To take advantage of the large-bore engine, nothing but the best will do to allow this monster to breathe.

Last month we detailed the metamorphosis of a 346ci aluminum LS1 short-block into a 455ci beast. To recap, Motorsport Technologies of Houston, Texas, bored out the stock block and installed Darton liners that allowed the bore to be taken all the way out to 4.160 inches. Combine this with a custom-made Lunati forged-steel crank with a 4.185 stroke and you have the recipe for a stout 455 combo.

The stock LS1 cylinder heads fitted on the '04 GTO were good for a factory head. After all, not many factory cylinder heads can claim they can flow 233 cfm on the intake and 180 cfm on the exhaust at 0.600 inch lift at 28 inches test pressure.

For comparison purposes, the stock '70 No. 64 Pontiac 455 D-port cylinder heads flow 202 cfm on the intake and 175 cfm on the exhaust under the same testing conditions, and the famed 455 round-port H.O. 7F6 heads flow 231 cfm intake and 188 cfm exhaust. Having established what a factory wonder the LS1 heads are, neither they nor the vaunted LS6 cylinder heads flow enough to support the goal of 600 flywheel horsepower.

Jayson Cohen of MTI pulled out all the stops and had Robert Maenza, lead head porter and machinist, custom port a set of MTI Stage III-R cylinder heads. Beginning with a brand-new set of casting 243 LS6 heads, Robert will take us through the porting, assembly, and testing of these fire-breathing wonders.

From raw casting to the finished works of art, MTI invests more than 40 man-hours of labor to produce flow numbers of 336 cfm intake and 240 cfm exhaust at 0.650 inch lift. These impressive numbers are the result of the hand porting and larger 2.08/1.60 valves that are installed. The heads also receive heavier-duty springs and bronze valveguides. MTI's Stage III-R porting is available for your large-bore LS1; while the Stage II-E and R porting packages are perfectly mated to stock bore applications requiring 300-plus cfm on the intake.

According to Cohen, "Our goal was to run the maximum allowable compression ratio for the application without having to resort to racing gasoline or degrading the overall power of the package by pulling out timing to thwart detonation. Our Stage III-R cylinder heads bump the '04 GTO's compression from an actual 10:1 up to 11.25:1. The aluminum LS6 heads with their 64.5cc combustion chambers are a great basis for our heads."

"We don't CNC our cylinder heads," adds Maenza. "CNC'd heads have repeatable ports, but at MTI, we are continually improving our heads. Subtle porting changes such as bowl shape; short turn radius, or valve angles help us maximize short- and midrange flow and velocity, resulting in a better port. Intake and exhaust flow max numbers are often not the best indicators of power potential. A head that flows 300-plus cfm at 28 inches of mercury but has no low- to midrange flow or low velocity won't run as well as our heads."

Having established how robust the short-block is and the power potential of the Stage III-R heads, it was up to MTI to design the camshaft so that the GTO could be driven daily, pass emissions, and most importantly, create big power. Jayson went to the drawing board and designed a grind specifically for the large- bore GTO. Cut on a wide, 113-degree lobe separation angle and it features 228/232 degrees duration at 0.050 and 0.588/0.574 lift with 1.70 ratio rockers.

This cam would be considered marginally streetable on a 346-cubed application. Add cubic inches, and it's docile enough for daily driving without sacrificing that oh so important top-end pull. According to Cohen, "Camshaft selection was extremely important to the overall bal- ance of the package. The wrong cam could have killed the idle characteristics and made this as finicky as so many other overcammed Gen-III powerplants."

Follow along as we complete the engine build and test this powerhouse on the dyno.

On The Street

Our thanks to Burke Bradley, the owner of this sweet '04 RA7 GTO. As a practicing anesthesiologist at a major Houston-area hospital, he surely knows how to lay them down with the best of them. Bad pun, but then again, isn't it ironic that he chose natural aspiration over nitrous oxide for his personal ride?

Driving duties on this beautiful day in Houston were handled by Jayson Cohen. With more than a few quick rides under his belt, even rowing the GTO's gearbox was a breeze for him.

Upon entering the car and firing it up, one instantly knows there's power just waiting to be unleashed. The engine has a small, healthy lope to it and settles in between 900 and 1,000 rpm. You can hear the performance exhaust, but it could never be described as obnoxious. Cruising around like normal people on the roads of Houston wasn't much different than driving in any other Pontiac. There was no exhaust drone; the engine was crisp and idled great.

