When Air Ride Technologies came on the scene in 1996, the company's founder, Bret Voelkel, was known for his killer homebuilt Pro Street Mustang, but not many expected he and his newly created firm would go on to revolutionize the aftermarket suspension scene, but that's what happened.

A talented designer/fabricator, an astute businessman, and rumor has it a pretty good guitar player, Bret has never stopped moving his organization forward, which is why the company is now called RideTech and includes a broad array of suspension products, TigerCage rollbars, and now a new line of shocks and coilovers. As the team at RideTech describes them, shock absorbers are the brains of the suspension system and nothing influences ride and handling more.

Contemporary shocks can be divided into two categories, twintube and monotube:

Twintube

As the name implies twintube shocks have two cylinders, one inside another. The inner cylinder, called the pressure tube by some manufacturers, is where the piston and shaft move up and down. The outer cylinder, called the reserve tube, serves as a reservoir for the hydraulic fluid. These shocks normally contain nitrogen gas, either in a bag or mixed with the hydraulic oil, to keep the fluid from foaming.

Twintube shocks are used in many OEM applications, they are less expensive to produce than the monotube shocks and often have soft valving, which can adversely affect handling.

Monotube

Again the name describes the design. Monotube shocks have a single cylinder, however, it is divided into two sections—one that contains oil, the other gas. In the fluid chamber, motion of the chassis is transmitted via a rod that moves a piston through the oil. Below the oil is a floating and seal piston with gas on the other side. With aggressive movements of the rod piston in the fluid chamber the floating piston is pushed further into the gas section, which increases damping force.

Monotube shocks are favored for performance applications because the larger piston provides a more efficient oil flow path, which leads to cooler operating temps and more consistent performance in extreme environments.

RideTech's shocks are the monotube type and come in two basic configurations, the smooth body shocks are 1½ inches in diameter and are for standalone use. They come in a host of lengths and mounting styles are available to suit virtually any application.

The Q Series smooth body shocks come in two styles:

RQ (Non-adjustable)

The simplest version of the monotube. There are no external adjustments as all the valving calibration is done at the factory according to the vehicle and driving style of its intended use. For confident handling and stability, and for those who want to install a shock and forget it, these are a great choice.

HQ (Single Adjustable)

These shocks have a single adjustment to change the rebound (extension) properties. Adjusting the rebound setting allows the ride quality to be fine-tuned and dial in more performance-oriented handling characteristics.

Coilovers and More

For standalone, coilover, and ShockWave applications, RideTech offers their 2-inch diameter, threaded body Monotube shock. Like the smooth-body Q-series, these shocks come in RQ non-adjustable and HQ single-adjustable versions.

In addition, threaded-body shocks come in the following styles:

TQ (Triple adjustable)

These shocks have a single rebound adjustment and a dual-stage (high-speed and low-speed) compression adjustment. It uses a remote reservoir that is connected with a 30-inch braided line for easy installation in a variety of applications. The high-speed adjustment allows tuning for impact harshness…potholes, speed bumps and other harsh road irregularities that might induce a high-speed movement of the piston rod. The low-speed adjustment allows tuning of ride quality, as well as the general cornering characteristics of typical road course and racetrack use.

Select Series

These sophisticated electronically controlled shocks offer a cruise mode for a soft, compliant ride and a sport mode more for more aggressive driving and performance all at the touch of a button.

The Seat-O-Meter

There are a number of sophisticated methods to evaluate shock absorbers, but far and away the best tool is in the seat or your pants. When your butt is planted in the driver seat you'll know in short order if they're right for the way you drive. The proper shock absorbers can turn a rough riding truck into one that is smooth and comfortable cruiser; there are shocks that can help your truck carve corners on the street or track, then there are those that can do it all with the turn of a knob or the push of a button. Whatever your needs, RideTech has a shock to do the job, we're sure the seat of your pants will agree.

1. After years of research and development Bret Voelkel collaborated with Fox and came up with a shock absorber worthy of the RideTech name. This example is a smooth-body, non-adjustable RQ series.

1. After years of research and development Bret Voelkel collaborated with Fox and came up with a shock absorber worthy of the RideTech name. This example is a smooth-body, non-adjustable RQ series.

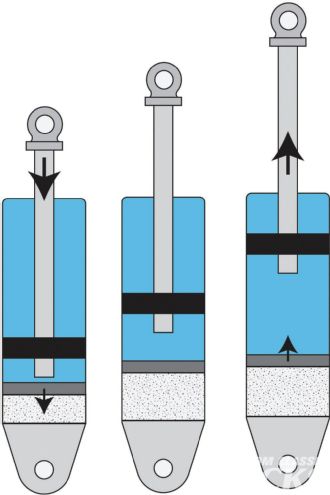

2. RideTech shocks are the monotube style. The upper piston operates in an oil-filled chamber, below it is a floating piston and seal over a nitrogen-filled chamber.

