The 1969 Pontiac Trans Am spent the day on the chassis dyno trying to get every last foot from a quart of gasoline. This is in sharp contrast to what these cars were designed to do. Even though '69 T/As are rare and desirable, the powerplant in this one is a pretty accurate representation of what you may find in more common models, thus it is a good candidate for this test.

The 1969 Pontiac Trans Am spent the day on the chassis dyno trying to get every last foot from a quart of gasoline. This is in sharp contrast to what these cars were designed to do. Even though '69 T/As are rare and desirable, the powerplant in this one is a pretty accurate representation of what you may find in more common models, thus it is a good candidate for this test.

In Part I of our primer on increasing the fuel efficiency of your Pontiac, we covered the theory of improved mileage. As stated, HPP would then put our hypothesis to the test. Bob Wise from RaceKrafters Automotive Machine originally arranged for the principal of Jones Pontiac-GMC in Lancaster, Pennyslvania, to loan us a late-'60s GTO that he owned. As things would go, though the car was not for sale, someone made him an offer he could not refuse, and our test car was hauled away to a new owner's garage.

Fortunately, RaceKrafters is well entrenched in the Pontiac community, and had no problem lining up another candidate for our exercise. Ed Birchall, also of Lancaster, owns a '69 Ram Air III 400 Trans Am with an automatic transmission. The car is mostly original and in unrestored form except for its engine. Birchall has owned it for more than 20 years, and shortly after taking possession, the R/A-III engine developed a rod/piston noise. Since Pontiac engines were still relatively easy to come by in the early '80s, he slipped a junkyard 400 short-block in the F-body's engine bay and put the original safely in storage. Being a grocery-getter-variety mill with a ton of mileage, it was not as powerful as the factory engine, but it ran well, did not smoke, and sounded excellent. Thus, big power numbers would not be the order of the day.

In 1974, with the implementation of more factory emission controls, the trade organization SEMA, which now stands for Specialty Equipment Market Association (back then it was Manufacturers instead of Market) ran a series of advertisements in hobby magazines such as Hot Rod, Car Craft, and so on. It stated, "A high-performance engine is an efficient engine. An efficient engine is a clean engine." The campaign was meant to erase the bad image hot rodders held in the minds of an ever environmentally aware public. SEMA's statement was prophetic since it can still be employed today, especially when it comes to decreasing the fuel usage of a hot Pontiac.

The 400 engine ran well, but proved to be a real gas hog. It traveled only 1.1 miles on a quart of gasoline. That would be 4.4 mpg under the test conditions of accelerating up to 65 mph from a stop and maintaining this speed until the carburetor ran dry. The linear air/fuel meter from the dyno showed at cruise the carburetor was creating a 12.5:1 air/fuel ratio. This was more than two complete ratios richer than stoichiometric. This term describes the mixture strength for the most complete chemical-to-mechanical energy conversion for the fuel. Unleaded street gas (we used 93-octane Citgo) has a stoichiometric value of 14.67:1.

The 400 engine ran well, but proved to be a real gas hog. It traveled only 1.1 miles on a quart of gasoline. That would be 4.4 mpg under the test conditions of accelerating up to 65 mph from a stop and maintaining this speed until the carburetor ran dry. The linear air/fuel meter from the dyno showed at cruise the carburetor was creating a 12.5:1 air/fuel ratio. This was more than two complete ratios richer than stoichiometric. This term describes the mixture strength for the most complete chemical-to-mechanical energy conversion for the fuel. Unleaded street gas (we used 93-octane Citgo) has a stoichiometric value of 14.67:1.

When we began this journey, we knew our results would be based upon the state of tune of our subject car. Ideally, for demonstration purposes, our sample Pontiac should run well with no driveability issue, but be representative of a typical tune-up a reader would have on their car. If by chance the calibration was perfect on our subject, then there would be no room for improvement.