When the traffic cleared and Cohen dropped thehammer, our pedestrian ride turned into SuperGoat. Even with the sticky Michelin Pilots in the rear, the tires were a smoking blur. Starting out in First gear, Cohen got rubber in four gears before letting off. We aren't just talking about measly tire scratches here, but big, bad, ugly positraction black marks, even in Fourth. Putting the pedal to the floor planted me firmly to the back of the seat and held me there! There is 10-second power in the car, but keeping the tires from spinning is an entirely different subject. Suffice it to say this '04 GTO moves with rapid alacrity.

A funny thing happened shortly after we returned to the shop. One of Houston's finest was camped out a mere 50 feet down the road from the shop the rest of the afternoon. We guess he just wanted to get a glimpse of what modern MTI Pontiac power is all about. Hello, Officer Friendly! --R.A.

Cylinder-Head Flow Comparison

All flow numbers are quoted in cfm at 28 inches of test pressure. Gen-III cylinder heads were tested on MTI's SuperFlow SF600 flow bench. Traditional Pontiac cylinder heads are also quoted in cfm at 28 inches test pressure but on Butler Performance's SuperFlow SF600 flow bench (Butler Performance, (931) 762-4596, Butlerperformance.com).

Pontiac 7F6 heads are the ''72 round-port H.O. units. Butler Performance Edelbrock race port, shown for comparison purposes. Although this is a bit of an apples-versus-orange comparison, it points out that the stock LS6 castings (with some magic from MTI) rival what it took the aftermarket and talented porters to achieve over the years.

Valve SizesIntakeExhaustLS12.001.55LS62.001.55MTI Stage III-R2.081.60Pontiac 4552.111.77 JBP CNC Edelbrock2.111.77On The Dyno

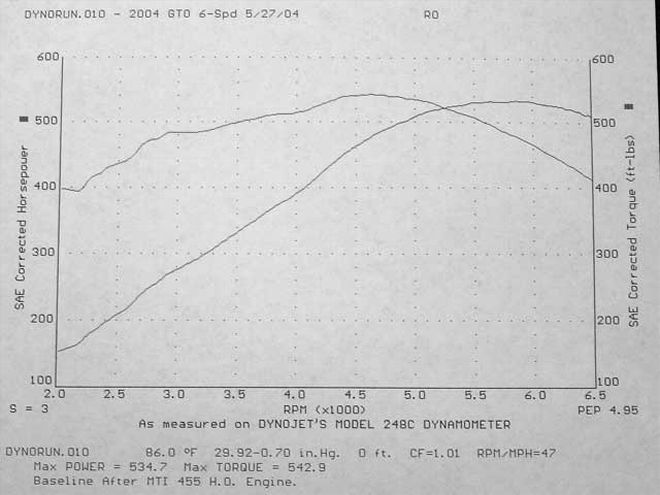

Testing of the '04 RA7 GTO was performed at MTI in Houston, Texas, on its Dynojet model 248C dyno that is capable of measuring up to 1,200-wheel horsepower. An in-car monitor is used to collect real-time air/fuel ratio (A/F) data. MTI has an extensive collection of Gen-III engine tunes, and Jayson Cohen began by choosing a custom tune from his library. After loading the base tune, the GTO required about three hours of driving, along with both part- and full-throttle dyno runs to dial in the computer program using LS1edit.

All testing was done in Fourth gear with the traction control off. Correction factors use a standardized SAE calculation, which include reference temperatures of 77 degrees F and a barometric pressure of 29.23 inches of mercury. Test parameters are: inlet air temperature 86.0 degrees F, barometric pressure 29.92, vapor pressure 0.70 Hg, correction factor 1.01.

Torque is the name of the game, and as you can see on the dyno chart, this big-bore engine has it in spades, without sacrificing power in the upper rpm range. Torque peaked at 542.9 lb-ft at 4,600 rpm and maintained a curve that Jayne Mansfield would be proud of. At 2,000 rpm, the engine put out 400 rear-wheel torque and exceeded 500 lb-ft from 3,500 rpm to 6,500 rpm.

Horsepower? Yes, this big-bore monster has that as well. How about a peak of 534.7 at 5,900 rpm! In addition, the engine carries more than 400 rear-wheel horsepower at 4,100 rpm and in excess of 500 rear-wheel horsepower from 4,900 rpm to the 6,500-rpm rev limit.

Mind you, this isn't flywheel horsepower, but rear-wheel horsepower. Extrapolate the peak numbers with a typical drivetrain loss of 15-20 percent and MTI's goal of 600 hp at the crank was met. Take a close look at the dyno chart and then picture how this powerplant would perform in your late-model GTO or Firebird. If this doesn't change your preconceptions of the LS1 and Gen-III families of engines, nothing will. Bore, stroke, and cylinder head characteristics define engine performance and torque, not the marque or date stamped on the block.