We've all heard the talk. It seems to run the gamut from, "Dude--headers are worth 100 hp," to the naysayers who snivel "Headers? They aren't worth the trouble." The truth is actually somewhere in the middle. Because results can vary so wildly, we decided to take a look at some past testing just to see what works and what doesn't.

If you're new to performance engines, and all headers tend to look alike to you, you might want to start with Jim McFarland's treatise on header design on page 62. This will give you the basics on why headers are designed the way they are, and why they don't all look the same. For this story, we're going to perform several header comparisons to shed some light on that age-old question of how much power headers are really worth.

All the dyno tests in this section were performed on different small-block Chevys, but when it comes to headers and exhaust tuning, this same information is completely relevant to any engine--only the header sizes change to match the displacements. This is a relatively busy subject with plenty of variables, but once you get to know all the important characters in this horsepower and torque stage play, the ending is always fairly predictable. Most of all, have fun with this. This is one session involving lots of hot air that's actually helpful.

Headers vs. Cast-Iron Exhaust

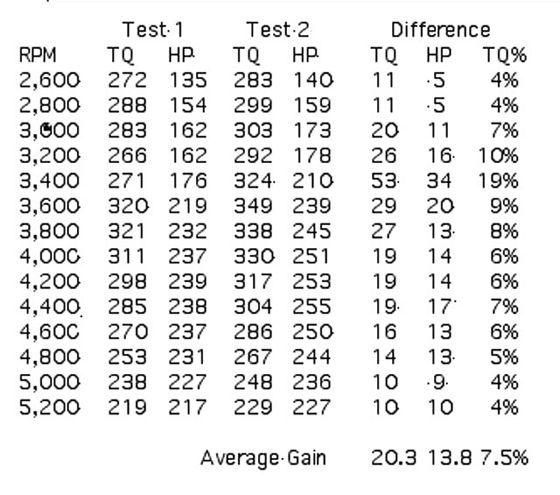

We'll start with a very mild Goodwrench 350ci small-block test with stock cam timing. The idea here is to compare the power output of a stock small-block 350 with cast-iron exhaust manifolds and headers. Because this is a mild engine, the peak power difference occurred relatively early in the power curve, with a maximum 34 hp and 53 lb-ft of torque gain at 3,400 rpm. That's an excellent 19 percent improvement in torque. Had the engine been fitted with a decent camshaft to allow the engine to make more power around 5,000 rpm, the improvement would have been even greater. However, this test does point out that even a stock engine will respond to a decent set of headers. As power potential increases with a good set of heads and a camshaft, headers and a free-flowing exhaust system become absolutely essential components.

Test 1: Stock GM Goodwrench 350 with Q-jet and aluminum intake, stock iron exhaust manifolds, a stock camshaft, and a 2 ½-inch exhaust system with turbo-style mufflers.

Test 2: The only addition is a set of 1 5/8-inch Hooker street headers with the same exhaust system.

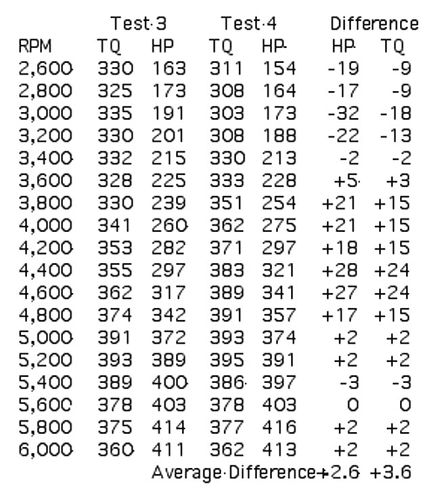

Looking for a Header? Tri-Ys

The book on Tri-Y headers is that they pump up the midrange torque over a set of four-into-one headers, which is exactly what we saw with this test. In the midrange between 3,600 and 5,200 rpm, the torque jumped as much as 27 lb-ft, but this comes at a price. Note that the average torque gain throughout the entire curve is only a scant 2.6 lb-ft. This is because at the lower engine speeds like 3,000 rpm, the Tri-Ys lost 32 lb-ft compared to the four-into-one header. Would these Tri-Ys be quicker in a mild street car? When we plugged the two power curves into the Racing Systems Analysis Quarter Pro simulation, the two curves produced very similar results. The four-tube-header version ran a scant 0.08-second and 1.1-mph quicker through the quarter than the Tri-Ys. Much of the difference was due to the slower 60-foot time exhibited by the Tri-Ys because of the torque loss below 3,400 rpm. The simulation used a 2,600-stall converter. It's possible that with a little carburetor work, that torque loss could be overcome. The Tri-Ys might have over-scavenged the engine at low rpm, requiring more fuel, and that could make these two headers more even in the car. But there appears to be no significant gain in performance with the Tri-Ys. It's mostly about where you want the torque gain to occur within the engine's power curve.

