NASCAR technology for the street sounds counterintuitive, but in reality the realm of ultimate pushrod race engines holds the secret to rejuvenating one of the best head designs ever created for the small-block Ford: the Cleveland. That’s because prior to the release of Ford Racing’s magnificent clean-sheet FR9 race engine in 2009, Ford’s NASCAR program had overt muscle car roots. For the three decades preceding the FR9, the engines powering every Blue Oval racer were essentially 351 Windsor blocks topped with 351 Cleveland-derived heads.

Thirty-plus years is an extraordinarily long time to go between racing engine changes for a manufacturer, but you know what that gets ya? A lot of time sorting out and fine-tuning to create fully optimized engines. For example Carl Edwards, driver of the No. 99 Ford for Roush Fenway, finished the 2008 season with a series-high nine victories. Not too bad for a platform considered archaic by NASCAR standards.

That extended life also brought forth dramatically revised and near perfected versions of the original Cleveland heads, thanks to the efforts of Ford Racing, Roush Racing, and Robert Yates. The A351, B351, C302, C302B, C3, C3H, SC1 (Sprint Car 1), and finally the most radical, the D3. That last head was worked so well that it was used right until the FR9 bowed. Even cooler is the fact that all of them will technically bolt right onto any Ford Windsor or Cleveland small-block.

When NASCAR banned the use of canted valves on cylinder heads (the Cleveland’s signature design) in 1990, Robert Yates stepped in to revise the C302 head. The intake valve cant was removed and the angle was altered, but the traditional stagger arrangement remained. The new heads colloquially became known as “Yates.” Notwithstanding, Ford used recycled part numbers on some of the intake manifolds so there are Yates and C302 intakes that carry the same part number. That did lead to a bit of an issue with identification among those seeking the ultimate heads for their small-block Fords, since the pre- and post-Yates heads were quite similar looking to the untrained eye.

Of course all of those iterations were very specific application race parts designed for ultrahigh rpm use and regular maintenance. What the Ford world really needed was a head that took all of those lessons learned from decades of NASCAR competition, and put them into a street-friendly head—one that makes massive power, of course.

That’s where Troy Bowen at Ford Performance Solutions (FPS) saw a gap. There were updated Cleveland-style heads on the market, and Cleveland-headed Windsors are nothing new, but he felt there was power left on the table. His first iteration, known as the Avenger XTC 351, worked well, but a newer version, dubbed the Avenger XTC-R, blends original Cleveland and the best bits of NASCAR design into a head. That brings everything full circle—street to race, and back to street. That’s perfect for a car like Max Effort that’s a little bit Pro Touring, a little bit road race, and touch of NASCAR thrown in for good measure.

