Perfect paint is an illusion. It doesn't exist—at least, not in the real world. But it's a goal we can strive for and improve our work in the process. The reality is that spraying the paint is not the most difficult or the most time-consuming part of the job. I like to say that spraying is the reward we get for doing all the hard work that goes into the prep work. Yes, you need skill to spray paint, but it's a quick study compared to bodywork, blocking, and surface refinement. The masters will tell you there's no trade out for time investment, and the more you put in, the more your paint job will give back. To think that we could stuff 30 years of experience into a magazine article that shows you everything you need to know to get perfect paint is silly, but what we can and will show you are some great techniques that will send you on your way to improving your skills. The rest is up to you.

ZedSled, our 1978 Chevrolet Camaro Z28, was always meant to look good, but has to stay on a reasonable budget. Not many people have a six-figure budget for building a car, so we set out to see if we can build the car at a fraction of that cost using salvage-yard parts, cost-effective materials from Eastwood, and old-fashioned sweat equity. The build doesn't end with the finished paintjob, and there's still a ton more work to do, but we're getting closer to meeting that goal, and we're proud of the progress so far. The message we want to share is that painting is not a talent, but rather a skill that can be learned, and preparation is king. If you invest in learning paint-and-body skills on your own, the only check you have to write is for materials and paint. There's always going to be costs involved with restoring or improving our vehicles, but these skills can actually pay you back!

1 ZedSled had been painted once over the original coat, so it wasn't too horrible stripping it to metal with soda and mechanical sanders. The process revealed a much more corroded body than we thought, but that's typical.

2 We replaced the rotten metal with the help of National Parts Depot and bathed the raw sheetmetal in Eastwood's 1:1 black epoxy primer to keep it from rusting again.

3 I prefer to do my bodywork on top of epoxy so there's maximum protection against flash-rusting. We used Eastwood fillers to fix the imperfections in the 37-year-old sheetmetal.

4 Polyester primer/surface is spray filler; it's the last stage of bodywork in most custom shops and builds like crazy. Spray three coats of poly and you've got more than enough material to straighten out your panels with a long board.

5 The firewall was smoothed and plated where the ugly wrinkle typically sits above the trans tunnel. After fillers, poly surfacer will help clean up the firewall and smooth the OE warts.

6 The first round of poly is three coats thick, approximately 12 mils of primer (most will end up in powder on the floor).

7 A guidecoat helps "read" the surface while blocking and is a necessity for flat bodywork. It's a visual aid and lets you know when you've leveled the surface from the top down. Eastwood's spray guidecoat is not paint and won't gum up your paper.

8 The first round of blocking was with 120-grit, which is very aggressive and levels the primer fast.

9 Sanding blocks are a must, as are soft sanders that are designed to fit the shapes of your body contours and help refine the surface of your panels.

10 Between sessions of blocking and priming, the surface must be perfectly clean. Eastwoods Pre Painting Prep is used to wipe the panels before additional coats of primer.

11 A huge 2.0 fluid tip in the Concours Pro gun is used to spray the poly surfacer. Remember, this is spray filler—it's thick and doesn't flow quickly. It needs to be sprayed through a huge orifice.

12 After a guidecoat, round two of blocking (this time with 180-grit) will further refine the shape and straighten the panels.

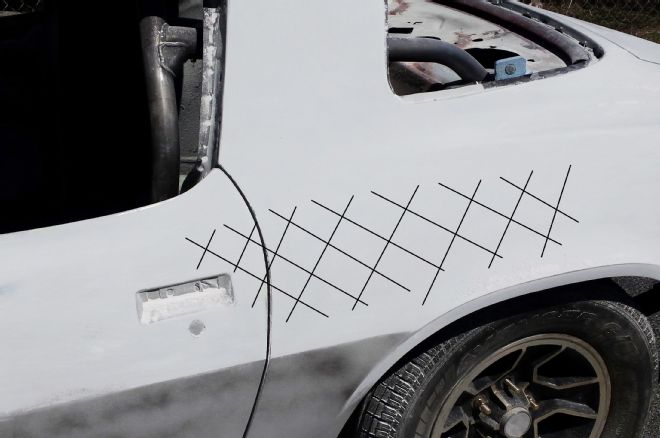

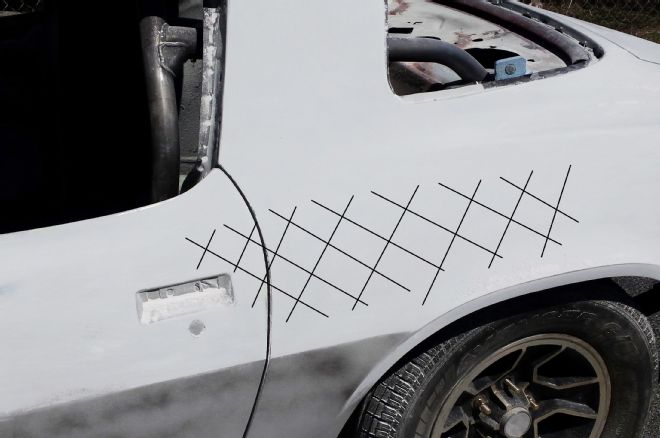

13 When you're blocking, think about chopping wood, using a cross-hatch pattern to remove more primer faster. A cross pattern also keeps your surface level.

14 After blowing off the blocking dust, the Sled gets wiped down once more to prep for the next round of primer.

15 Eastwood's 2K Urethane primer comes in white, tan, and black—black being the perfect color for ZedSled since it's getting a black topcoat.

