world is full of stroker-crank combinations for almost any engine you can dream up. Better yet, aftermarket iron and aluminum blocks are debuting at an astonishing rate along with matching rotating assemblies. But with all these choices comes confusion over what's the best route. Unfortunately, many well-meaning stroker fans buy first and then do their research. The smart movers step more carefully on their way to assembling the ultimate street motor. There are several pitfalls that need to be addressed, especially if you choose to go the route of buying individual parts in search of the righteous deal.

In the next few pages, we'll look at some of the most important areas of stroker science, such as the weighty issues of balancing, the bob weight bed of snakes, and that interconnected issue of rod length-to-stroke relationships. So follow along as we show you what's involved with slapping a big arm in your favorite V-8.

Crankshafts

Cast cranks are fine for low-rpm work, but this is what happens to cast cranks at high engine speeds where load increases geometrically until something breaks. High horsepower and high rpm demand a 4340 steel crankshaft.

Cast cranks are fine for low-rpm work, but this is what happens to cast cranks at high engine speeds where load increases geometrically until something breaks. High horsepower and high rpm demand a 4340 steel crankshaft.

When we talk about stroker motors, it really is all about the crankshaft. But there's more to this than just cramming a big crank in a small motor. There are many issues, but we'll limit this discussion to strength, weight, and applications.

Let's start with a realistic approach to applications, since that will have an impact on the selection process and the cost of the parts. If a mild street motor is all you're looking to build, then a cast crank can be very affordable. Scat, Eagle, and others build very affordable parts. There are plenty of stroker cranks out there for the more popular small-blocks at less than $200. From a metallurgy standpoint, nodular iron cast cranks are more flexible than they are given credit for, and rpm has a big effect on durability. The higher the peak horsepower rpm point, the stronger the crank you should buy.

Forged cranks are stronger than cast. At the top of the affordable forged list are 5140 forged-steel cranks, but they're not as strong as 4340 steel. You'll hear about both twist and nontwist cranks with theories abounding about which is better. The point is that if you buy a 4340 steel crank, it's going to be plenty strong either way. The price difference is directly related to where these cranks are forged. The lower-cost steel cranks are forged in either Argentina or China, while U.S.-made cranks such as those from Crower or Lunati, for example, cost more but are generally of higher quality. You get what you pay for. We don't need to discuss billet cranks because if you think you need a billet then you already know the price of admission.

When considering building a stroker motor, the best choice is to buy a complete rotating package. This makes the critical decisions concerning rod length, piston compression height, and balancing much easier. If you choose to purchase your parts separately, you'd better have a lock on all those (plus about a dozen more) details because it only takes one small oversight to bore a stroker-size hole in your wallet. Companies like Holley sell cranks, rods, and piston combos for nearly any engine.

Definition:

Offset-Grinding

You can increase the stroke on any crank by offset-grinding the rod journal, which moves the journal centerline away from the crank centerline. This also reduces the overall diameter of the rod journals, often requiring custom connecting rods to match.

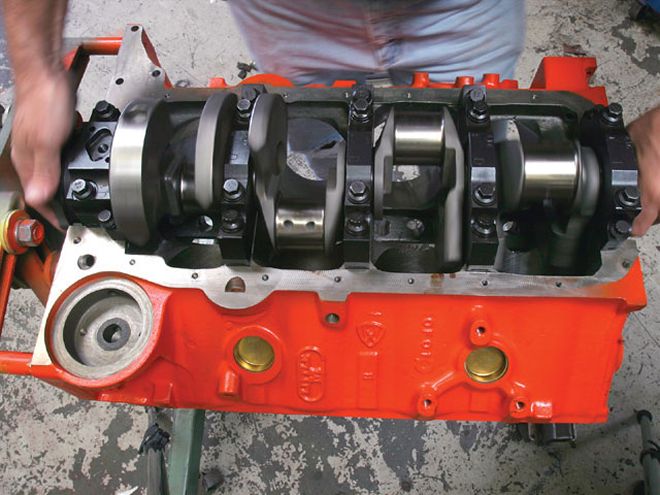

Cylinder Blocks

The difficulty with a longer stroke is that the connecting rod travels in a wider arc. The arrow points to where this small-block Chevy block was relieved to clear the connecting-rod bolt. This is delicate work, since water jackets lurk near where this grinding takes place on a production block.

