Spray-on rubberized coatings are a popular alternative to paint, and it's no surprise why—they're versatile, easy-to-use, and are easy to remove (relative to paint). Several companies make similar coatings: Performix Brand Adhesives makes Plasti Dip, the brand most often associated with this type of coating, and others are available from Rust-Oleum and Duplicolor. This month, we tried ElastiWrap, one of the newest peel-off coatings on the market, and we're happy with the results so far.

What Is It?

ElastiWrap is formulated and sold by The Eastwood Company; product manager John Robinson describes it as a "high-tech coating made from rubber, flexible agents, and VOC-compliant carrier solvents." That last bit about being VOC-compliant is key. Because it conforms to current pollution standards, Eastwood can ship gallon-sized containers of ElastiWrap to all 50 states. Non-VOV-compliant products are only available in smaller aerosol cans in regions with tight pollution controls. Being able to buy a large quantity is advantageous when coating something big like a car—a couple gallon cans will do the job, whereas you may need a couple dozen aerosol cans of a non-VOC-compliant product.

We also spoke with regular CC contributor and autobody specialist Kevin Tetz about rubberized coatings in general, and he told us these products evolved from coatings used to make non-slip, cushioned tool handle grips (like on the side cutters in the accompanying photo). The tool handle was literally dipped into (or sprayed with) the coating. Repeated applications cause the coating to build a thick film, similar to how wax candles are made. "Somewhere, someone must have thought, ‘If it works for my tool handle, maybe it will work on my car,'" Tetz posited. He's a fan of the coatings, saying, "They are less expensive than paint, and they are extremely versatile. They have the appearance and aesthetic of paint, and they can act as protective coatings like a chip and rock guard on rocker panels and around wheel openings." He cautioned that they're not a replacement for paint. "You can't buff it. If the coating is damaged, it will need to be removed and reapplied. Think of it as a temporary coating." From that perspective, peel-off coatings are well suited for race cars that may see color or graphics changes from season-to-season. It's a lot less expensive than repainting the car too. "Different colors are available, as well as metal flake and clear coatings," Tetz added. "You can mix the colors, too, and create a custom color. That gives the owner lots of room for creativity." As this is written, Tetz is working on coating an entire car with custom-mixed ElastiWrap. We will cover that "paint job" in an upcoming issue.

Parts List DescriptionPNSourceCost Turbine Paint Gun System14878Eastwood57.99 Burn Out Black (gallon)55615049ZPEastwood99.99

We were jazzed to get started using this stuff, so Eastwood sent a gallon of its Burn Out Black, which dries to a semi-gloss finish. After stirring, ElastiWrap is ready to spray straight from the can—no reducing is needed.

ElastiWrap works best when sprayed from a gun set up with a 1.6- or 1.8-fluid tip. You can use your primer gun or try Eastwood's Turbine Paint gun system (shown here). At about $60, it's very economical. It puts out a lot of air, but it's quiet. Unlike airless sprayers, which sound like tattoo needles on steroids, this thing is quieter than a vacuum cleaner. Plus, there's no air compressor cycling on and off.

The Turbine paint gun comes with a 1.8-fluid tip. The fluid tip and air cap are not precise enough for spraying an automotive base- or clearcoat, though the gun is affordable and convenient enough that you may be tempted to do so. Designed to spray thick coatings like high-build primer or ElastiWrap, the Turbine did its job perfectly.

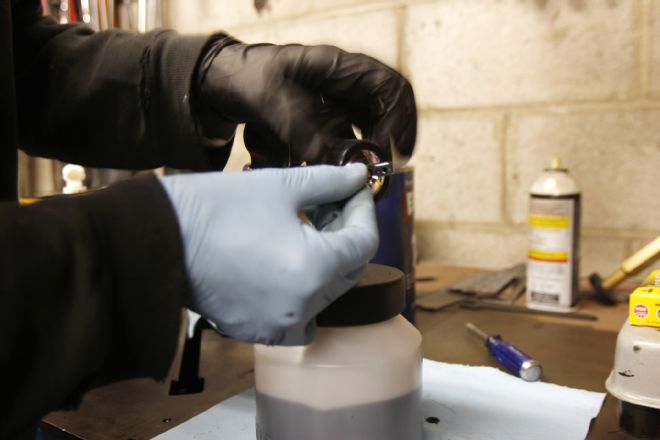

Gun set-up was simple: pour the coating in the reservoir and you're ready to spray. Even with a full reservoir, the Turbine gun is light and maneuverable. Author's note: Time for new gloves! We only had one of each color left.

We decided to try the Burn Out Black on our Project Cutlass drag car's quarter-panel, a spot where real tire rubber would accumulate. Ideally, we would use clear ElastiWrap here and just peel off the layer after a weekend of racing, if we were so inclined. Eastwood's directions recommend applying ElastiWrap to a clean, smooth surface with a light coating of wax on it. This makes it easier to peel off the coating later. We fogged the area with some spray wax and wiped it clean with a terry-cloth towel.

Next, we masked the upper half of the quarter-panel, leaving a hard tape line. The hard edge will also make the product easier to peel off than if we had let the coating fade into the upper half of the panel.

ElastiWap is easy to spray. Though it looks thick and textured just out of the gun, the material flows out to a smooth surface as it dries. The instructions specifically recommend two medium coats, with 15 to 20 minutes of drying time each, as the ideal foundation. After that, spray at least four to six more coats. This gives you enough buildup of the material to make it easier to remove later.

Dry times between coats are longer than we are used to with paint, but ElastiWrap is definitely easier and more forgiving to spray. A simple charcoal respirator is recommended, but the chemical smell is far less than with traditional paints and primers.

If you did any masking, Eastwood recommends removing the tape as the last coat is still drying because the tape will be easier to pull with less risk of taking chunks of the coating with it.

So here's our Burn Out Black tire-rubber barrier. As mentioned before, this was an experiment. If we really wanted a chip and rubber guard, we'd use clear ElastiWrap instead. Either way, we were pleased with the coating's appearance once it dried. It's worth noting that we had trouble getting our cheap, old roll of masking tape to stick to the quarter-panel, and that's why the tape line is not straight. In the future, we would prep the panel with a wax and grease remover, apply the tape and masking material, then spray the surface to be coated with wax. Doing so would ensure the masking tape stays were we want it to.

We were curious about how ElastiWrap would cover an unprepped surface, so we also sprayed a swath across a replacement tailgate for our C10. We were surprised to find ElastiWrap covers and hides more flaws than we imagined—more than some filler-primers we've used in the past, so the surface doesn't need to be prepped as if for paint prior to spraying ElastiWrap. You could probably get away with a final prep with 400-grit sandpaper and still get good coverage. It will, however, be more difficult to peel off the coating with so many dips and valleys in the panel, so be aware that better prep from the outset will save you work later.

ElastiWrap can be cleaned with mineral spirits if you happen to spill any or get some where you don't want it. We've also read users online recommending Glue-Gone or similar cleaners.