Why is this man smiling? If the lead photo looks familiar, that's because a similar version has appeared within the pages of R&C before. That was back in April 2012 as part of a family style tech article where Smilin' Sam Strube's own mom recreated her woodgraining on the dash rail and garnish moldings of the newly reacquired 1930 A coupe that she and Strube's dad restored together back in the 1970s.

The Strubes are a tight gearhead group. Strube and his brothers, John and Matt, have known the old coupe for the better parts of their lives, so when it surfaced on an Interweb auction site, Strube brought it back home where it belongs—where upgrades immediately got underway.

Sometimes, however, life's little speed bumps can stall our hot rod projects. But there still exists an age-old remedy for such situations. Back in the day, before we had professional rod shops to turn to for tasks outside of our personal skillsets, hot rods were commonly built at home. The second-generation rodders amongst us have likely observed collaborations where ringers with varied specialties were brought into the residential garages of our fathers and their friends. Although we don't read much about it, this type of reciprocating camaraderie is still alive and well—where friends don't leave friends stuck on a hot rod hump.

Since its restoration in the 1970s, the Strube family coupe had fiberglass parts, which Strube did not care for. A swap meet rendered fenders. They were real steel, but in serious need of attention, and although Strube is a multi-talented builder, he does not claim to be a body guy. It was Don Dillard of Highway 99 Hot Rods in Tulare, California, who hatched the plan to help our friend over his personal hot rod hump. Dillard picked the players and recruited the talents of body guys like Richard Wright of Fallon, Nevada, and even yours truly, to assist with necessary fender-mending, as he, Strube, Tim Sage, and Simeon Kennedy (from the local-to-Livermore area) tended to the stalled project's mechanical needs. Yep, a good old-fashioned hot rod work party was on!

1. What comes next won’t be pretty, but it will be productive and at the very least, fun. Y’all may now prepare to witness flying sparks, flashing arcs, and various airborne impurities in flight. But first let it be said that the tag team tech to follow is not just another how-to. Consider this a why-to.

1. What comes next won’t be pretty, but it will be productive and at the very least, fun. Y’all may now prepare to witness flying sparks, flashing arcs, and various airborne impurities in flight. But first let it be said that the tag team tech to follow is not just another how-to. Consider this a why-to.

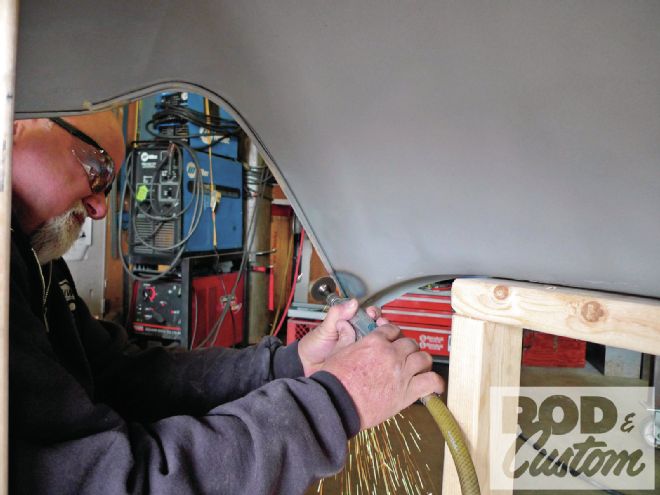

2. Backed by his totem pole of welding equipment, Strube begins to repair the first of several fender fractures.

2. Backed by his totem pole of welding equipment, Strube begins to repair the first of several fender fractures.

3. Out in the driveway where the entire neighborhood can enjoy the soothing sounds of hammering, and the screaming of unregulated air tools, Dillard begins by cleaning out low spots in need of repair. A Harbor Freight Central Pneumatic die grinder, properly outfitted with a 3M Clean & Strip Disc, is the hot tip for this step.

3. Out in the driveway where the entire neighborhood can enjoy the soothing sounds of hammering, and the screaming of unregulated air tools, Dillard begins by cleaning out low spots in need of repair. A Harbor Freight Central Pneumatic die grinder, properly outfitted with a 3M Clean & Strip Disc, is the hot tip for this step.