The difficulty with a longer stroke is that the connecting rod travels in a wider arc. The arrow points to where this small-block Chevy block was relieved to clear the connecting-rod bolt. This is delicate work, since water jackets lurk near where this grinding takes place on a production block.

The majority of street stroker engines built in the world today are based on production blocks. The trick for stuffing a stroker crank in an OE block is all a question of architecture. Assuming the crank main journals will fit or can be machined to fit the block in question, the next biggest hurdle is whether the counterweights will clear. Often, connecting rods can be troublesome because they tend to hit either the side of the crankcase, the camshaft, or both. This necessitates machining the block to clear the rods or custom stroker-style rods. A longer stroke may also require a custom oil pan to clear the additional width of the rotating assembly.

If you're really serious about a stroker motor, the ideal move may be to step up to an aftermarket block. While the more popular engines like the small-block Chevy and Fords offer a dizzying assortment, there are more blocks coming on line every day. There's even an aftermarket block from Indy Cylinder Heads for the AMC 401. For stroker motors, these aftermarket blocks generally offer more crankcase room for longer strokes accompanied by huge bores. The standard-deck-height Ford Racing 460 block, for example, makes up to 598 ci with a bore of 4.600 and a 4.500-inch stroke.

Monsters of the Midway

We thought it would be fun to look inside the biggest automotive V-8 race engines on the planet. There may be bigger ones out there, but it would be tough to top a 900ci Hemi Ford engine that Jon Kaase built for a tractor-puller customer. According to Kaase, the normally aspirated engine makes a neck-straining 1,400 lb-ft of torque. At 900 ci, that means each cylinder displaces 112.5 ci-or just a little bit less than three times those of a 5.0 Mustang V-8.

Aftermarket Blocks For Stroker Applications

Here are some common blocks and deck heights. The ones listed as "tall-deck" have deck heights taller than stock to accommodate longer rods for long-stroke cranks. There are many more part numbers available than those listed, as many blocks are also available with various bore sizes and main-cap styles.

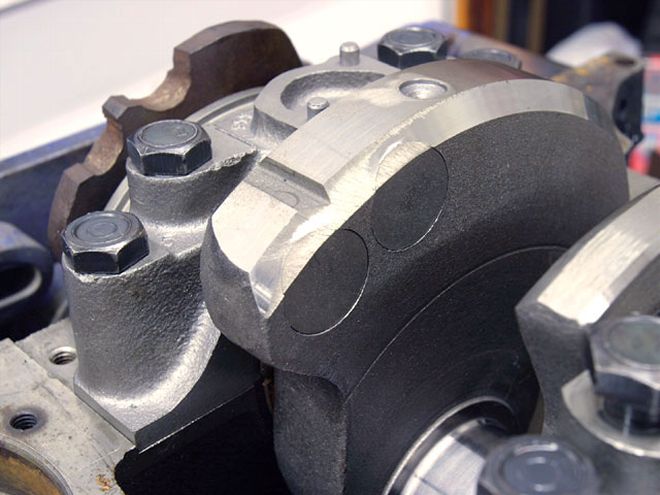

Internal versus External Balance

Offset weights on a damper or flexplate are required for externally balanced engines. These pieces are for a 383ci small-block Chevy. The small-block Ford, 400ci small-block Chevy, and 454 Chevy big-blocks are just some examples of engines originally built as externally balanced engines.

Offset weights on a damper or flexplate are required for externally balanced engines. These pieces are for a 383ci small-block Chevy. The small-block Ford, 400ci small-block Chevy, and 454 Chevy big-blocks are just some examples of engines originally built as externally balanced engines.

