To those interested in power output, nothing has the attraction of a supercharger. Forcing atmosphere into an engine makes it take a charge out of proportion to its displacement, and, with that, produce power out of proportion to its size. There are many types of supercharger systems used in automotive applications, from turbos to positive displacement Roots-style blowers, to beltdriven centrifugal units. Each has their pros and cons, with turbos getting a nod for efficiency, but often presenting an installation nightmare. Traditional Roots blowers are capable of effective low-rpm boost, though they are too ostentatious for some and are no lightweights. Beltdriven centrifugal blowers have become popular for several reasons: The systems are relatively easy to install, offer increasing boost with rpm, and the big bottom line is they make serious power.

The leader in Mopar musclecar centrifugal blowers is a company called The Supercharger Store. We looked longingly at some of their well-designed products at various Mopar events for several years now, and decided to finally take the plunge into the realm of boosted power. The Supercharger Store systems are based on the ATI Procharger line of blower units, superchargers that are well proven in drag racing and street applications. Most of the ATI blowers are fully self-contained, meaning they carry their own internal lubrication supply, eliminating the need for plumbing pressure and return lines between the blower and the engine. The Supercharger Store has many variations of blower systems and components specifically for Mopar applications, so we had many options to consider when formulating a plan for a blown big-block Mopar.

Popular kits are based on blowers of various capacities, depending upon the boost level and power objectives. Initially we were going to go with a basic street kit, built around the 1,400-cfm D1SC Procharger. Later, we reconsidered the project and settled upon the much larger capacity F1-R, a hotter version of the 1,525-cfm F1, rated for 2,000 cfm. This unit would be enough to easily produce high boost in a 440ci engine, and yet have the capacity to handle the greater needs of a high-output stroker combination if we later choose to go that route. Boost pressure is dependant upon sizing as well as rpm, and the rpm can be adjusted within the unit's operating range by the selection of blower pulleys. Our intention was to use the F1-R on a typical bracket race/street style 440 and spin it for high boost. Our engine makes peak power naturally aspirated at roughly 6,000 rpm, with a redline of 6,700 rpm, so those points are established. The drive pulley ratio can be determined by the operating rpm range, the displacement, and the targeted boost. The Supercharger Store has the data to match sizing for the required goals.

Engine Mods

Our prospective blown engine was pretty typical of a hot street or strip 440, built on a .030-inch overbored factory block, with 10.3:1 compression, Edelbrock heads, and a Comp Cams solid lifter cam. The engine produced a best of 550 hp on the dyno, a very respectable number for a relatively inexpensive and simple combination. It would serve to be a good testbed of the Procharger's potential, but we needed to make a few changes to prep it for blower duty, besides simply bolting on the blower.

We intended to run fairly high boost levels, at which the engine's 10.3:1 compression ratio would be too high, especially on pump gas. To get the ratio closer to the 8:1 ratio recommended by The Supercharger Store, we needed to take a good two points of compression out. A piston change is the obvious solution, but we already had a fine-running 440 bottom-end, and were not too eager to tear it down and toss out the pistons in favor of custom dished replacements. Weighing everything involved, including the full tear-down, pressing the replacement pistons on, new rings, and rebalancing the short-block, we weren't too far from building a new short-block.

We found the solution from a company called Flatout gaskets, makers of unique rubber-coated copper head gaskets, among other sealing products. We had used a set of these copper gaskets in another build-up, and were impressed they sealed both compression and fluids perfectly, without the aid of O-rings or additional sealant. Flatout manufactures these gaskets in a wide variety of thickness, including a 0.125-inch thick version that can be used as a cylinder head spacer in conjunction with conventional gaskets. This spacer would add over 30 cc of volume to our combination, enough to drop the compression ratio to 8:1. To aid in the cylinder head clamping, the head bolts were replaced with a set of Milodon head studs. Another point to consider is to ensure the cylinder head alignment dowels in the heads are sufficiently long to accommodate the thick gasket pack. We ended up replacing the dowels in our engine.

The only other change to the 440 was replacing the camshaft with a grind more suited to a blown application. The Supercharger Store recommends a wider than normal lobe separation angle to optimize the engine for boost. This is a fairly general recommendation that follows established practice with blown engines, serving to open the exhaust valve sooner, and reduce overlap. In theory, opening the exhaust valve earlier helps deal with the greater volume of gasses produced with supercharging. The reduced overlap is beneficial because overlap scavenging is not critical for cylinder filling since a blower provides the fill. The wider lobe separation is well accepted, so we bit the bullet and replaced the cam, going from a 110-degree lobe separation to 114, with no other changes in cam specs. We have not done a back-to-back test of lobe separation angles to verify the benefit, but we'll go out on a limb and say it probably isn't necessary in most cases with typical street cams.

