The engine builds typically found in HPP are aimed at making power, either pushing the envelope for streetable performance or just trying to find the boundaries of the Pontiac V-8. Both have become easier in the past decade thanks to a flourishing aftermarket that provides hardware to improve output and minimize the catastrophic failures that can often follow. But the pursuit of ultimate output isn't for everyone; in fact, it's probably not even for the average hobbyist. That guy wants his car to be as fast as possible, but he also wants it to start and idle when Sunday finally comes around and he has time to take it out. That guy is looking for balance.

Charlie Chandler could be considered "that guy." He's been a fan of muscle since he was barely old enough to drive, back when some of the greats were still rolling off assembly lines. Since that time, he's had the opportunity to own quite a few musclecars, but drag racing isn't really part of Charlie's regular routine. As an M.D. and a family man, much of his time is spoken for, but living in Los Angeles does provide a steady flow of sunny days to motor in classic iron. So when he spotted a '69 GTO convertible sitting forlornly on a Santa Monica side street, he knew he'd found the perfect street machine. It took six years to finally get the Goat away from the previous owner, and then he had to deal with the blown-up factory 400. Even though it was a base engine rated at 350 hp, it was the factory-installed numbers-matching block. Sadly, it had been mortally wounded. Being a four-speed convertible, Charlie felt that it would be worth the effort to try and preserve some measure of originality, so he shopped around for a properly coded block and a shop to build it.

Finding the shop was simple: Charlie already knew the guys at Westside Performance in West Los Angeles, and he knew that proprietor Ted Toki had spent the better part of the last 35 years building engines for hot rods. In fact, Ted had spent that time building entire cars, many of them for the strip.

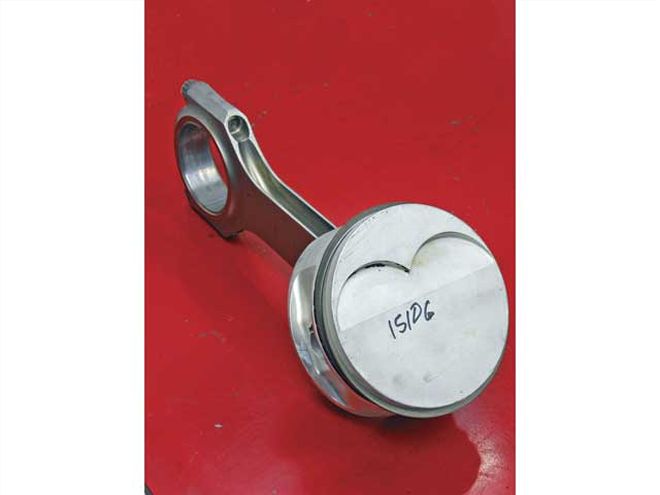

The biggest deviation from stock in this 400 can be found in the reciprocating assembly. Stock Pontiac pistons and rods will be replaced with custom Ross forged slugs and SCAT H-beam rods spec'd for a big-block Chevy (BBC). The advantage of this change is primarily weight reduction, though it also provides the opportunity to make other improvements.

The biggest deviation from stock in this 400 can be found in the reciprocating assembly. Stock Pontiac pistons and rods will be replaced with custom Ross forged slugs and SCAT H-beam rods spec'd for a big-block Chevy (BBC). The advantage of this change is primarily weight reduction, though it also provides the opportunity to make other improvements.

Westside Performance itself is a bit of an anomaly, at least in the heart of a big city. Few traditional speed shops have survived the roller coaster of economics, fuel shortages, smog police, and real estate booms that have occurred since the '60s, even in the center of the L.A. car culture, especially in an area as desirable as the patch of land occupied by Westside. But there it is, much as it has been since the '60s.

The most unusual part of Westside is that it remains a full-service speed shop, not just a retail store for aftermarket goods. In back, off the alley is a garage where any of the items sold inside can be installed, and this is also where the engines are assembled. This is the heart of Westside's R&D, which Ted sums up succinctly: "Most of our stuff is based on trial and error. We've had it either work or not work." After 35 years, they've got a pretty good idea of what works.

Ted spends a lot of his time these days working out combinations that are beneficial for street cars, trying to extract the most power and durability from engines that will see regular use. Being somewhat old school, Ted always has an eye on the budget as well. This would certainly not be the first Pontiac for Ted. He's been messing with them for decades, along with some of the other GM powerplants like Olds and Cadillacs. Walk around the back of the shop for a few minutes and this is quickly confirmed, as shelves filled with core parts, many of them Pontiac, line the walls.

This particular build began with its own problems. First, the block the Doc had located to replace the original was junk. Boring it (again) had actually uncovered a tiny casting void that became a pinhole, which went all the way through to the water jacket. Yet another block was sourced, only to find that it had already been bored 0.060-inch over previously and not very well. Charlie was about to start the search for a third when Ted came up with a plan.

