E-mail: HOTROD@primedia.com * Mail: HOT ROD PIT STOP, 6420 Wilshire Blvd., Los Angeles, CA 90048 * Fax: 323/782-2223 * Message Board: HOTROD.com

Problems are both a hot rodder's bane and joy: A bane because there's nothing worse than a last-minute headache preventing you from getting the car rolling down the road; a joy because there's nothing like that feeling of overcoming adversity. Pit Stop is here to give you a helping hand. Parts interchange, tuning, proper combo, or even theory-we'll answer all the tech questions we have room for. When e-mailing, don't forget to include "Pit Stop" in the subject line, as well as your real full name and hometown or military unit, base, or ship in the message. If you have quality digital photos of the car or problem, and if they're at least 300 dpi at 4x4 inches or larger in size (bigger is always better), send those in too.-Marlan Davis

Porting Pontiac Heads

I have a set of '69 Pontiac 400 heads, casting No. 46. I would like to try my hand at porting and polishing. I would like any information on how to do this and what tools are needed.Connie MullinsClintwood, VA

First, a word about factory Pontiac heads in general: Pontiac heads were originally designed to get heavy cars up and moving. As such, they emphasize low-end torque over top-end power. Pontiac port volumes are roughly equivalent to a 350 Chevy small-block, yet most Pontiac engines are at least 50 ci larger. When it comes to porting the factory Pontiac heads, H-O Enterprises' Ken Crocie, a recognized Pontiac expert, says "You can't make a Pontiac head big enough. You can make it wrong, but not too big."

Looking at your No. 46 heads specifically, these are high-compression heads used on 400ci two-barrel engines rated at 290 hp. Their biggest limiting factor are the small valves-1.96 inches on the intake side, 1.66 on the exhaust. After installing large 2.11/1.77 valves seated with a good three-angle valve job and full porting, they have the potential to flow right up there with similarly modified factory big-valve, four-barrel, open-chamber, D-exhaust-port heads. The particularly weak exhaust ports require porting throughout the runner length. Naturally you'll have to gasket-match the intakes and extensively port the bowls and short-turn-radius areas on both the intake and exhaust runners to improve flow and match the new, larger valves. Complete valve job and head-porting instructions, as well as full-scale porting templates, can be found in the Engine Design and Blueprint Assembly Manual, available from H-O Enterprises' (PN TD-02, $12.50). Make copies of the templates and use them as gauges, following the porting directions given in the manual. H-O's booklet also contains a bunch of other useful Pontiac info.

Unless you have access to professional-grade shop equipment, it's best to farm the valve job out to a competent shop. Just tell them to do the valve job as specified in H-O's manual, not a typical generic Chevy job. Because your particular heads must be reworked to accept bigger valves, I recommend two separate trips to the valve-job shop: First, the shop needs to rough-in the seats for the larger valves. With the new seats established, take the heads back home to port them, enlarging the bowl diameter to the new seats and performing the other port mods per the H-O manual. Then return the heads to get the final valve-job done. Doing it this way avoids the chance of nicking the final valve-job during the porting process (likely if you're a first-timer).

Don't forget that most Pontiac engines have nonadjustable valvetrains. The factory used different-length valves to correct geometry problems. When upgrading small-valve No. 46 heads to larger valves, it is important to procure valves of approximately the same length as the originals. Alternatively, you can easily convert to an adjustable valvetrain using H-O Enterprises' SK-71 kit, which includes spacer washers and adjustable locknuts that work with your existing positive-stop rocker studs, rocker-arm balls, and rocker arms. The adjustable conversion option may be the best choice because you'll almost certainly want to run a big cam with the ported heads.

As for porting tools, a powerful, high-speed grinder is a must. Inexpensive air-powered die-grinders are available from a variety of sources, such as Harbor Freight-but of course a decent air compressor is needed to power it. Modern high-quality electric-powered die-grinders, such as those from Sears Craftsman, are a viable alternative, and a good one is more powerful than a cheapie air grinder.