Additional stroke also means more weight swinging in a wider arc. But often, there is not room inside the crankcase for longer or heavier counterweights on the crankshaft. One solution is external balancing, where additional counterweight is placed at the damper and at the flexplate/flywheel. By placing this offset weight at each end of the crank, less is needed. However, at higher engine speeds, this additional offset weight can contribute to harmonic problems. This is why most forged cranks are designed for internally balanced assemblies where the weight is located on the crank counterweights themselves and not on offset weights on the damper and flywheel.

While on the subject of dampers, we spoke with Scat owner, Tom Lieb, who is very vocal about the effect of heavy dampers on crankshafts. While these components are designed to dampen the oscillations of the crank, it's also important to remember that under maximum acceleration, you must accelerate the damper with the engine. A heavy damper tends to resist this effort, creating a twisting motion of its own. A lighter damper creates less stress on the crank snout and is easier to accelerate. It's best to discuss your application with your crankshaft manufacturer for damper recommendations, but smaller in diameter and lighter is generally better than big and heavy if there is high rpm in your engine's future.

Deck Heights

The chart below lists deck heights for the most popular production V-8 engines. Deck height is defined as the distance from the crankshaft centerline to the height of the head-sealing surface. Aftermarket blocks often come with taller deck heights to allow longer rods to be used with longer strokes.

Production Block

Deck Heights

ENGINE DECK HEIGHT (inches) AMC 401 9.208 Buick 455 10.57 Cadillac 425/472/500 10.815 Chrysler small-blocks 9.585 Chrysler 383 "B" 9.980 Chrysler 440 "RB" 10.725 Chevy 283-400 9.025 GM Gen III LS1 9.240 Chevy 454 pass. 9.800 Chevy big-block truck block 10.20 Ford 289-302 8.206 Ford 351W 9.480 9.503 '71-'72 Ford 390-428 10.17 Ford 429/460 10.300-10.322 Olds 455 10.620 Pontiac 389-455 10.24

Adding stroke will automatically increase compression even if no other changes are made to the engine. This is because the piston now travels farther from bottom to top. As an example, a 350ci small-block with a 10.0:1 static compression ratio will jump 16 percent to 10.64:1 merely by adding 0.270 inch of stroke from 3.48 to 3.75. Piston deck height, or piston deck clearance, also affects compression.

Adding stroke will automatically increase compression even if no other changes are made to the engine. This is because the piston now travels farther from bottom to top. As an example, a 350ci small-block with a 10.0:1 static compression ratio will jump 16 percent to 10.64:1 merely by adding 0.270 inch of stroke from 3.48 to 3.75. Piston deck height, or piston deck clearance, also affects compression.

Piston deck clearance is determined by adding half the stroke to the rod length and the piston compression height. Often, the block will be slightly taller, allowing for additional piston-to-head clearance. As an example, a small-block Chevy has a production block deck height of 9.025 inches, though blocks are often cut for less deck height. Taking half a 3.750-inch stroke, plus a 5.700-inch rod, plus a JE piston compression height of 1.425 gives you 9.000 inches. When the engine is mocked up and the piston is found to be 0.010 inch below the deck surface, the actual block deck height would be 9.010 inches.

Decking and Static Compression

Below is an example of how compression ratio would change on a Buick 455 with different block deck heights and a fixed piston compression height. These aren't all the variables, but it gives you an idea.

Stock block deck height: 10.570

Piston compression height: 1.985

Rod length: 6.6

Stroke: 3.900

Rod Length and Piston Compression Height

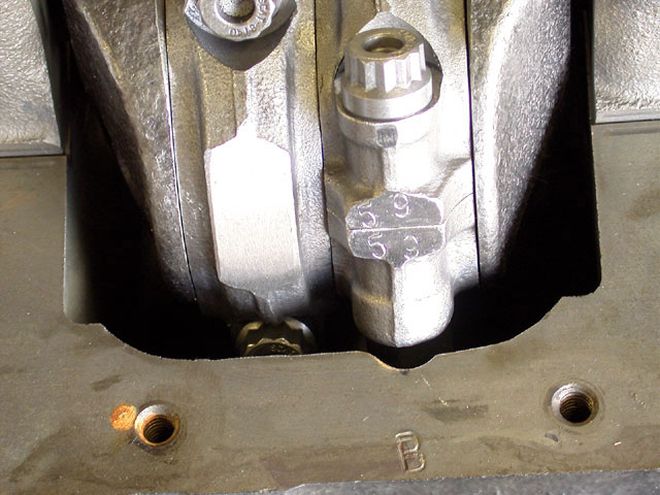

Many companies like Crower, Eagle, Lunati, Scat, and others sell stroker rods that use capscrew bolts rather than bolts and nuts. This creates more room for tight cam-to-connecting-rod clearances.