Test 3: Four-into-one 1 5/8-inch headers on a mild 355ci small-block with an Edelbrock RPM dual-plane intake.

Test 4: Same as above, except we added a set of Doug Thorley Tri-Y headers.

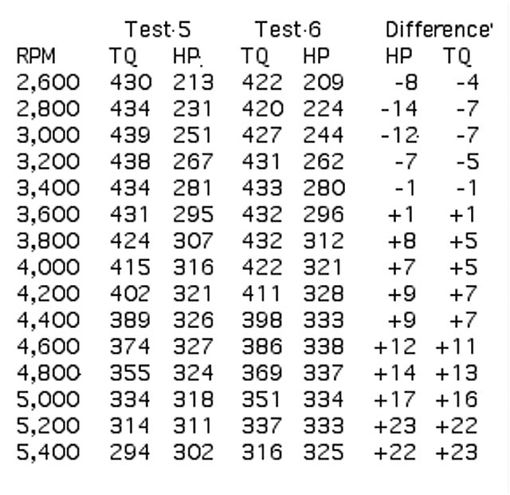

The Long and the Short of It

This is an interesting test of header length. Test 5 compares standard-length 15/8-inch headers to Test 6 with the same diameter but shorter-length intermediate headers. By looking at the Difference column, you can see that the shorter headers sacrificed torque below 3,600 rpm but made up for that by making as much as 23 more horsepower at the top. The average torque made by both engines is within 1 lb-ft, which is negligible. Basically, the shorter headers moved the torque higher up the rpm curve. If you plugged the intermediate-length header curve into a light car like an early Mustang or early Chevy II, for example, where you could not use a large tire, then the shorter headers might make traction a little easier to achieve. But you'd want to use the long-tube headers in a big, heavy vehicle or a truck where the stronger torque curve would help acceleration.

Test 5: A mild 355ci small-block with Hedman 1 5/8-inch, 34-inch long-tube headers with a 2 ½-inch exhaust system and a pair of Flowmaster mufflers.

Test 6: Same as above except with a set of Hedman 1 5/8-inch intermediate-length headers.

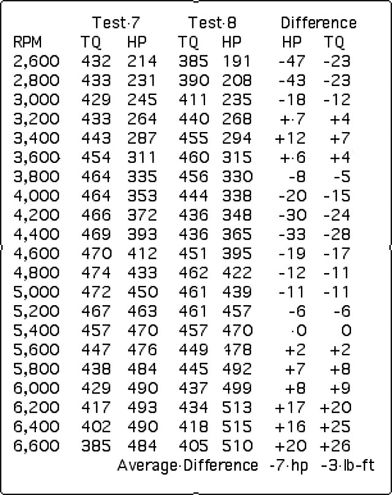

The Big Tube Test

This is a great example of how larger headers affect the power curve. The larger 1 7/8-inch headers lost a tremendous 47 lb-ft of torque at the bottom of the curve. By 3,400 rpm, the big headers were actually making a little more than the smaller 1 5/8-inch headers. This may be a hiccup with the smaller header power curve that could be addressed with jetting or timing had we spent more time on tuning. By 4,400 rpm, the smaller headers were making as much as 33 lb-ft more torque than the larger headers. Then by 5,600 up through 6,600, the larger headers took over and made as much as 26 more horsepower at 6,600 rpm.

If you look at the average power curve numbers, you can see that the larger headers actually made slightly less average power. That's because the horsepower gain at the top did not completely make up for the torque loss at the bottom of the curve. So what's the bottom line here? If this engine is going into a light car with a manual trans and a deep rear gear, or at least an automatic with a stall speed of no less than 3,600 rpm, the larger headers might be a slight advantage. The important point here is that a 13/4-inch header is probably the answer, since it would improve the low-speed power while not sacrificing nearly as much horsepower at the top end.

Another point worth mentioning is that what we're seeing here with these two primary-pipe-diameter power curves is not really as much about power loss or gains as it is about moving the curve around where the engine makes its best power. Had we tested a set of 1 ¾-inch headers, we're confident we would have witnessed an average power increase over the other two primary pipe diameters. This merely reinforces the idea that engines operate best when outfitted with the right set of parts that complement the rest of the engine package.

Test 7: A 406ci small-block Chevy outfitted with a set of Dart Pro 1 heads, a healthy mechanical-roller camshaft, a set of Hedman 1 5/8-inch-diameter primary-pipe four-into-one headers, and a 2 ½-inch exhaust using a pair of Borla XR-1 mufflers.

Test 8: The same engine outfitted with a set of Hedman 1 7/8-inch-diameter primary-pipe four-into-one headers with the same Borla exhaust system.