Once upon a time, we dropped a budget-built 360 in a '74 Challenger and ran 12s on the cheap, but that was over 15 years ago when a 12-second e.t. was quick and respectable. Times have changed. Your ride needs over 500 hp and better run 11s or faster to be competitive with today's classic and/or modern muscle cars. Nowadays, if you want a small-block that's a strong street driver, a stroker is the way to go. Most know that a stroker engine will deliver additional bottom and mid-range torque, making street driving a more pleasurable experience.

The stroked 340 small-block that's the subject of this story will be implanted into the Slick Challenger you've been following the last few issues. We've refinished its tail end ("Getting Some Tail," June '14), installed a new fuel system ("Slick, Stealth Fuel System," September '14), refreshed its mice-infested interior ("Clean, Quiet and Cool," Oc. ‘14) and upgraded/replaced the clutch and transmission linkage components ("Clutch and Trans Connection," Dec. '14). If you missed those stories, our project car is a 1973 Dodge Challenger Rallye 340 with factory air conditioning and the gear-grabbin' Pistol Grip four-speed. The plan back in '99 was to build a 360 to replace the original 340, which had spun a rod bearing and wiped out the cam/lifters back in '88. Plans changed and were put off a few times. Unfortunately, the previous owner, Slick, died in 2008. This resurrection/buildup of the Slick Challenger will be dedicated to the memory of its late owner, and instead of a 360, we're building a 416-inch stroker based off a 340 block.

Times have changed. Your ride needs over 500 horsepower and better run 11s or faster to be competitive with today's classic…

We picked up a standard bore 340 over 10 years ago for a '73 Challenger Rallye 340 project, which had belonged to a good friend who's since passed away. The clean E-Body was sitting in his home garage wounded with a spun rod bearing and wiped cam lobes for over 25 years. My goal was to bring it back to life.

The Scat Crankshafts 340/416 rotating assembly (PN 1-48013BI) was a sight for sore eyes! All the rotating/reciprocating parts (forged 4340 steel crank with a 4.000-inch stroke, 4340 I-beam rods, forged aluminum pistons, chrome-moly rings, main and rod bearings) are fully inspected to ensure quality and balanced in-house by Scat. This high-quality rotating assembly is rated for up to 800 hp. Another stroker kit we considered from Scat for the 340 is a 372ci rotating assembly using a 3.580-inch stroke crank, but we wanted maximum cubes.

We brought the 340 block to IDM Speed and Machine in Stafford Township, New Jersey (609-978-6411). Our LA block went through three Amp Pro machines for a thorough cleaning before Magnaflux and machine work. First, it is baked in the Amp Pro oven on a rotisserie that burns off dirt, oil, sludge, paint, and more. Next, the block was placed (while bolted to the same rotisserie) into the second Amp Pro machine. While rotating inside this machine, stainless wire media is blasted inside and out to fully clean the block. For the third step, the block is rotated and shaken side to side to shake out any rust particles or stainless media.

At IDM, each cylinder received a .025-inch over-bore on a Rottler boring machine. This machine self-centers each cylinder before cutting for a rough bore that is perfectly round and straight.

After boring, the cylinder wall thickness was sonic checked on the major and minor side and throughout each cylinder. The Chrysler LA motor is a thin-wall casting that must be checked before any type of performance buildup. Be sure there is at least .175-inch thickness between the bore and water jacket. Fortunately, our '72-casting 340 showed over .200 inch, and as much as .250 inch, in all of its cylinders, giving us the green light to move on.

The Scat rotating assembly features Icon forged aluminum flat-top pistons (PN KB744+.070, for a 4.070-inch bore) with full floating pins and spiral locks. The deep valve reliefs will provide plenty of piston-to-valve clearance for the .600-inch-plus lift COMP Xtreme Energy solid street roller cam we'll be using. These pistons are rated to provide 11.2:1 compression with a 68cc combustion chamber, and 10.8:1 compression with a 70cc chamber. They are lighter and stronger than stock, which will help the engine rev quickly.

Another essential part of the rotating assembly is Scat's forged 4340 I-beam connecting rods (PN 2-ICR6123-2124). These heavy-duty rods include rugged ARP bolts, plus they are designed to provide sufficient rod-to-block stroker clearance. They're made to handle up to 800 hp.

These high-quality components are also included and finish off the Scat rotating assembly: Total Seal file-fit rings (PN ST4070-5), Clevite rod bearings (PN MS-540H), and Clevite main bearings (PN CB-481HN).

Each main journal cap was cut precisely to be perfectly flat on a Sunnen cap-grinder machine. Most production caps will show to be on a 1- to 5-degree tilt. When a main cap has a slight tilt, there will not be even clearance across the bearing or an even torque load at the fastener.

In this first installment, we'll feature the important details of cleaning, precision machine work, prep, and re-cleaning that is of the utmost importance before assembly of a short-block. Also of importance for a long-lasting engine is the choice of strong, durable, quality components for the rotating/reciprocating assembly, valvetrain, and oiling system. For the high-quality engine parts we needed for this type of engine build, we put in a call to Scat, COMP Cams, and Milodon. Follow along and see the precision blueprinting machine work our friends at IDM Speed and Machine helped us put into this stroker small-block.