16 Our Concours Pro 2 gun comes with a 1.3, 1.7, and 2.0 fluid tip, which makes it a versatile gun that's ready for all the coatings we need to spray.

17 3M's PPS cup-liner system saves time, money, and paint thinner, making it an environmentally friendly and cost-effective addition to our paint shop.

18 These 3/8-inch ID air-hose fittings are a necessity in any paint shop. High-volume, low-pressure (HVLP) guns depend on air volume (cfm), not pressure, and 3/8 fittings are mandatory for optimal air volume and proper atomization of any high solids product.

19 All the panels get three flatcoats of Eastwood 2K urethane primer.

20 After it's dry, the satin look of the panels makes us want to do a tough-looking, rat-rod second-gen. Note the stock extractors mounted from the inside of the fender.

21 The firewall is very visible and gets the same treatment as the exterior panels on this build. At this stage, it's not much more work to commit to smoothing a few more panels, and it will pay off big time when the car is done.

22 F-body guys know the struggles of the flimsy bumper covers on the 1978–1981 Camaros, and a flex agent helps keep the high-build primer from cracking and flaking under blocking and shaping. It gets mixed 10 percent by volume.

23 The front and rear fascia get three coats of the 2K primer (with flex) and are blocked with 180-, 220-, and final sanded with 320-grit—just like the steel panels—and reprimed, if necessary.

24 A dual-action sander is a great tool when used correctly, and when you sand only the flat panels, you can be very efficient in prepping the surfaces for paint. We're using 320-grit for final sanding.

25 Using 320-grit on a soft sander helps properly block the curved areas. Fingers cause ripples that can show through the paint; sanders and blocks are flatter than our fingers.

26 With the panels mounted on stands, they can be thoroughly washed, minimizing the dust that can be blown back into the paint in the booth. Clean panels are absolutely necessary, and dishwashing soap is the best thing to use because of its high PH value.

27 Cleaning the parts is done in several stages, starting with an alcohol wipe, which acts as an anti-static and keeps parts cleaner in the paint booth.

28 An aerosol glass cleaner offers another layer of clean, taking care of organic contamination.

29 If you don't have a paint shaker, get your jobber to shake the paint for you or spend lots of time stirring. Paint separates in the can and needs to be agitated. We're using Eastwood's Boulevard Black as the topcoat color for ZedSled.

30 The last step before spraying paint is a wipe-down with a tack rag. This picks up any airborne dust that may have fallen onto the panels.

31 The base color gets a minimum of two coats, though you typically need more with lighter colors. Dark colors like black have strong pigments and covers faster.

32 After 30 minutes waiting after the last coat, the panels get another tack-rag session before clear.

33 Eastwood's Premium Show Clear is a 4:1 mix, with the option of additional reducer for better flow.

34 Using the same Concours Pro gun with the same 1.3 fluid tip as used to spray the base color, every panel gets three full wet coats of clear.

35 The gloss is brilliant, and we're feeling euphoric to finally see new color on these old panels!

36 Masking any car is easier with no doors, windows, or trim, but the best benefit is that doing so eliminates tape lines at panel breaks.

37 After the clear has dried, you can finally see how the hours of bodywork and gallons of primer have paid off.

38 Here's an example of why to spray a car "exploded" (disassembled). The jambs, which are usually an afterthought, get the same slick finish as the rest of the body. These details will make you proud.

39 It took about five hours to spray the car from start to finish, and there are small particles that have fallen into the paint between coats and while spraying. Surface correction is the next step in the job and starts with 1,000-grit on a sander, working only the flat panels with the machine and using a very light touch, stopping after the surface is broken and dull.

40 Wiping down the panels between sanding sessions lets you check your progress. We're using a spray glass cleaner to lift the dust off the panel.

41 The next session is 1,500-grit, which further refines the surface and helps remove texture from the clear, after the 1,000 has removed the surface dust.

42 Eastwood has an alternative to machine-sanding with small multi-packs of ultrafine paper, including TRIZACT 3,000 grit for the final stage, which makes buffing much easier.

43 Using slightly soapy water with the 3,000-grit TRIZACT, everything gets sanded one last time, making four passes over every sanded panel.

44 The Norton Liquid Ice system uses three pads and one single compound that breaks down with use. It works beautifully to bring the sanded panels back to full gloss.

45 The first step is a to use a wool pad at 1,200 rpm. This is quite coarse, but it removes the sanding scratches and preps for the next refinement stage.

46 Glass cleaner is used to remove haze and dust, and we used it to check the surface to see if we're ready for the next pad and also to remove contamination before buffing again. We do this between every pad change.

47 The blue pad is foam and finer than the wool, but still aggressive. This stage cleans the "haze" off the surface and further refines the gloss and distinctness of image reflection (DOI).

48 After cleaning again, the last buffing step is the white foam pad, which has a velvety feel. The same compound is used for each step, using chemistry to enhance and build off each previous step.

49 A clean microfiber cloth gets any residue off the panels and lets you do a final check at the same time.

Here's the time breakdown for our labor on this job so far.

Rust repair: 35 hours

Body/Filler work: 250 hours

Priming and blocking (two polyester sessions, two urethane sessions): 80 hours

Masking and paint: 22 hours

Sanding and buffing: 18 hours

Add those up and we've got just above 400 labor hours. So here's the question: Do you write the check for roughly $20,000 (400 hours multiplied by $50)? Or do you invest in your own skillset and do it yourself? Trust us when we say it's worth it to invest in yourself—you'll thank us later.