With the engine reassembled, what was left was simply bolting on the blower kit. The Supercharger Store needs to be complimented on the completeness of their kit, since every nut and bolt we needed came in the box, with no runs to the hardware store required. Essentially, an adapter bolts to the damper, and then the blower bracket is mounted in place. Next, the blower bolts onto its mounts, and from there it is just a matter of slinging the belt in position and plumbing. With their street kits, a blow-off valve is fitted to the inlet tube. For high capacity "race" systems, a large, high-flow, blow-off valve is provided, which we got with our kit. The valve needs to be "T-d" into the induction pressure pipe, and this requires welding an included tube and flange in place.

The Test

It was an exciting day when our 440 arrived at Westech for testing. The blower gave the engine a serious look that suggested there was going to be quite a display of power. We trimmed the 440 out with a set of high-flowing tti step headers, and an MSD distributor and wires firing Denso Irridium plugs. Both exhaust flow and ignition are areas not to be neglected when courting blown horsepower. We plumbed in The Supercharger Store's water-injection system (see sidebar), and filled the reservoir tank with a dilute water/methanol mixture, actually windshield washer fluid. It all looked like a go, and, sure enough, the 440 fired and settled into an idle nicely. Taking a conservative approach, the ignition timing was set to just 25-degrees total advance, about 10 degrees less than the best normally aspirated power setting.

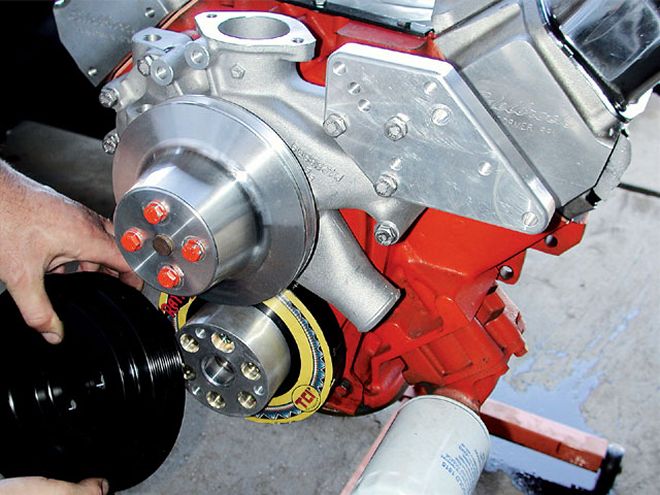

With the cam and compression changes made, all that was left was to bolt-on the blower. The drive adapter and crank pulley bolt right in place on the damper.

With the cam and compression changes made, all that was left was to bolt-on the blower. The drive adapter and crank pulley bolt right in place on the damper.

To establish a baseline before running the engine in the blown configuration, the engine was shut down, and the blower belt and air hat removed. We ran a baseline and found 421 hp at 5,600 rpm, over 125 hp less than the best numbers this engine has shown before. Between the two-point drop in compression ratio, the four-degree wider lobe separation and the 10-degree retarded timing, it was not surprising. The belt was reinstalled, and we were ready to try boosted power. Initial problems involved getting enough fuel flow from the carburetor to supply an adequate mixture. Eventually, we installed the largest 4150 carb we had available-a Race Demon RS with 1,050-cfm venturi sleeves, fitted with power valves at both ends and very large jets. We were only making short static pulls at a given rpm point and boost level to gage air/fuel mixture up the range. We were experiencing some variation in boost levels, compounding by a lack of repeatability, which was causing difficulty with tuning especially at higher rpm. Dyno operator Tom Habryzk suspected belt slippage. We cranked the belt tensioner and continued.

As we carried on with the power sweeps, we saw quite a bit of boost variation from run to run. Tom pointed out that the serpentine belts can become problematic with high boost and big blowers. To help the situation, the belt was coated with VHT Track-Bite, and the tension wound the belt as tight as a violin string. We saw as much as 757 hp at 5,700 rpm and 13.5 psi of boost, but belt slip, even with all of these measures, made it a problem to let the engine run up. Finally, the belt skipped a rib and ended our test session. We later discovered the blower pulleys were not in perfect alignment, which may have aggravated the situation. We should have checked that, since there are shims from The Supercharger Store to readily adjust the alignment.

However, Tom pointed out that in his experience with many centrifugal blowers in higher boost applications, serpentine belts are often problematic, maintaining that a cogged beltdrive is the only way to go.