4. The fenders had been media blasted just prior to our arrival, which enabled us all to make the best possible use of our time. Here Rich begins with a 9-inch body disc to remove some very old Black Magic–brand body filler.

4. The fenders had been media blasted just prior to our arrival, which enabled us all to make the best possible use of our time. Here Rich begins with a 9-inch body disc to remove some very old Black Magic–brand body filler.

5. Surprisingly, all four fender beads were unbroken. Perhaps the farm-style reinforcements helped them survive. They’re mighty strong, but mighty ugly, so Strube fires up the old Bernzomatic and begins heating the brass.

5. Surprisingly, all four fender beads were unbroken. Perhaps the farm-style reinforcements helped them survive. They’re mighty strong, but mighty ugly, so Strube fires up the old Bernzomatic and begins heating the brass.

6. But that didn’t work, so Dillard whittles the brass down with another die grinder—this time with a thin cutoff disc attached.

6. But that didn’t work, so Dillard whittles the brass down with another die grinder—this time with a thin cutoff disc attached.

7. Here Dillard has taken a tip from Rich Wright. As 9-inch body discs go, 50-grit is considered quite fine. A worn disc of this type will still work well as a highlighter, but also as a shrinking tool for the larger expanses, as it generates heat without removing too much precious metal.

7. Here Dillard has taken a tip from Rich Wright. As 9-inch body discs go, 50-grit is considered quite fine. A worn disc of this type will still work well as a highlighter, but also as a shrinking tool for the larger expanses, as it generates heat without removing too much precious metal.

8. By the second day, our metal-working chores were close to done. Here, before filler work begins, Wright makes a quick pass around the fender beads with a Harbor Freight Central Pneumatic angle die grinder. With a 3-inch, 3M Roloc disc attached, the crevice is cleaned quickly.

8. By the second day, our metal-working chores were close to done. Here, before filler work begins, Wright makes a quick pass around the fender beads with a Harbor Freight Central Pneumatic angle die grinder. With a 3-inch, 3M Roloc disc attached, the crevice is cleaned quickly.

9. With all the thumping and bumping going on, a fender-to-brace reinforcement—actually two fender-to-brace reinforcements—has broken loose and will need to be welded back in place.

9. With all the thumping and bumping going on, a fender-to-brace reinforcement—actually two fender-to-brace reinforcements—has broken loose and will need to be welded back in place.

10. First things first: We’ll need to clean things up a bit. Obviously, there’s no lack of trust between these two teammates.

10. First things first: We’ll need to clean things up a bit. Obviously, there’s no lack of trust between these two teammates.

11. As Wright performs a quick preparatory grind, Strube is already poised in position and ready to proceed with the next step.

11. As Wright performs a quick preparatory grind, Strube is already poised in position and ready to proceed with the next step.

12. With the necessary preparations made, Strube gets to welding once again and the previously dislodged reinforcement becomes one with the fender once more.

12. With the necessary preparations made, Strube gets to welding once again and the previously dislodged reinforcement becomes one with the fender once more.

13. Wait a minute. What just happened here? That doesn’t look like a taillamp-mounting hole, now does it?

13. Wait a minute. What just happened here? That doesn’t look like a taillamp-mounting hole, now does it?

14. After grinding, a small chunk of brass is firmly secured behind the accidental hole, and the problem is quickly remedied as Strube demonstrates a little maneuver that shops call “the OSHA squint”.

14. After grinding, a small chunk of brass is firmly secured behind the accidental hole, and the problem is quickly remedied as Strube demonstrates a little maneuver that shops call “the OSHA squint”.

15. Around about this time, the geezerly amongst us are getting pretty tired and sore, but it could be worse. Strube’s wooden fender jigs are lifesavers. So far, they’ve held the fenders tight, at just the right height.

15. Around about this time, the geezerly amongst us are getting pretty tired and sore, but it could be worse. Strube’s wooden fender jigs are lifesavers. So far, they’ve held the fenders tight, at just the right height.

16. As we work our way toward filler time, Dillard gives the bare steel a good going over with 3M Gold 80-grit on a 6-inch DA (dual-action) sander.

16. As we work our way toward filler time, Dillard gives the bare steel a good going over with 3M Gold 80-grit on a 6-inch DA (dual-action) sander.

