Sometimes tech articles are where we find ’em. In this particular instance Mrs. Rotten and I just happened to be in the right place at the right time while visiting friends, Richard and Trish Wright, at their home/shop in Fallon, Nevada. “Hey Rich, what are you workin’ on there? Wait, that’s cool! Let me grab my new digital Brownie!”

Sure, I guess you had to be there, but Rich was just about to hammer a peak into a brand-new Vintique hot rod–style Deuce grille shell. His approach was very clever as I’m sure you’ll agree. But before we proceed with the technical portion of this tale, let’s back up a bit or two. In order to fully appreciate George Canavan’s ’31 Model A coupe project-in-progress, we must reflect back to its beginnings.

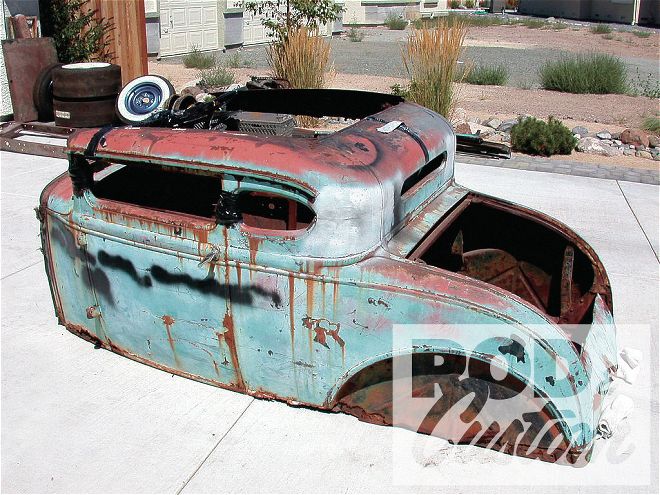

Any attempt to describe the starting point condition of the coupe project’s body would fall short, as “beyond rough” doesn’t scratch the rusty surface. This job would require some serious wand waving. The 8-inch-plus chop was crude, and off by inches according to Canavan. But fortunately the body’s previous owner had not discarded the pieces that came out of the pillars, which made unchopping a possibility. For that task Canavan called upon Aaron Valencia of Lancaster, California. With the botched chop now corrected, the remainder of the transformation is taking place in Rich Wright’s well-equipped garage.

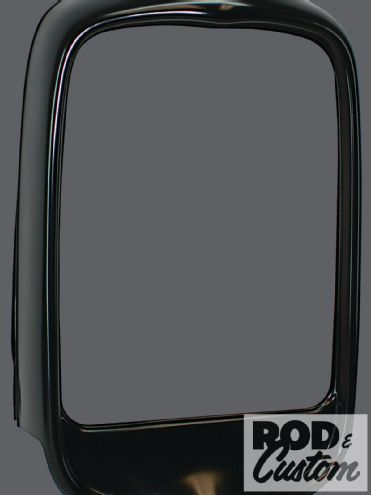

[1] From Sacramento Vintage Ford, a Vintique hot rod–style Deuce grille shell will assume its position of prominence. These are void-of-holes ’n’ hiccups. Still, the clean slate of a shell was missing something. The practice of peaking is nothing new. It’s been done for years, with lead, and later on, plastic filler, but Rich has a better idea.

[2] While we’re not quite sure whether to call this a buck, a dolly, or a fixture, it is the hot tip. Rich has made and used similar tools for peaking other types of shells in the past. This one was made by George, but under Rich’s watchful eye. A mockup version was first fashioned from cardboard, then this one from 16-gauge and 1-inch square tubing.

[3] Once satisfied with the precision fit of the buck, dolly, uh fixture thing, the shell must be lined up in position as it will be on the car so that a centerline can be established. Here in Rich’s garage, 1/4-inch masking tape is a staple, and it works well for stretching out a straight guideline.

[4] A little later on there will be welding at each end of the buck, dolly, or, let’s just refer to it as “the tool” from here on, shall we? For those who’ve noticed that Rich wields a Sharpie like a sword, there is a reason for that. In addition to being a prolific builder of hot rods, he’s also Fallon, NV’s premier pinstriper.

[5] Only a few short minutes later, the new shell is facedown, back on the bench where Vintique’s factory black has been removed from the inside where necessary. Now following the dull Sharpie guideline, the peaking tool can be carefully located just prior to welding.

[6] Next, Rich throws the switch as an experienced Miller MIG is fired up and the peaking tool gets tack-welded into place. The tack-weld attachment points are only at the extreme ends of the peaking tool where hammering need not take place.

[7] With tack welding done, the shell and peaking tool are temporarily one. The 1-inch square tubing portion of the tool can now be secured into the jaws of the vise.

[8] This arrangement just happened to hold the soon-to-be-hammered-upon shell at a comfortable working height. Still, an extra pair of hands would be nice.

[9] The timing couldn’t have been better as the car’s owner, Canavan, stopped by to assist by applying downward pressure as Rich hammer-forms the shell’s new peak.

[10] With a DA (dual-action) sander locked into spin cycle, Rich is now dressing down the worked area. This quickly chases away the slight hammer marks.

[11] After grinding the tack welds to release the peaking tool, the shell is once again fit to the car, and the newly formed peak looks right at home already.

[12] Once primed, prepped, painted, polished, and pinstriped, the all-steel, peaked shell comes as a subtle surprise. But then, this nearly finished coupe is chock-full of subtle surprises.