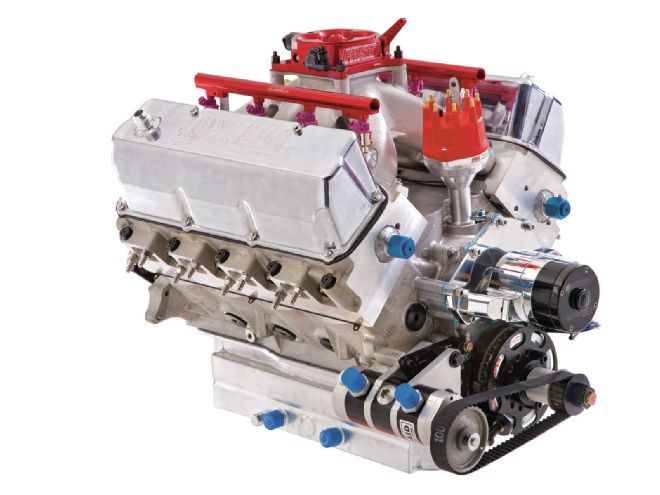

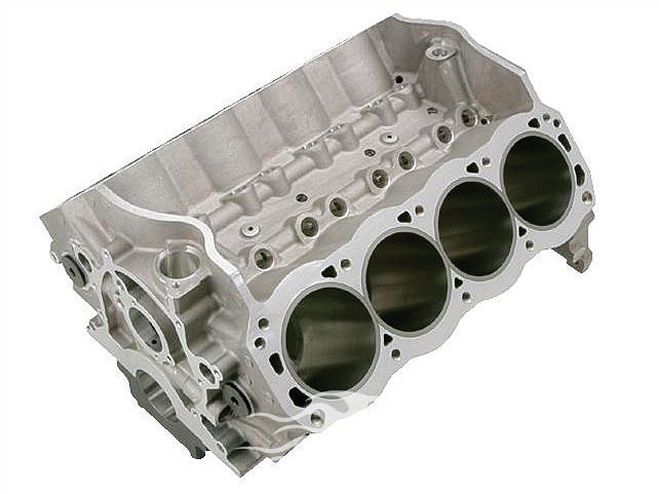

The foundation for Max Effort’s engine is Dart’s virgin 355-T61 aluminum block. The block uses scalloped outer water jacket walls to improve coolant flow around the cylinders to ward off detonation and promote consistent cylinder temperatures when run at extended high rpm. On top of that, the upgraded oiling system features a complete stock-type system, plus a low-restriction priority main oiling system with front and rear external oil pump feeds. Both of those benefits are especially important when on track. The block’s light weight will take important pounds off the nose to help make up for Max Effort’s heavy hideaway headlights.

The foundation for Max Effort’s engine is Dart’s virgin 355-T61 aluminum block. The block uses scalloped outer water jacket walls to improve coolant flow around the cylinders to ward off detonation and promote consistent cylinder temperatures when run at extended high rpm. On top of that, the upgraded oiling system features a complete stock-type system, plus a low-restriction priority main oiling system with front and rear external oil pump feeds. Both of those benefits are especially important when on track. The block’s light weight will take important pounds off the nose to help make up for Max Effort’s heavy hideaway headlights.

The craziest part of this build isn’t the awesome power production; it’s that this combination we threw together is designed to run on premium 91-octane pump gas. Read on to see how FPS makes it happen.

By the Numbers

438ci Ford

Block: Dart 9.5 deck Race Series aluminum Windsor

Crank: RPM-International

Rods: RPM-International

Pistons: Ross Racing

Rings: Akerly and Childs

Bearings: Clevite 77 from Summit Racing

Balancer: ATI Super Damper

Timing Set: COMP Cams

Oil pan: Aviaid dry-sump

Oil pump: Aviaid two-stage dry-sump, Petersen pulley

Cylinder heads: Ford Performance Solutions XTC-R 351

Rocker arms: T&D Machine shaft rockers, modified by Ford Performance Solutions

Intake: Edelbrock 2863 C3 NASCAR, ported and EFI’d by Ford Performance Solutions

Gaskets: Fel-Pro throughout, Fel-Pro PermaTorque MLS head gaskets

Bolts/studs: ARP throughout, ARP stainless bolt kit from Summit Racing

Cam: COMP Cams solid roller

Lifters: COMP Cams solid roller

Pushrods: COMP Cams

Distributor: MSD Pro-Billet

Plug wires: MSD Super Conductor

Valve covers: Ford Performance Solutions polished aluminum

On the Dyno

438ci Ford Small-Block

Snow Performance

Naturally Aspirated

RPM:

TQ:

HP:

TQ:

HP:

4,000

525

400

518

394

4,100

540

422

528

412

4.200

552

442

537

430

4,300

561

459

547

448

4,400

574

482

556

466

4,500

588

504

569

487

4,600

601

526

583

511

4,700

612

548

594

531

4,800

619

566

605

553

4,900

624

582

610

569

5,000

629

599

613

584

5,100

631

613

615

597

5,200

630

624

615

609

5,300

627

633

612

618

5,400

624

642

609

627

5,500

620

650

606

634

5,600

616

657

602

642

5,700

610

662

599

650

5,800

605

669

595

657

5,900

602

677

589

662

6,000

600

685

584

667

6,100

596

692

580

674

6,200

592

698

576

680

6,300

586

703

570

684

6,400

581

708

565

688

6,500

577

714

561

694

6,600

574

721

558

701

6,700

569

725

553

705

6,800

563

729

547

708

6,900

555

730

539

709

7,000

548

731

533

710