Also required is an assortment of mandrels, carbide-steel grinding burrs, and various abrasive stones and flat grinding discs. Complete kits with an assortment of carbide burrs and abrasive rolls are available from Mondello Performance or Standard Abrasives. Use the carbide burrs for major material removal; the stones and rolls are suitable for final cleanup and polishing. Different flute angles on the steel burrs are needed for aluminum compared to cast-iron (aluminum requires a wider flute angle). Usually no lubricant is required with iron, but aluminum-head porting applications demand a special lubricant that prevents particles from clogging up the carbides and stones. Long-shank burrs are needed to reach deep inside the ports, but that in turn requires the ability to control the tool's motor speed to avoid twisting the long shank, so you should add an inline rheostat or power-control unit if your electric grinder lacks adjustable motor-speed controls. Ideally, this unit should have a feedback loop designed to keep the power up even as its rotational speed is reduced. Newark Electronics is one source for such sophisticated units, or you might try a good welding supplies dealer.

Where Do I Get . . ....weights and dimensions for American-made V-8 engines?W. W. BurlewSavona, NY

For classic U.S. engines in general, surf to carnut.com/specs/engdim.html. For Ford-only engine specs, go to: fordracingparts.com/download/charts/151.pdf. GM LS1/LS6 engine vital stats are available at: z06vette.com/forums/archive/index.php/t-75982.html.

...a small-diameter, deep-groove pulley for my Chevrolet alternator? I have problems throwing my long V-belt with the 5-inch-od aftermarket pulley I'm running now.Paul DyerSan Angelo, TX

A 351/48-inch-od deep-groove pulley is still available from your GM dealer under PN 3829387. March Performance (Westland, MI; 734/729-9079 or 888/729-9070; www.marchperf.com) sells a 2111/416-inch-od deep-groove pulley under PN 137. If the problem persists, you may need to fabricate a belt guide.

.. tools to check bellhousing face and bore runout?Patrick TyrrellWhite Hall, MD

A bellhousing indexing fixture and 1-inch-od dial indicator are available from Precision Measurement Supply (San Antonio, TX; 210/ 681-2405; www.precisionmeasure.com)

....a stroker kit for a '77 Olds 350?Michael BridgesMachesney Park, IL

Mondello Performance Products (Paso Robles, CA; www.mondellotwister.com; 805/ 237-8808) has 11/42-inch stroker kits in your choice of 9-12.0:1 compression ratios. You'll need to notch the cylinder-bore bottoms for clearance.

...a Web address or phone number for Legendary Auto Interiors?Dan JohansenBrookings, SD

Right here: Legendary Auto Interiors (Newark, NY; 800/363-8804; www.legendaryautointeriors.com).

...a set of full-length headers for a '95Impala SS?Dave ZajacBrighton, MI

Shorties, mid-length, and full-length headers for '92-'96 Gen II small-block-powered B-bodies (includes your SS) are sold by Clear Image Automotive (Auburn, WA; 253/852-1563; www.clearimageautomotive.com). Its "Quad-1" is the full-length configuration.

Nitrous And Propane

It seems to me that a nitrous oxide/propane combination could solve a lot of problems typically experienced on a nitrous/gasoline system, such as fuel-lag and detonation. I have a chemist friend who tells me that the stoichiometric ratio of nitrous to propane is about 5:1. I'd like to try this combination. Any suggestions or thoughts?Les KingTehachapi, CA

Propane solves some problems but creates others. I talked to several experts in the field, including Mike Wood of Nitrous Express; Mike Thermos of Nitrous Supply; Darrin Stettner, crewchief on Glen Sali's Pro Mod '91 IROC Camaro that ran 7-second, 198-mph e.t.'s. in 1998 using propane and nitrous; and David Vizard, automotive freelancer writer and director of applied performance sciences, University of North Carolina at Charlotte.