Boring past 0.060-inch over for most engines is pushing it, though Toki says the 400 Pontiac usually has enough material to go even farther. But for this build, taking the bores just a little bit more, 0.065-inch total, would do the trick. That would bring each bore to a 4.185-inch diameter, the same as a 0.035 over 455. The significance of that relationship is that modern, high-performance piston rings for that bore size are already sitting on a shelf somewhere, just waiting to be slipped over a custom piston and into the 0.065-inch over Pontiac 400, as a 0.060-over Chevy 400 small-block is the same size.

At the big end, the BBC H-beam is much more compact than the stock rod, and it uses cap screws rather than traditional nuts and bolts, providing additional clearance. This isn't really an issue with our 400 but could be helpful for some stroker combos.

At the big end, the BBC H-beam is much more compact than the stock rod, and it uses cap screws rather than traditional nuts and bolts, providing additional clearance. This isn't really an issue with our 400 but could be helpful for some stroker combos.

Ted had a few other tricks to employ for the build. While they were having custom pistons made, he opted to ditch the heavy and not-so-durable stock Pontiac connecting rods for a set of low-cost aftermarket H-beams intended for a big-block Chevy (BBC). The SCAT rods measure 6.800 inches center-to-center and are a common item for BBC builds. They happen to be just a bit longer than a stock Pontiac (6.625-inch) rod but use a much smaller 2.20-inch rod-journal diameter than a stock Pontiac (2.250-inch). Using BBC rods in Pontiac V-8s is not a new idea, as Ted points out. "The long rod is a common-use item, and best of all, it's cheap. Plus, you can buy the H-series bearing with no drama--that's the one with the extra chamfer. Getting Pontiac-specific stuff is harder." Toki further explained that turning the Pontiac crank's rod journals down to 2.20-inch from 2.250 also adds the benefit of less drag through reduced bearing speed. Oiling is improved at the same time, and as a bonus, there is a small rotating-weight reduction.

Using a rod that is longer than stock is a fairly common performance-engine builder's technique, often to improve the rod angularity realized as the piston travels down through the bore on the power stroke. The actual benefits have been debated for years, but Ted likes the fact that the piston can be made shorter with a longer rod, reducing its weight even further than using a lightweight forging in stock dimensions. Positioning the wristpin higher in the piston (closer to the crown) also improves the stability of the piston as it changes direction at the top of the stroke, allowing the piston skirt to be shorter as well. The BBC wristpin is actually a shade larger in diameter than the stock Pontiac piece, 0.990-inch to the Pontiac's 0.9802-inch, but the Ross pin employed here uses a thinner wall to shave weight, yet it's still stronger than stock thanks to improved materials.

The pistons come from Ross, a manufacturer well-versed in creating high-performance pistons for traditional Pontiacs. In general, forgings are much stronger than cast pistons but often carry a weight penalty thanks to their increased density. Yet high-performance forgings often weigh less than a factory-cast piston for the same application as a result of more accurate piston design--the strength of each piston is increased by bolstering the areas that require it the most while also eliminating superfluous material and the unneeded weight it carries. Since the pistons for this 400 will be shorter than stock, even more mass will be eliminated.

Why make such a big deal over eliminating weight from the reciprocating portion of the engine? As Ted puts it, "Getting the weight out just makes life easier on all the other parts. It's more zen-like." He goes on to explain the specific benefits, primarily focused on the reduced load placed on what may be the most stressed component in the engine: the connecting-rod bolts. Every time a piston reaches top dead center (TDC) and changes direction to head back down the bore, the rod bolts must bear the brunt of containing the inertia each piston/rod combo holds as it travels upward. Think of the piston and rod as the weight on a slide hammer being flung against the end of its travel. Reducing that weight reduces the shock to the rod bolts, and the rod itself for that matter, with each revolution.

When the crank journals are machined down to the BBC dimension of 2.20-inch (from the stock 2.250-inch), the radius cut (arrow) must be recreated on the fillet. Any competent crank grinder can perform the necessary machining to create the required radius.

When the crank journals are machined down to the BBC dimension of 2.20-inch (from the stock 2.250-inch), the radius cut (arrow) must be recreated on the fillet. Any competent crank grinder can perform the necessary machining to create the required radius.

Since the good doctor wasn't looking for a strip terror with license plates, the top end of the 400 is fairly tame. The aluminum Edelbrock heads are untouched other than having a complete inspection, and the Engle hydraulic cam remains on the low side of 0.500-inch lift, plus it's 112-degree LSA helps keep the idle reasonable. Ted had confidence that the combo would still make healthy power, and the testing on the dyno at Eddings Engine exceeded his goals for the project.