Since we were unfamiliar with Birchall's '69 T/A, we did not know which category it would fall into. The Trans Am sounded real good and seemed to drive well to the shop, which was only a three-mile ride. Not until we strapped it down on the dyno and started to take some readings would we know if we had a good candidate to extol the virtues of tuning for mpg.

Designing The Simulation

For our results to be credible, a repeatable and accurate test protocol would need to be developed. Actual on-the-road testing would not be an option since there would be too many variables present (wind, traffic, weather changes) and would not allow minor calibration changes to be monitored with accuracy. The use of RaceKrafter's Dynojet chassis dyno would then be the answer, but some modifications to the standard test procedure would be necessary.

The Dynojet is inertia based wherein the drive wheels of the car each turn a drum that weighs approximately 2,000 pounds apiece (a total weight of around 4,000 pounds). In normal practice, the dyno computer uses the rate of acceleration of the fixed mass (the drums) to determine the horsepower and torque at the tires. It is generally accepted that on a rear-drive car the power loss through the drivetrain is approximately 20 percent. Thus, if the drive wheel power is multiplied by 1.20, it will provide a good representation of the flywheel power.

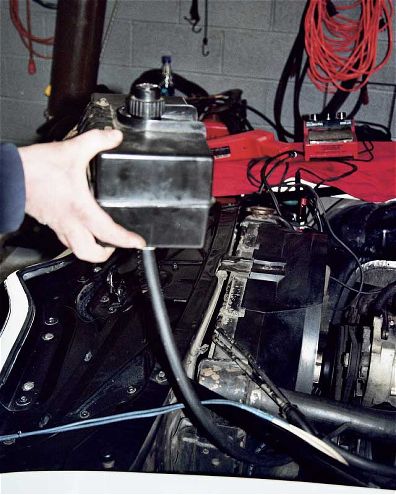

Our simple, remote fuel tank worked flawlessly throughout the test and sat on the fan shroud during each run. Since it was connected to the fuel pump, the height did not matter. It is being held up here for photography purposes.

Our simple, remote fuel tank worked flawlessly throughout the test and sat on the fan shroud during each run. Since it was connected to the fuel pump, the height did not matter. It is being held up here for photography purposes.

For our purposes, the dyno would be used to document horsepower and torque with the "as arrived" tune, and then after we dialed in the Poncho for fuel economy. The procedural difference would be during our testing. Dyno drums would be used to simulate our Pontiac going down the road while actually standing still. The federal government employs this style of test to determine EPA-rated fuel mileage and emissions output on new cars. This technique would not account for wind resistance, varied terrain, or anything else that could impact fuel consumption, either in a positive or negative manner. That will not be a concern since each test would be run exactly the same, which will make it accurate.

Since High Performance Pontiac didn't have access to a multimillion-dollar EPA laboratory, we had to evoke some good, old American ingenuity and develop our own test procedure. To this cause, the author thought up the idea of disabling the test car's fuel supply and replacing it with a much smaller remote tank. Then a measured amount of fuel could be added to the test tank and the vehicle driven on the dyno until it ran out of gas. If we measured the fuel accurately, then the test would be repeatable and thus valid.

A fuel tank with a shut-off valve from a discarded snow blower offered what we required and was obtained for free. Bob Wise disconnected the fuel line from the gas tank to the fuel pump and installed a line from the test tank to the fuel pump. This way, the Pontiac had no idea the factory fuel supply was disabled, and the gasoline would be pumped to the carburetor through its normal route. We had played with the idea of just gravity feeding the carburetor from the test tank, but the fuel pump line was so easy to access, and it would make the test more accurate.

Scott Roschel was responsible for "eyeballing" the fuel level on each run. By using only one person, we kept the fill rate accurate. It was also confirmed by a scale reading. Roschel was working on another project and was called away each time we needed fuel. That is why his hands are dirty.

Scott Roschel was responsible for "eyeballing" the fuel level on each run. By using only one person, we kept the fill rate accurate. It was also confirmed by a scale reading. Roschel was working on another project and was called away each time we needed fuel. That is why his hands are dirty.