Propane has a high 104 octane rating. Extremely fast-burning, propane's efficient, complete burn keeps CO and unburned hydrocarbon emissions down at the expense (because of its very efficiency) of somewhat higher NOx pollutants. As injected into the intake manifold, propane is already in a gaseous state and completely atomized, so there is no distribution problem compared to liquid gasoline, which mostly doesn't vaporize until it enters the combustion chamber.

Propane yields excellent BSFC (brake specific fuel consumption) numbers, which are usually considered an important measure of an engine's efficiency. But curiously, even with good BSFC numbers, the same engine will see as much as a 30 percent drop in volumetric efficiency (VE) when the fuel is switched from gasoline to propane. According to Vizard, this is because gaseous propane takes up more space in the inlet manifold compared to a liquid fuel like gasoline.

When a chemical substance changes state from a liquid to a gas, it sheds heat (known as the "latent heat of evaporation"). A cooler mixture not only is denser (which makes for more power potential), it is also more detonation-resistant. The cooling effects of nitrous oxide as it changes state from a liquid to a gas when released from the nozzle into the intake tract are well-known and considerable. It is one reason you can get away with injecting nitrous with all of its extra energy potential. But don't forget that liquid gasoline also is undergoing vaporization, primarily in the combustion chamber, giving up some latent heat just when it's needed most to keep valve, piston ring-land, and spark-plug electrode temperatures under control. This benefit does not exist with propane, which is already a gas and nearly 100 percent vaporized before and after its injection into the engine.

On the other hand, depending on the amount of power-adder and its intended usage, there can be such a thing as too much cooling. Nitrous cools the incoming air/gasoline mixture so much that some of the heavier molecular chains in the gasoline brew have difficulty vaporizing. That's not good: At least 15 percent of the fuel must already be vaporized at intake valve closure to initiate effective combustion. This can be a problem on gasoline-fueled street cars running moderate levels of power-adder where driveability remains a concern. For cars running lots of nitrous, mixture cooling trumps vaporization concerns, especially if running race gas optimized for use with nitrous oxide.

As applied to propane/nitrous, there is a point where the danger from excessive heat outweighs propane's quick burn rate, high octane qualities, and good vaporization characteristics. On the street, where maybe you could easily run a 150-200hp nitrous kit on pump gas, with propane as both the primary fuel and the supplemental fuel, Vizard says to back this down to about the 75-100hp level. On the other hand, Stettner has run as much as a 250hp nitrous kit on street cars but cautions running that much nitrous with propane "is not for the general public. We start with a NitrousWorks kit but jetting is all trial and error."

By weight, Vizard says about 9.6 pounds of nitrous oxide are needed to combust 1 pound of gasoline. This compares to about 10 pounds of nitrous for each pound of propane. However, propane pressure at the injection nozzle is much greater than any gasoline system, and the propane is already vaporized. Theoretically, this means only slightly larger propane jets should be needed. To be on the safe side, Stettner recommends starting with propane jets that are about eight sizes bigger than the equivalent gasoline jet. On propane, the spark plug center electrode should turn white at the tip if the ratio is correct. "You can't really read propane," Stettner says. "An over-fat mixture will turn black."

A mild propane/nitrous system for street use is extremely driveable and smooth running. Even at 75 hp, when triggered Vizard says the "power hits like it was attached to your finger." This is probably because nitrous and propane have similar metering characteristics, with both under much higher pressure than gasoline (150 psi for propane; 750 psi for nitrous oxide).

These are nominal pressures and will vary by temperature-the lower the temperature, the lower the pressure. This keeps any established nitrous/propane flow ratios nearly the same under temperature fluctuations. By contrast, liquid gasoline's flow characteristics remain nearly constant under decreasing temperature conditions; any temperature drop alters the gasoline/nitrous pressure ratio, in turn causing air/fuel ratio fluctuations that create an over-rich condition when it gets cold (that's why most nitrous racers use bottle-warmers).