Many companies like Crower, Eagle, Lunati, Scat, and others sell stroker rods that use capscrew bolts rather than bolts and nuts. This creates more room for tight cam-to-connecting-rod clearances.

While purchasing stroker kits is the best way to eliminate expensive mistakes, it's still worthwhile to know how various combinations of connecting-rod length and piston compression heights are achieved. Rod length is simple to visualize as the distance between the centerlines of the big and small ends of the rod, and piston compression height is similarly easy: It is the distance from the wristpin centerline to the top of the flat portion of the piston. Piston domes or dish dimensions are not considered in the compression-height distance.

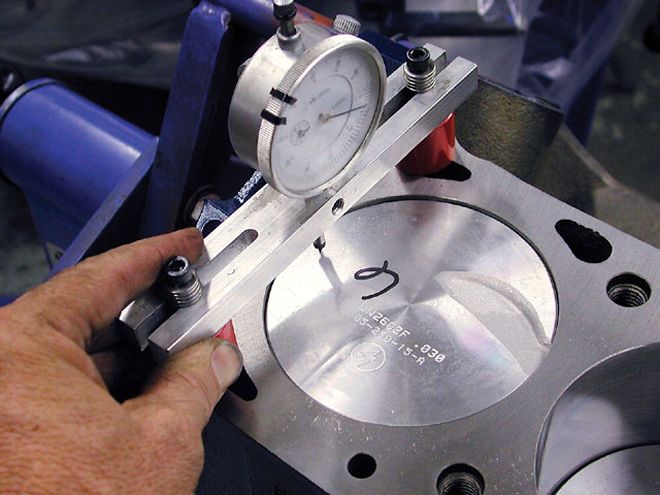

To determine if a given stroke, rod length, and piston will fit, the math is also easy. All you do is add half the stroke, the rod length, and the piston compression height. This length should not be more than the block deck height. As an example, let's take a big-block Chevy with a block deck height of 9.80. Let's say we already have a crank with a stroke of 4.250 and a rod length of 6.385 inches. What should the compression height be for our piston? Let's add half the stroke and the rod length (2.125 + 6.385 = 8.51) and subtract this figure from the block deck height (9.800 - 8.51 = 1.290 inches). Most piston manufacturers produce pistons with slightly shorter compression heights to accommodate milling the block to ensure the deck is flat and parallel to the crank centerline. JE Pistons, for example, specs all its big-block Chevy pistons with a 0.020-inch shorter 9.780-inch deck. Subtracting 0.020 from our 1.290-inch figure gives us 1.270 inches, which is exactly what JE lists for a piston for this specific application. It's that simple.

When determining what parts to run, it's always best to mock up your engine first and measure block clearances and the deck height of a given crank, rod, and piston assembly first to ensure a proper deck height. We had a friend make these 0.0010-inch undersize aluminum wristpins to mock up a small-block Chevy.

When determining what parts to run, it's always best to mock up your engine first and measure block clearances and the deck height of a given crank, rod, and piston assembly first to ensure a proper deck height. We had a friend make these 0.0010-inch undersize aluminum wristpins to mock up a small-block Chevy.