2. RideTech shocks are the monotube style. The upper piston operates in an oil-filled chamber, below it is a floating piston and seal over a nitrogen-filled chamber.

3. One of the many advantages of a monotube shock is the larger piston (left) when compared to the twintube style. The bigger piston provides superior fluid control and lower operating temperatures.

3. One of the many advantages of a monotube shock is the larger piston (left) when compared to the twintube style. The bigger piston provides superior fluid control and lower operating temperatures.

4. On light movements the floating piston does not move far and gas provides a cushioning effect—on aggressive movements the floating piston is forced down further (because the oil in the upper chamber is restricted by the valving), which increases damping. In effect, monotube shocks vary the damping according to conditions.

4. On light movements the floating piston does not move far and gas provides a cushioning effect—on aggressive movements the floating piston is forced down further (because the oil in the upper chamber is restricted by the valving), which increases damping. In effect, monotube shocks vary the damping according to conditions.

5. Single-adjustable shocks have a knob that alters rebound characteristics. Double, triple, and electronically adjustable shocks are also available. Adjustments should always be made starting from the full-stiff position. Double- and triple-adjustable shocks should have the compression adjustment made followed by the rebound adjustment

5. Single-adjustable shocks have a knob that alters rebound characteristics. Double, triple, and electronically adjustable shocks are also available. Adjustments should always be made starting from the full-stiff position. Double- and triple-adjustable shocks should have the compression adjustment made followed by the rebound adjustment

6. To provide smooth movement throughout the range of travel spherical bearings are used in 2-inch body shocks. Spacers are available to accommodate ½ or 5⁄8-inch bolts.

6. To provide smooth movement throughout the range of travel spherical bearings are used in 2-inch body shocks. Spacers are available to accommodate ½ or 5⁄8-inch bolts.

7. Q-Series smooth body shocks are available in an in a range of lengths and in all the common mounting configurations. Here the application is a typical Mustang II IFS under an early Chevy pickup.

7. Q-Series smooth body shocks are available in an in a range of lengths and in all the common mounting configurations. Here the application is a typical Mustang II IFS under an early Chevy pickup.

8. In the rear, the same truck has been fitted with non-adjustable RQ series shocks. To maintain and protect the exterior of the shocks they are hard-coat anodized.

8. In the rear, the same truck has been fitted with non-adjustable RQ series shocks. To maintain and protect the exterior of the shocks they are hard-coat anodized.

Selecting Springs for Coilovers

One of the most common complaints from those with coilover-equipped tucks is poor ride quality - a problem that can almost always be traced to using the wrong springs from the application. The cure for this condition is rather obvious- choose the right springs. This trick is how to do it.

9. Thanks to the crew at RideTech the process is much easier than you might think. The first step is to weigh the truck. The goal is to establish the corner weight of the vehicle. This can be done easily with individual wheel scales (which RideTech recommends), weighing the entire vehicle then multiplying the total weight by the front end weight bias then dividing it by two, or weigh each axle individually then divide that number by two.

9. Thanks to the crew at RideTech the process is much easier than you might think. The first step is to weigh the truck. The goal is to establish the corner weight of the vehicle. This can be done easily with individual wheel scales (which RideTech recommends), weighing the entire vehicle then multiplying the total weight by the front end weight bias then dividing it by two, or weigh each axle individually then divide that number by two.

10. For independent suspension measure the distance from the centerline of the control arm pivot point to the centerline of the ball joint.

10. For independent suspension measure the distance from the centerline of the control arm pivot point to the centerline of the ball joint.

11. The next measurement is from the centerline of the control arm bushing to the point on the control arm directly under the center of the spring or the coilover assembly, then measure the angle of the centerline of the coilover from the horizontal of the control arm (or axle if calculating the rear). Armed with that information. go to the RideTech website and find the shock with dimensions suitable for your application. Then plug all the measurements into the spring calculator. You’ll be able to choose springs for a cruising/daily driving, performance driving, or racing.

11. The next measurement is from the centerline of the control arm bushing to the point on the control arm directly under the center of the spring or the coilover assembly, then measure the angle of the centerline of the coilover from the horizontal of the control arm (or axle if calculating the rear). Armed with that information. go to the RideTech website and find the shock with dimensions suitable for your application. Then plug all the measurements into the spring calculator. You’ll be able to choose springs for a cruising/daily driving, performance driving, or racing.

12. In the case of our ’64 Chevy pickup IFS, 3.6-inch stroke shocks with 8-inch, 700-pound springs were selected for daily driving; 225-pound springs were selected for the solid rear axle. All RideTech springs are made in Indiana by HyperCo, they come powdercoated and have a part number indicating the spring rate for easy identification.

12. In the case of our ’64 Chevy pickup IFS, 3.6-inch stroke shocks with 8-inch, 700-pound springs were selected for daily driving; 225-pound springs were selected for the solid rear axle. All RideTech springs are made in Indiana by HyperCo, they come powdercoated and have a part number indicating the spring rate for easy identification.