As for system layout, you can inject propane and nitrous with a plate under the propane carb (or fuel mixer). For seal compatibility and flow capacity, use an additional nitrous solenoid and Teflon-core braided-steel hose on the propane side in place of the normal gasoline solenoid and rubber-core braided hose.

Although big power-adder numbers on propane aren't practical using propane as both a primary and supplemental fuel, things get real interesting on hybrid fuel setups. According to Vizard, if you used propane as the supplemental fuel and good race gasoline as the primary fuel, each would tend to make up for the deficiencies of the other. There would still be latent chamber cooling from gasoline, but the propane would provide superior vaporization. Vizard says that "a propane/gas/nitrous motor with the right cylinder heads, cam, and compression ratio could put out way better than 3,000 hp" However, the Sali/Stettner car did it the opposite way, running propane as the primary fuel, and injecting VP C-16 race gasoline along with the nitrous. Stettner thinks this is the best way to go on a high-end system, since the bulk of the fuel is supplied at a pressure more equal to nitrous, yet injecting gasoline as the secondary fuel sufficiently cures any detonation tendencies.

Blown Chevy Small-Block Combo Query

My 300-miles-a-week daily-driven 350-powered '93 Chevy pickup passed the smog test with this combination: Edelbrock Performer heads (PN 6085, [sic]), Erson cam (PN E111021, 214/226-degrees 0.050-inch tappet-lift duration, 114-degree LDA), Edelbrock TBI intake, 590-cfm throttle-body with 68 lb/hr injectors, Vortech V-1 supercharger, 8-psi boost with supplemental fuel system, Crane HI-6 ignition with LX-92 coil and TRC-2 controller, set for on-demand at 4-psi boost, Edelbrock shorty headers into a single 3-inch exhaust with a 3-inch high-flow converter and MagnaFlow muffler, and a static [sic] compression of 150 psi (which I'm told is a 9.0:1 motor).

If I rebuild i using a GM Performance Parts ZZ4 short-block except for opening up the combustion chambers to get an 8.0-8.5:1 motor, I could add timing, but would this offset the reduction in compression? The other combination I am considering is the GMPP 383 with my current heads, naturally aspirated with port-injection. Would this be comparable to the supercharged ZZ4 for horsepower and torque?Doug EbbeckeLake Forest, CA

First, you're confusing static compression with cranking-compression gauge readings. While 150 psi should be acceptable, there is no correlation between that number and the engine's static compression ratio. Second, "PN 6085" doesn't exist in Edelbrock's head-numbering system. You probably have the Performer Centerbolt heads, PN 60859. These have 60cc chambers. GM's complete ZZ4 350 crate engine has a nominal 10.0:1 compression-ratio with its as-delivered 58cc heads and 0.051-inch-compressed-thickness head gaskets. All else remaining the same, you'd have to open up the Edelbrock chambers about 8 cc (from 60 to 68 cc) to get down to the 9.0:1 range. You'd have to make the chambers 15 cc larger to get down to about 8.5:1. Goodbye quench.

At any rate, if timing must be severely retarded with 8-psi boost at 9.0:1 to prevent engine knock, it makes sense to roll back the compression ratio to allow maintaining existing boost levels with a decent advance curve. Under this circumstance, adding ignition lead outweighs the compression drop. Note however that on a street car running pump gas, around 9.0:1 with 6-8 psi of boost usually is the best compromise in terms of overall driveability. The exact timing to run depends on air temperature and fuel quality. Ideally, you should have the computer pull timing out of the car as air temperature rises and you get into boost-or run an intercooler. Then you could have it all: compression, timing, and boost.

What about building a normally aspirated 383? According to forced-induction expert Ken Duttweiler, expect the additional 30-odd cubic inches to translate into a 40-lb-ft torque gain over an equivalent normally aspirated 350. Yet running just 6.5-psi of boost on the same 350 is worth about 115 lb-ft. There ain't no replacement for displacement-except forced induction! Why not put that 383 in there and supercharge it?

