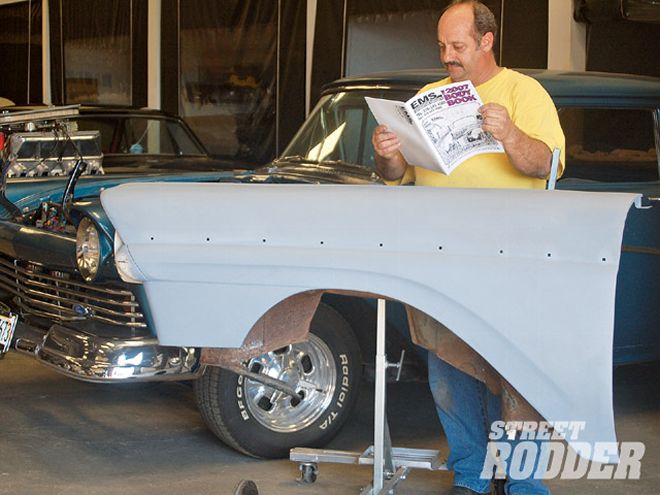

With the fender for Gary Long's '57 Ford good as new, Manny Lawrence of Manny's Repair checks out the EMS catalog.

With the fender for Gary Long's '57 Ford good as new, Manny Lawrence of Manny's Repair checks out the EMS catalog.

As street rodders continue to redefine the hobby, there are greater numbers willing to concede '49 and later rides are cool, and we couldn't agree more. After all, cars of that era make great drivers, can be built for a reasonable amount of money, and there are a surprising number around, particularly when compared to the pre-WWII vintage tin to be found.

One of the cars from the '50s gaining in popularity is the '57 Ford, but as they say, what goes around comes around. When they originally hit the showroom floors, Ford found they had a winner on their hands. By year's end the newly restyled lineup outsold Chevrolet, making Ford the number one automaker that year with over 1,600,000 vehicles produced.

But while there were lots of '57 Fords made, the ravages of time and abuse have taken their toll on many that remain. Like most cars that are five decades old (give or take a few years), rust can be an issue, but thanks to our friends at Engineering & Manufacturing Services, repairing the areas that are most commonly corroded is easier than ever. Well-known for their quality repair panels for early cars and trucks, EMS is constantly expanding their line and now offer a variety of products for '57-58 Fords, including quarter panel sections, floor pans, trunk floors, front fender caps (above the headlights), and lower fender sections. And they're adding new part numbers all the time.

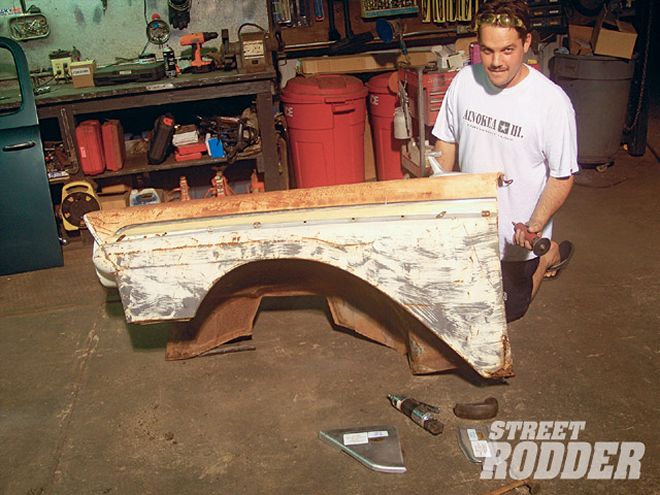

Randy Lawrence prepares to fix the rust damage typically found in the fenders of all types of cars. This example happens to be a '57 Ford, but the procedure he used is applicable to virtually any repair panel.

Randy Lawrence prepares to fix the rust damage typically found in the fenders of all types of cars. This example happens to be a '57 Ford, but the procedure he used is applicable to virtually any repair panel.

Although repair panels vary in size, shape, and location, the process used to install them is virtually the same. Generally repair panels will be larger than the area being replaced, which allows the installer to cut out the rust completely and end up with solid material to weld the replacement to. Although repair panels are sometimes butt-welded to the surrounding metal, flanging--or putting a step in one edge so they overlap--makes the process easier. Once the panel is positioned correctly it's tack-welded in place, then, to prevent warping the panels, the spaces between the tacks are slowly welded solid.

After the welding is completed the next step is to grind the welds flat, and this is where many novices make mistakes. Always use a rigid disc so only the weld bead is ground away. A flexible disc will tend to follow the surface and may remove metal from areas adjacent to the weld, which is not what you want. And don't grind too long and hard in one spot; you can warp the metal and create thin spots. Once the welds are ground down, a flexible disc can be used to blend the area, but do not grind excessively, as it will remove precious metal. In some cases hammer and dolly work will be necessary to straighten a repaired area, and more often than not a skim coat of body filler will be required to get the area ready for paint.

We followed along as Randy Lawrence of Manny's Repair put an EMS patch panel in the front fender of Gary Long's '57 Ford. Check it out and see what it takes to go from rotten to redone.