17. Y’all may now behold the greatest innovation to come to the autobody trade since Black Magic brand body filler! Just in from the lab, Big Broham magnetic body filler is here!

17. Y’all may now behold the greatest innovation to come to the autobody trade since Black Magic brand body filler! Just in from the lab, Big Broham magnetic body filler is here!

18. Unfortunately, the trial-size container of Big Broham would not be enough. So, for the job at hand we’ve opted to substitute Evercoat’s Rage Gold.

18. Unfortunately, the trial-size container of Big Broham would not be enough. So, for the job at hand we’ve opted to substitute Evercoat’s Rage Gold.

19. It’s always fun to work with new and different people, and that’s how we learn new tricks. Well, here’s an old trick. Wright has just hipped us to “stink block!” It’s just an old chunk of pumice, which quickly conforms to the curvatures of these types of fenders—like a form-fitting fairing board.

19. It’s always fun to work with new and different people, and that’s how we learn new tricks. Well, here’s an old trick. Wright has just hipped us to “stink block!” It’s just an old chunk of pumice, which quickly conforms to the curvatures of these types of fenders—like a form-fitting fairing board.

20. At this stage, the old body guys are tired, sore, and down to the short strokes on our filler work.

20. At this stage, the old body guys are tired, sore, and down to the short strokes on our filler work.

21. But the mechanics and fabricators on this crew have been real busy too.

21. But the mechanics and fabricators on this crew have been real busy too.

22. This has been a truly noisy weekend, yet the neighbors don’t complain. Truth be told, it’s a hot rod neighborhood. Here Strube’s hot-rodding neighbor, Simeon Kennedy joins in to throw some sparks.

22. This has been a truly noisy weekend, yet the neighbors don’t complain. Truth be told, it’s a hot rod neighborhood. Here Strube’s hot-rodding neighbor, Simeon Kennedy joins in to throw some sparks.

23. Meanwhile, outside in Strube’s other driveway, plumbing was completed, fluids were added, and someone even volunteered to run for High-Test. Just a few glubs later, the fresh engine was lit—and sounding pretty playful too!

23. Meanwhile, outside in Strube’s other driveway, plumbing was completed, fluids were added, and someone even volunteered to run for High-Test. Just a few glubs later, the fresh engine was lit—and sounding pretty playful too!

24. Using an infrared thermometer, Strube is checking each exhaust tube for even temperature, which helps to confirm proper spark, as well as valve and carburetor adjustments. A few short instants later he was giving E-ticket rides—barking brand-new 700-16 Coker/Firestones and having a ball ripping up and down the street.

24. Using an infrared thermometer, Strube is checking each exhaust tube for even temperature, which helps to confirm proper spark, as well as valve and carburetor adjustments. A few short instants later he was giving E-ticket rides—barking brand-new 700-16 Coker/Firestones and having a ball ripping up and down the street.

25. Sam Strube’s much better half, Katie, got the first ride. Next up was their youngest son, Cal. And so it went, and went, and went—’til the sun went down that night.

25. Sam Strube’s much better half, Katie, got the first ride. Next up was their youngest son, Cal. And so it went, and went, and went—’til the sun went down that night.

26. We now have a set of real steel fenders ready for prime time. And now that the Strube family ’30 A coupe has accumulated its first few break-in miles around the neighborhood, our work here is finished.

26. We now have a set of real steel fenders ready for prime time. And now that the Strube family ’30 A coupe has accumulated its first few break-in miles around the neighborhood, our work here is finished.

27. At the end of this good old fashioned hot rod work party, well-hosted friends return to their own garages with temporarily enlarged bellies (good cooking at Casa de Strube), and a gooey, squishy feeling of satisfaction. Soon in another town, in another garage, we’ll do it again. Are you or a friend stalled at the foot of a hot rod hump? If so, try this at home.

27. At the end of this good old fashioned hot rod work party, well-hosted friends return to their own garages with temporarily enlarged bellies (good cooking at Casa de Strube), and a gooey, squishy feeling of satisfaction. Soon in another town, in another garage, we’ll do it again. Are you or a friend stalled at the foot of a hot rod hump? If so, try this at home.