Within days of the dyno session, the 400 was between the fenders of the GTO, racking up street miles. Initial feedback indicates that the Pontiac's manners in traffic are completely acceptable, and the torque of the fresh 400 can overcome the puny 14-inch rubber without even trying. This combo makes reliable power, provides some eye-pop under the hood, and was built using a block that otherwise would have been cast aside. Not to mention the fact that if the owner ever wants to go faster, the foundation is already in place to do it with minimal parts changes. It's a win/win situation all around.

ON THE DYNOAll testing was performed on a DTS PM15 dyno at Eddings Engine Rebuilding. Ambient temperature was 85 degrees, and Unocal 91-octane pump gas was used.

WESTSIDE PONTIAC 400 ENGINE Corrected RPMCorrected TorqueHorsepower 3,0004762723,100483285.003,200486296.203,300484303.83,400485314.13,500488325.13,600490336.13,700492346.63,800490.63553,900487.2361.74,000485.4369.74,100483.8377.74,200483.6386.74,300483.8396.14,400481.7403.54,500478.3409.84,600470.7412.34,700466.3417.34,800465.5425.54,900462.3431.35,000460.1438.15,100456442.85,200449.1444.75,300438.7442.75,400425.5437.55,500413432.5

Engine Specs Engine Displacement:412.46ciHorsepower:444Torque:492Bore/Stroke:4.185x3.75-inchBlock/Crank Combo:'69 Pontiac 400 block, modified; stock-cast 400 crank modifiedBore/Stroke Ratio:1.11:1Rod/Stroke Ratio:1.81:1

Bottom End Block:'69 GTO 400 castingPrep:Cylinders bored 0.005-inch over previous 0.060-inch overbore to 4.185-inch; deck resurfaced (0.010-inch), align-hone checked and found to be in specDeck Height:Block decked 0.010-inch; new pistons designed for zero-deck conditionCrank:Stock Pontiac 400, '69Prep:Rod journals machined to 2.20-inch with BBC-style radius, mains cut 0.010 underBalancer, Brand:Pioneer standard replacementType:Stock elastomerRods:SCAT forged-steel H-beam for BBCRod Length:6.800-inchPrep:None; check bolt stretch and side clearanceBearings:Clevite 77, stock replacement BBC for rods; stock Pontiac 400 0.010-under for mainsPrep:Main-bearing oil holes enlarged to match block oil holesPistons:Ross custom-forged flat-top with valve reliefsPrep:Check and install to connecting rods with SpiroloxPiston-to-Deck Height:ZeroPiston Pins:Ross spec'd for BBC with full-floating pinsRings:Akerley & Childs single-moly; 1/16, 1/16, 3/16Preparation:Set endgap to 0.020-inch, top ring; 0.022-inch, second ringRod Bolts or Studs:ARP cap screws spec'd by SCATHead Bolts or Studs:ARP head-bolt kit spec'd by Edelbrock

Oiling System Windage tray:Stock Pontiac full-length Crank Scraper:NoneOil Pan:Stock '69 GTOOil Pump:Melling high-volume mechanicalPrep:Disassemble and deburr; weld pickup

Heads Type, Brand:Aluminum Edelbrock Performer RPMChambers:Closed 72ccHead Mods:None, out-of-box stockCompression Ratio:10.65:1Valves:As supplied by Edelbrock, stainless steelIntake Size:2.11-inchExhaust Size:1.66-inchAngles Used in Valve Job:As performed by EdelbrockMods:NoneValve Guides:Edelbrock, manganese bronzeValve Seals:Edelbrock Viton 11/32-inchValvesprings:EdelbrockRocker Studs:7/16-inch studs, ARPRocker Arms:Harland Sharp aluminum adjustable full-rollerRocker-Arm Ratio:1.50:1Pushrods:Smith Brothers, 5/16-inch

Cam Brand:Engle flat-tappet hydraulicDuration at 0.050:236/236-degLift:0.494/0.494-inchCenterline:112-degLobe Separation Angle:112-degInstalled Position:Straight upLifters:Engle hydraulic

Induction Carburetor:Holley HP SeriesFlow Rating:750-cfmJets:Primary, #70 with 32 air bleed; secondary, #74 with 32 air bleedPower Valve:65Fuel Pump:Carter mechanical, 120-gph, free-flow, 6-psiFuel-Line Size:3/8-inchIntake Manifold:Edelbrock Performer RPM, dual-planeMods:None

Ignition Distributor:MSD Pro-BilletAmplifier:MSD 6AL (7AL-2 for dyno test)Coil:MSDWires:MSD 8.5mmTotal Timing:38-degInitial Advance:17 degrees BtdCMechanical Advance:21 degreesVacuum Advance:None

Exhaust Headers:Doug's Headers full-length four-tubePrimary Tube Diameter:1.75-inchPrimary Tube Length:34-inchCollector Size:3.5-inch

Gaskets Brand:SCE for round-port Pontiac