Roller rockers are not glorious parts. They look trick, but they live a pretty dismal life, working feverishly, always trying to keep things stable. Glory's one thing, but are they worth the cost? Heck yes, if they put up the numbers, and that's all that counts. We set out to prove it using a basically stock Chevy 350 with a Comp Cams XE 268H hydraulic cam, an Edelbrock Performer RPM intake, a 750-cfm Speed Demon carb, and a set of Trick Flow 23-degree heads. Roller rockers make power two ways. First, a rollerized rocker fulcrum reduces energy losses from mechanical friction in the drivetrain, freeing up horsepower. Second, a higher rocker-arm ratio effectively increases the camshaft's lift and duration by holding the valves open farther and longer, allowing more air to flow through the head ports without changing the cam.To put the theory into action, we had Westech Performance Group flow a set of Trick Flow 23-degree heads, which flowed 250 cfm at 0.500-inch valve lift on the intake port and 183 cfm at 0.500-inch lift on the exhaust side (see chart).

The XE 268H cam has 0.477/0.480-inch lift with 224/230-degrees duration at 0.050, so theoretically it would not open the valves high enough with 1.5:1 rockers to even reach peak flow through the runners. Stepping up to a higher rocker-arm ratio should therefore release quite a bit of pent-up power, at least until we exceeded the flow capabilities of the head. Before you decide to up the ante with a larger-ratio roller rocker, check for piston-to-valve clearance. The higher the ratio, the higher the valves are held open at the critical points in the firing cycle when they're near the tops of the pistons. You could have a problem if you're already close.

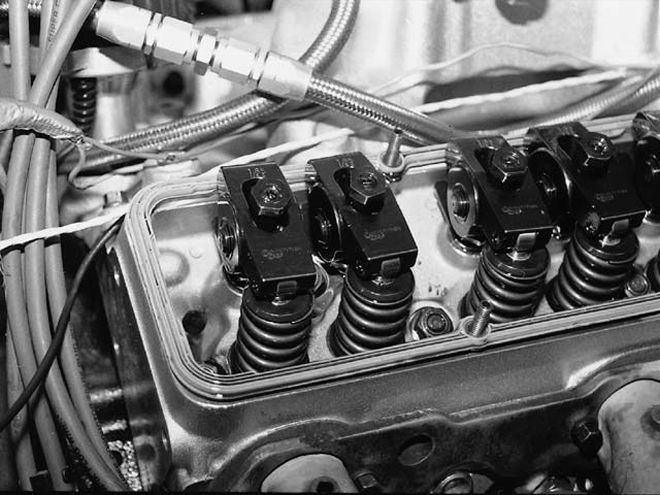

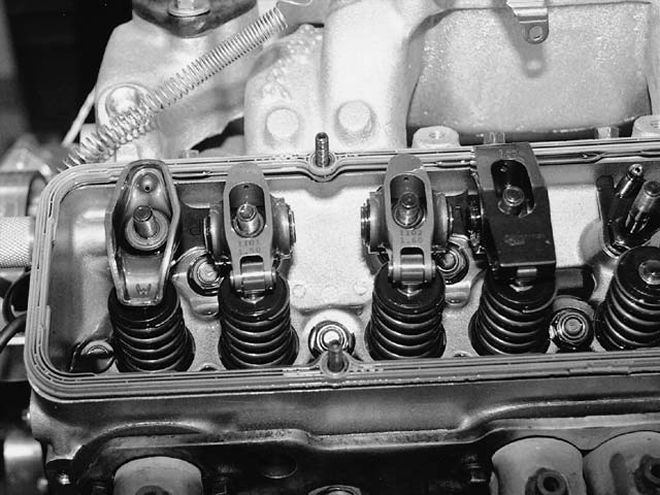

After our baseline pull with the stock rockers, we installed the Comp Cams 1.5 roller rockers. Notice the adjustable poly-lok and full roller tip on the No. 2 cylinder exhaust valve in comparison to the stockers. The 1.5 rockers are very similar to the 1.6 rockers except for a change in arm-throw ratio.