What To Get! Description: PN: Cost: Scat 340/416 rotating assembly 1-48013BI $1,842.97 COMP Cams Xtreme solid-roller cam kit CL20-740-9 $719.97 COMP Cams Hi-Tech timing set 3103 $64.97 Milodon main studs 81186 $96.97 Milodon head studs 80236 $129.97 Cometic MLS head gaskets (4.125-inch bore) C5457-040 $103.17 Eastwood Ceramic Engine Paint, 1 quart 51619ZP $34.99 Eastwood Urethane Activator 21854Z $14.99 Clean block (Amp Pro three-step) n/a $80.00 magnaflux block n/a $55.00 Sonic test block n/a $80.00 Cylinder boring & honing (torque plate) n/a $240.00 Align honing mains n/a $150.00 Square deck block n/a $120.00 Install cam bearings n/a $30.00 Install freeze and galley plugs n/a $20.00 Assemble short-block n/a $250.00 Degree camshaft n/a $60.00The stroked 340 small-block that's the subject of this story will be implanted into the Slick Challenger you've been following…

Each perfectly flat main cap is torqued to spec, then measured. Each cap is remeasured many times during the line honing process until each cap measures precisely the same. Notice the Milodon main studs (PN 81186). These studs will add that extra measure of strength holding the mains and crankshaft in place.

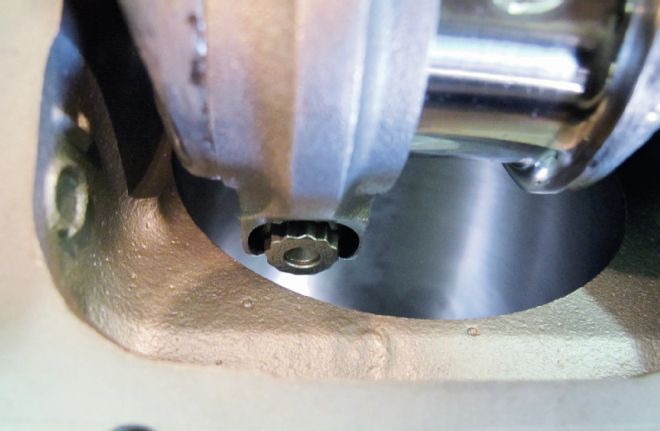

Next, we placed the Scat 4.000-inch stroke 4340 forged crank (PN 4-340-4000-6123) in the block. Connecting rod-to-block clearance was plentiful at .080 to .100 inch (.060 inch minimum). The crankshaft counterweights showed sufficient clearance at .040 to .060 inch (.040 inch minimum). Scat has strived to offer a stroker kit that will not need any clearance grinding to the block. It's still a good idea to check stroker clearance, as block castings can differ.

Next, we checked the piston-to-deck height at each corner of the block. The left deck checked in at .012 inch, front; and .015 inch, rear. The right deck was .008 inch, front; and .004 inch, rear. Most production blocks do not have square decks and will require machining to be level.

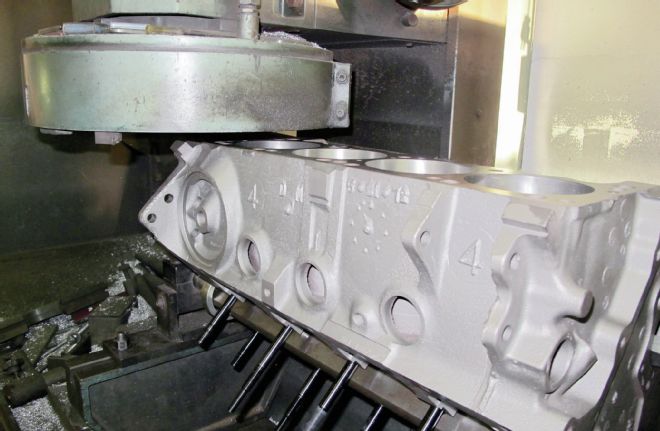

On IDM's large Kwik Way surface machine, our block was square-decked so there would be a .003-inch piston-to-deck height at each corner and across the deck. Shop owner and master machinist Ed Hickey performed this task and used CBN-type cutters for an ideal deck surface for the Cometic MLS head gaskets we'll be using.

IDM then honed the final .005 inch on a Sunnen CV-616 Cylinder King for the .030-inch overbore. Cylinder honing with deck plates simulates the head being torqued in place for perfectly round cylinder bores. Milodon studs (part No. 80236) were used to secure the torque plate and will provide the same torque load to the block and heads when the engine is assembled.

Eastwood's Ceramic Hi-Temp Engine Paint (Chrysler Blue, PN 777 51619 ZP) is said to withstand temps up to 650 degrees. It's more heat-, chemical-, and chip-resistant than any spray can engine paint. It can be brushed or sprayed on but needs to be mixed with its activator first (PN 21854Z).

We then installed new PTFE-coated cam bearings from Dura-Bond (PN PDP-16T), then the Scat crank, timing set (COMP Hi-Tech, PN 3103), and cam (a COMP Xtreme Energy solid-roller and lifter kit, 248/254 degrees duration and .616-/.622-inch lift with 1.6 rockers, PN CL20-740-9). These were final installed only after checking the rod and main clearances. The cam card specified an installed centerline of 106 degrees for 4 degrees of advance. We elected, however, to leave our cam at its dot-to-dot installed centerline of 108 degrees, for 2 degrees of advance over spec.

Here's our assembled short-block awaiting its Milodon Road Race oil pan, Edelbrock RPM aluminum heads, and RPM Air-Gap intake. These components will make a nice combination for a strong-running, pump-gas small-block. Next time we'll finish up with the long-block.