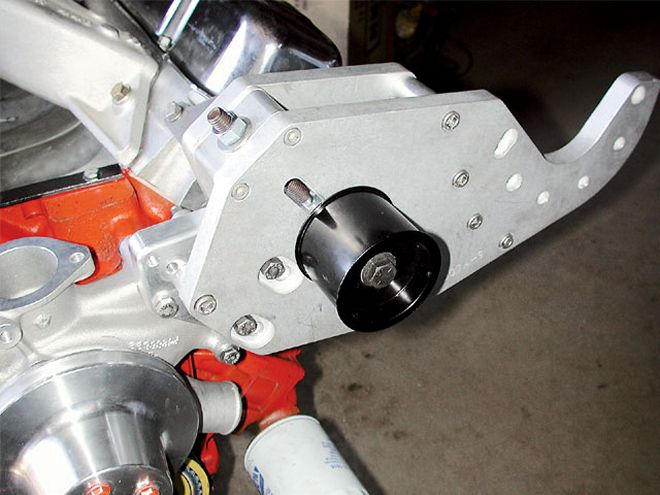

The blower's mounting bracket is easily assembled to the upper left of the engine, and The Supercharger Store even provides all of the hardware. The tensioner/idler is a heavy-duty design and integrated into the mount.

The blower's mounting bracket is easily assembled to the upper left of the engine, and The Supercharger Store even provides all of the hardware. The tensioner/idler is a heavy-duty design and integrated into the mount.

We conferred with Bob Woods of the Supercharger Store, and he agreed, pointing out that the larger blower kits he normally sells always come with a cogged drive. Chalk one up for experience. we blew it when ordering our setup and then opting for the larger blower later. We placed an order for the cogged drive, and in a few days were ready for another crack at the dyno. The pulley system directly replaced the serpentine setup, bolting on in minutes, and, once again, the 440 was ready to run. The cogged drive eliminates all potential for slip, reduces the tension required, and is just plain bulletproof.

Back at Westech, the 440 was again mounted to the dyno, and this time we were ready to let it run for the numbers. The potential had already been shown in our last test session with over 750 hp on the dial. With a cogged beltdrive offering the promise of full high-rpm pulls without slippage, we knew the 440 would deliver-and deliver it did. We wound the engine up to 6,400 rpm, and the boost just kept coming. A peak output of 878 hp at 6,300 rpm is pretty hard to argue with, especially considering the basic package below. We made several pulls that day, and the power number and boost level repeated like clockwork, run after run. Dialing in more timing than the 25 degrees we started with didn't show an improvement, so that's where we ended up. The Flatout head spacers sealed like a vault, and the 440 showed no signs of distress. For an engine this size, 878 hp is an all-out racing engine's output, but the engine ran just as docile at idle as before, in fact, even more so given the wider lobe separation and reduced overlap.

Dyno ResultsSuperFlow 902 Engine Dyno Tested atWater Injection

You may have noticed that our 440 combination was running high boost without the aid of an intercooler. It's a fact of physics that compressing a gas (air in this case) produces heat. In practical terms, that means more boost equals more heat in the incoming charge. It's well known that high-inlet air temperature saps power and encourages detonation, hence the need for a means of charge cooling, especially with a lot of boost. Cooling the air/fuel charge is typically accomplished by employing a heat-exchanging unit known as an intercooler. Essentially, an intercooler is a radiator through which the induction charge is passed and cooled by the temperature differential between the high-temperature inlet air and the cooling medium-ambient air in an air-to-air intercooler.

The system favored by The Supercharger Store is a departure from a conventional intercooler, and actually borrows from technology employed in supercharged WWII fighter aircraft-water injection. Water injection provides a cooling effect to the charge through another effect of physics, the latent heat of vaporization. As a highly-atomized liquid changes to vapor, the process consumes heat. The Supercharger Store's system provides a high-pressure pump that is triggered by a pressure switch, which in turn is referenced to boost. When the boost hits the prescribed pressure level, the pump sends high-pressure water to a fine-atomizing nozzle aimed at the blower intake. Water provides the cooling and also acts as a detonation suppressant. The kit is complete, with all of the fittings, tubes, an anti-siphon valve, and a fuel cell to serve as the holding tank.

With the water injection properly setup, Bob Woods of The Supercharger Store reports phenomenal power output on pump gas. Various kits are sized with nozzles designed to differ the fluid flow rate for different output levels, with some of the higher horsepower kits featuring two stages of injection for outputs of up to 2,000 hp. The system can be used with straight water or various concentrations of water/methanol mix. Bob recommends common windshield washer solution, which contains up to 25-percent methanol. Water injection is far from a new idea, but with the output capabilities of modern supercharger systems it's an innovative solution for power on pump gas.