After our baseline pull with the stock rockers, we installed the Comp Cams 1.5 roller rockers. Notice the adjustable poly-lok and full roller tip on the No. 2 cylinder exhaust valve in comparison to the stockers. The 1.5 rockers are very similar to the 1.6 rockers except for a change in arm-throw ratio.

First we ran the motor with a set of stock 1.5:1 stamped rockers with pivot-ball fulcrums, and averaged 389.9 hp and 407 lb-ft of torque at 6,000 rpm. With the baseline laid down, we moved on to a set of Comp Cams 1.5:1 roller rockers. At the same 6,000-rpm peak, we made 401.1 hp and 412.9 lb-ft of torque, a gain of 11.2 hp and 5.9 lb-ft of torque.

Moving to the 1.6:1 rockers should show some gain considering the intake/exhaust lift numbers would be slightly larger; the cam's valve-lift specs would increase to 0.508/0.512-inch lift, right in the heart of the Trick Flow heads' peak-flow numbers (see the Math Anyone? sidebar). We were happy to see the average power levels increase again, this time by 12.5 hp and 9.9 lb-ft of torque.

For the final test, we pulled out the 1.65:1 rockers, which effectively increased max lift to a still-safe 0.524/ 0.528 inch at the peak. While power went up 0.4 hp and 1.5 lb-ft, the average didn't show any real gain by going from the 1.6:1 to the 1.65:1 rockers because we'd exceeded the ability of the heads to flow more air.

The Comp 1.65:1 High Energy rockers featured all-aluminum construction with a rollerized fulcrum. On our engine, the bigger ratio showed minimal gain over the 1.6:1 arms, but depending on the flow characteristics of your heads, results may vary.

The Comp 1.65:1 High Energy rockers featured all-aluminum construction with a rollerized fulcrum. On our engine, the bigger ratio showed minimal gain over the 1.6:1 arms, but depending on the flow characteristics of your heads, results may vary.

Overall, we gained 24.1 hp and 17.3 lb-ft of torque just by bolting on a set of rocker arms, which would make a noticeable difference at the track and in the seat of the pants. If you decide to venture from stock cast stampings to a full roller-rocker assembly, there are a couple things to remember. Again, check for piston-to-valve clearance, valvespring coil-bind, and retainer-to-valveguide interference. Also find out how much your current set of heads flow--if you're already maxing out the cylinder-head flow capabilities with a lot of cam, you won't see a gain like ours since you already have the additional lift in the lobes. Providing you can use the extra lift, higher-ratio roller rockers are more than worth their weight in aluminum.

Shown here from left to right are the three rocker-arm types we tested: a stock stamped 1.5:1 rocker, Comp Cams 1.5:1 Pro Magnum roller rocker, Comp Cams 1.6:1 Pro Magnum rocker, and a Comp 1.65:1 High Energy aluminum rocker.

Trick Flow23-Degree Head Flow FiguresValve LiftIntake Exhaust (inches)Port (CFM)Port (CFM)0.05032280.{{{100}}}65700.{{{200}}}1331020.{{{300}}}1881400.400226{{{164}}}0.5002501830.{{{600}}}251183

Range: 3,000-6,000 rpmTEST ARPMTorque (lb-ft)HPStock RockersAvg: 4,500386.8329.9Min: 3,000337.8214.5Max: 6,000407.0389.9TEST B1.5:1 Roller RockersAvg: 4,500393.4335.6Min: 3,000344.6220.6Max: 6,000412.9401.1TEST C1.6:1 Roller RockersAvg: 4,500401.9343.2Min: 3,000353.2223.6Max: 6,000422.8413.6 TEST D1.65:1 Aluminum Roller RockersAvg: 4,500402.4343.5Min: 3,000352.0225.0Max: 6,000424.3414.0

Shown here from left to right are the three rocker-arm types we tested: a stock stamped 1.5:1 rocker, Comp Cams 1.5:1 Pro Magnum roller rocker, Comp Cams 1.6:1 Pro Magnum rocker, and a Comp 1.65:1 High Energy aluminum rocker.