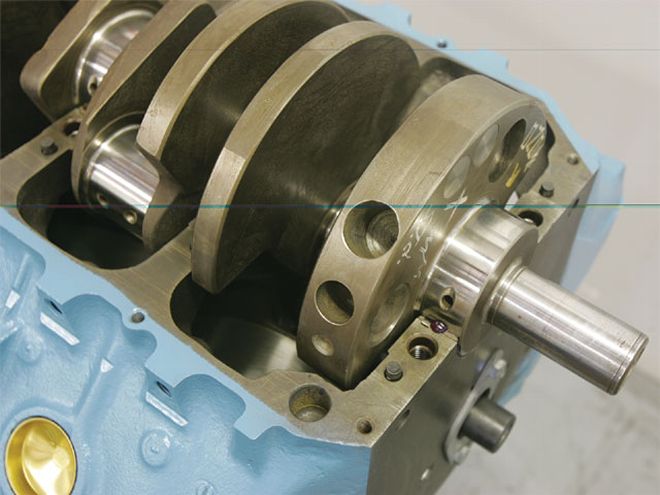

455 Crank in 400

Why is there such a difference between a 400ci Pontiac and a 455, power-wise? Better yet, why is there such a difference between a 400 Pontiac and a 400 Chevy small-block? By the way, in the 455 Pontiac dream engine story ("Pump-Gas Poncho," Jan. '05), one thing not mentioned was that a 455 crank turned down will not just drop right in a 400 block. I did this years ago and had to weld the crank's thrust-bearing area and regrind it to move it-then it dropped in the 400 block.Garret McCormickPigeon, MI

You're right-the Pontiac large-journal crank's thrust flange requires a fairly sophisticated welding technique to fit the small-journal 400 block. For most, this is something best left to an experienced performance engine builder.

Whether it's really worth the trouble to modify a 455 crank to fit into a 400 block is questionable in my opinion (other than the fact 455 blocks are getting scarce). Adherents of this procedure claim that the smaller 400 main-bearing size reduces friction, thereby minimizing parasitic losses inside the engine, but research has established that the pistons and rings account for about 31/44 of the mechanical friction in an average engine. The bearings and valvetrain are only responsible for the remaining 25 percent. Therefore-particularly on a budget engine rather than an all-out professional job-any effort aimed at reducing frictional losses would see the most gains by improving piston and ring design rather than worrying about bearing speed, particularly on a street-driven engine.

As for your questions, the 455 Pontiac makes more power than a 400 because it has 55 more cubic inches! On otherwise similarly configured motors, the larger-displacement engine should make more torque and power up to the point it becomes cylinder-head limited. When you compare the power differences of a 400 small-block Chevy with a 400 Pontiac, there's a huge difference between the as-produced versions and today's hot-rodded descendants. Originally, all 400 Chevys were plain-Jane two-barrel bread-and-butter engines. They were induction, cylinder head, and camshaft-limited. Any four-barrel Pontiac 400 (never mind the hi-perf Ram Air III and IV mills) would run rings around a stock 400 Chevy.

Fast-forward to today, and the outcome totally reverses itself: A good built 400 Chevy trumps a 400 Pontiac, mainly because cylinder head technology for the Chevy has continued to evolve, while the Pontiac's has pretty much stagnated. The most popular aluminum aftermarket Pontiac cylinder head flows about the same as a 20-year-old cast-iron Chevy small-block Bow Tie cylinder-head. Today we have raised-port Chevy heads, rolled-over Chevy heads, SB-2 heads, even splay-valve heads. Slap on a pair of these modern cylinder heads, choose a cam that matches their flow characteristics, improve the Chevy's bottom-end with long rods and lightweight pistons, and it's no contest (believe me, I like Pontiacs-if only someone would come out with a "clean sheet of paper" cylinder-head design, then Pontiac might have its revenge).