There has been more written about rod length-to-stroke ratios than the subject deserves. To condense it to a few sentences, longer rods offer no power advantage but do offer some durability enhancements. The easiest way to look at this relationship is with a rod length-to-stroke ratio (R/L). Merely divide the rod length by the stroke. A 454 Chevy with a 4.00-inch stroke and 6.135-inch rods has a R/L of 1.533:1. Conversely, a 302 small-block Chevy with a 3.00-inch stroke and 5.70-inch rods enjoys a R/L of 1.9:1. According to David Reher of Reher & Morrison Racing Engines, his years of Pro Stock engine development have revealed no power advantage to longer (or shorter) rods, but longer rods do reduce the side loads that push the piston into the cylinder wall on the power stroke. While there is no rule of thumb, a R/L of 1.55 to 1.6:1 is a good ratio. One of the quandaries facing stroker-motor builders is that a longer stroke often leaves little room for longer rods in production-deck-height engines, which is why tall-deck blocks are available.

Effect of Stroke on Static Compression Ratio

Adding stroke to any engine will increase the static compression ratio even if no other variables change. This is because compression ratio is calculated by comparing the volume of the cylinder with the pistons at bottom dead center (BDC) versus the volume of the cylinder with the piston at top dead center (TDC). If we increase the length of piston travel by adding stroke, this increases the volume of the cylinder with the piston at BDC. Even though the volume at the top of the piston travel does not change, the piston has compressed a larger cylinder volume into the same space, increasing the compression ratio. This is why short-stroke engines need really small chambers or a piston dome to increase compression. Just as a point of reference, increasing cylinder bore also increases static compression ratio, since we're now working with a larger volume due to the increased bore.

This chart uses a big a big-block Chevy as an example because this engine offers such a tremendous range of stroke length. Variables that we used to compute compression ratio include a 4.250-inch bore, a 118cc combustion-chamber volume, a piston deck height of 0.010 inch, a compressed head-gasket thickness of 0.042 inch, and a 30cc piston dome volume.

Stroke Static Compression Ratio (inches) 3.76 9.73:1 4.00 10.29:1 4.125 10.58:1 4.250 10.87:1 4.375 11.16:1 4.500 11.45:1 4.750 12.03:1 5.00 12.{{{62}}}:1Bob Weight

Balancing a stroker crankshaft assembly is usually an easy affair, but it can get complicated if you have purchased a separate crank, rods, and pistons. The problem is that crankshaft counterweights are designed to accommodate a given amount of weight for the piston and connecting rod. The big variable is the length of the connecting rod. Longer connecting rods weigh more, which can affect the balance. Crank builders and balance shops use something called bob weight to manage these combinations. Bob weight is the weight attached to each connecting-rod throw on the balance machine that simulates the amount of weight for a pair of reciprocating piston assemblies. Often, you will see a particular crankshaft listed for a given stroke with a given amount of bob weight, expressed in grams, such as 1,800 grams.

To boil it down to the essentials, bob weight is 100 percent of the rotating assembly weight plus 50 percent of the reciprocating weight. Rotating weight consists of the big end of the rod, the bearing, and perhaps a few grams of oil. The reciprocating weight is equal to the small end of the rod, piston, wristpin, rings, wristpin locks (if used), and also a bit of oil. Let's say our rotating weight for a small-block Chevy is 474 grams and the reciprocating weight measures 872 grams. To find the bob weight, we add 474 plus 436 (half of 872) to equal 910 grams. We multiply this by two because we have to balance the crank for a pair of rods and pistons to come up with 1,820 grams. If the crankshaft has a bob weight of 1,850 grams, it's easy to drill a small hole in the counterweight to reduce the counterweight to equal 1,820 grams.

Mallory metal is a tungsten alloy that is 1.5 times heavier than lead. It's also verrry expensive, so don't plan on using a lot of it.

Mallory metal is a tungsten alloy that is 1.5 times heavier than lead. It's also verrry expensive, so don't plan on using a lot of it.

If the crank counterweight is only good for 1,800 grams, we either have to lighten the mass of our piston assemblies or add Mallory (heavy) metal to the crank throw to increase its weight up to 1,820 grams. Enthusiasts get into trouble when they assemble mismatched parts that require expensive machine work to balance properly. This is where balancing can more than offset any savings from these parts.

Bore and Stroke Chart

To find displacement, merely follow the bore from the left to match up with the stroke amounts listed across the top of the chart, match the up and you have your displacement. For example a 4.50-inch stroke with a 4.50-inch bore equals 572 ci.