Trick Flow23-Degree Head Flow FiguresValve LiftIntake Exhaust (inches)Port (CFM)Port (CFM)0.05032280.{{{100}}}65700.{{{200}}}1331020.{{{300}}}1881400.400226{{{164}}}0.5002501830.{{{600}}}251183

Range: 3,000-6,000 rpmTEST ARPMTorque (lb-ft)HPStock RockersAvg: 4,500386.8329.9Min: 3,000337.8214.5Max: 6,000407.0389.9TEST B1.5:1 Roller RockersAvg: 4,500393.4335.6Min: 3,000344.6220.6Max: 6,000412.9401.1TEST C1.6:1 Roller RockersAvg: 4,500401.9343.2Min: 3,000353.2223.6Max: 6,000422.8413.6 TEST D1.65:1 Aluminum Roller RockersAvg: 4,500402.4343.5Min: 3,000352.0225.0Max: 6,000424.3414.0

Fast Facts

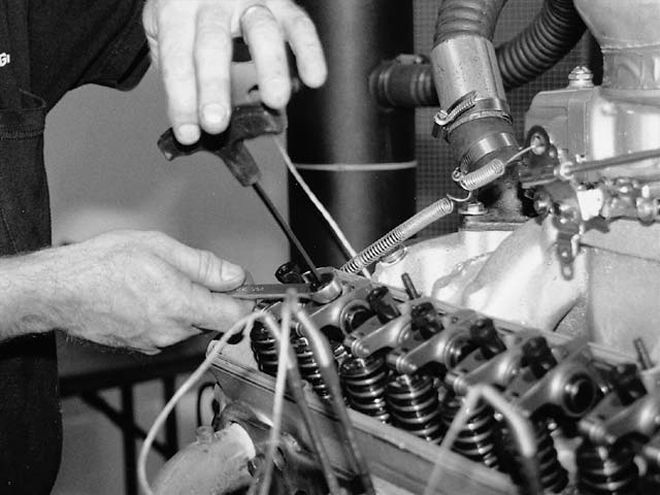

We prefer to adjust the rockers in the firing order of the motor using the Exhaust Opening, Intake Closing method (use EOIC as a shorthand memory aid). This method ensures that the lifter of the valve you're adjusting is on the basecircle of the cam when you set the lash. To begin, put all the rockers in place and tighten the nuts or Poly-Loks enough that the arms will open and close the valves as the motor is being turned over. Start with the No. 1 cylinder intake valve and turn the motor until the exhaust valve is just beginning to open. The intake rocker should be loose; if not, loosen the nut until you can move the arm. Make sure the pushrod is seated in its pocket on the arm and tighten down the nut slowly until you can no longer move the arm or turn the push rod. This is zero-lash. Tighten the nut 1/8- to 1/4-turn more, then tighten both the nut and poly-lock with an Allen wrench another 1/8- to 1/4-turn at the same time. Do this to all the intake side rockers. To adjust the exhaust sides, again go in the firing order, but allow the intake valves to close 1/2 to 3/4 of the way before you adjust the exhaust valve.

Math Anyone?

If you're not sure what the valve-lift numbers will be with a larger-ratio roller rocker, then get out the calculator as we fill you in. Take the intake/exhaust lift numbers from the cam catalog and choose one side to begin with. For example, the Comp Xtreme Energy 268H has 0.477-inch lift at the valve on the intake side. Since the 350 comes with a factory 1.5:1 ratio rocker arm, we take 0.477 and divide it by 1.5. This results in 0.318 inch, which is our lobe lift on the intake side. Next, take 0.318 and multiply it by the new arm ratio. With a 1.6:1 rocker, this gives us 0.508-inch valve lift at max lift, an increase of 0.031 inch. It doesn't sound like much, yet it was enough to show a sizeable gain, mainly because it increases the amount of time that the valves are open at higher lifts, allowing more air to flow through the heads. The valve will now see 0.500-inch lift twice during each combustion cycle (once as it opens and again after peak lift on the closing side). Do the same for the exhaust side and be sure to check for piston to valve clearance before making any radical change.