A graduated two-quart plastic container with a pour spout from the housewares department of Wal-Mart was all that was required for a measuring device. One quart was measured, and a mark was made on the container to remove any error in one direction or another. To quality control our test to the highest standard, we weighed the container on a postal scale with one quart of gasoline. This way we knew on each test run the exact same amount of fuel would be supplied though visual and weight confirmation.

Since RaceKrafters had the postal scale, our low-tech-but-accurate fuel metering device cost us $1.59 for the container and about $1.00 for a piece of fuel line. So, for less than three bucks, we were in business.

A good thing about mathematics and accurate test protocol is the results can be expanded or shrunk to any standard you desire. We chose one quart of gasoline since it would allow quick test sessions, and we were looking to quantify a change in an A-B comparison. There was no need to run a gallon of fuel through the motor each time. Multiplying by four (four quarts to a gallon) we would accurately have a mile-per-gallon figure. We used the odometer in the car for distance traveled, and once again the amount of error was irrelevant since it would be fixed throughout the entire test.

Our procedure was to run the engine out of fuel, fill the test tank with one quart of gasoline, and then start the car and gently accelerate to 65 mph. This speed would be maintained until the engine ran out of gasoline. We would allow the dyno to coast until a speed of 20 mph was reached, and then the brakes would be applied and the odometer read. These steps were followed explicitly for each test run.

Bob Wise kept a close eye on the dyno instrumentation and did an excellent job in repeating the load on the engine during each test.

Bob Wise kept a close eye on the dyno instrumentation and did an excellent job in repeating the load on the engine during each test.

Keep in mind our test cycle was not designed to produce the best possible mileage, but intrinsically would be very fuel hungry. We measured the distance traveled for every quart of fuel consumed. Any gain realized would most likely be even greater under steady state cruise conditions such as on the highway. Follow along as HPP lets the pictures tell the story.

Building For Efficiency

Though substantial gains in fuel economy can be realized with external tuning, in essence all that is being done is bringing the engine to its full design potential. No decrease in fuel consumption can occur beyond the inherent thermal efficiency of the original design. Gains beyond that can be huge, but they require a rethinking of the internal engine design, much as is commonly done to make a Pontiac go faster. But, instead, the edict will be mpg instead of mph.

Every internal combustion engine experiences three areas of loss in the potential energy (measured in British thermal units) from the fuel consumed. They are: pumping, frictional, and thermal losses. Even the most powerful Pontiac only uses about 25 percent of the fuel's energy to transmit power to the crankshaft. Approximately a 25 percent loss is assigned to each of the three areas. The easiest and most productive way to increase fuel economy in any engine is to increase the static compression ratio. A higher compression ratio directly impacts the thermodynamic efficiency of the engine, or in simpler terms, reduces the amount of fuel by mass to produce 1 hp.

That is one reason why diesel engines are more fuel efficient than gasoline--the high-compression ratio (22:1 on normally aspirated versions) improves the thermal efficiency. The second reason for a diesel's stingy reputation is the fuel has more Btu's of energy than gasoline.

A higher compression ratio does bring along the need for higher fuel octane, but through good engineering this requirement can also be kept under control. New technologies such as piston and combustion chamber thermal barrier coatings, along with advanced coolants such as the unique Evans NPG+, allow for a higher-than-thought-possible compression ratio with older cylinder head designs.

Another untapped area for decreased fuel consumption is camshaft phase and over-lap. Advanced placement when referenced from the intake lobe centerline will increase volumetric efficiency at small throttle openings and allow the engine to do more work on less fuel. Decreased overlap will limit high-rpm breathing, but will make the engine more fuel efficient at part throttle and light load.

What makes all of this fun for an engine guy like me? Fuel-economy gains are more challenging than going fast. It is an engineering exercise that uses all of the same logic as building a hot rod, only it redirects it to another cause. Who knows, maybe in the near future there will be a spin-off publication of HPP called HEP, or High Efficiency Pontiac. Stranger things have happened.--RTB