Between 2002 and 2010, I watched along with many of you as Mopar Muscle Editor Randy Bolig built and tested Project Valiant Effort, Randy's brutally simple, refrigerator white 1967 Plymouth Valiant. As editor of Popular Hot Rodding, I always envied that little econobox Mopar for its bantamweight punch and affordable acquisition price. As a big fan of Valiant Effort, I'd ask Randy how it was coming along, and felt sadness when he eventually sold it after eight years without having drag tested it. We'll never know what the 414ci small-block with 519 hp could do for Chrysler's shortest wheelbase A-Body. Nevertheless, there's no arguing that a snotty little motor in a light, cost-effective platform is the way to go fast on the cheap.

In February of 2012, I decided to act. It was time PHR readers had a dose of how to do a Mopar, only this time we'd be going straight for the jugular right out of the gate—big motor, bombproof tranny and rear, a modern suspension and brakes, but a stealthy street appearance just like Mopar guys like. No Pro Touring stuff here—the Chrysler crowd digs the old school, so we rolled with the granny look. We wanted a Q-ship, a reference to the convoy freighters from WWII that were rigged with guns, depth charges, and torpedoes—but disguised to look like easy prey for German U-boats. We wanted something tame looking but with a knockout punch, and Bolig's Valiant Effort provided the perfect model for us. An extensive search of Craigslist in Southern California dug up the perfect Slant Six '68 Valiant. It was a running, driving car with almost no rust or damage, and we scored it for $2,800.

Over the course of 11 stories, we made some killer headway. Then at 9:15 a.m. on May 29, 2014, this editor's life changed. We got a phone call telling us that after 54 years of publication, Popular Hot Rodding was ceasing operation. On the bright side, I would get to run Mopar Muscle, and it was a no-brainer to bring the Valiant over for completion. We figure the project for being about halfway through, and Mopar Muscle readers can easily check out each of the earlier PHR stories by going to the website (PopularHotRodding.com) and catching up. The website will remain up indefinitely, along with 11 related videos on the PHR YouTube channel (YouTube.com/PopularHotRodding).

To get things jump-started in this issue, we decided to give you the crib notes from all prior stories on the '68 Valiant. We're also renaming the project "Violent Valiant," because that's what happens when you shoehorn a 657hp low-deck wedge into a 2,900-pound car with a 225mm cross-section tire! If it sounds like fun to you, hang on—we're going to turn those Coker repro redlines into huge clouds of billowing smoke! Here's what went down, and a quick preview for what stories are in the oven right now…

Weekend Rehab

Our little Valiant had spent the better part of a decade buried up to its axles in sand near Barstow, California, and it was in surprisingly good shape. Although the body was far from perfect, we felt the old repaint could benefit from a weekend resto using a little elbow grease, and some car care products from Mothers. A trip to Jeff Jeppesen of Classy Cars Auto Detailing in Huntington Beach, California, had the chalky old paint looking brand new, and you can see the results yourself in our lead photo at the front of our story. We also discarded the old 13-inch wheels and mounted some new Coker redline repros on 15-inch steel wheels with dog-dish hubcaps. Total outlay for the car, rehab, and new rolling stock: $4,300! Not bad for getting in the game quick and cheap.

Our dusty '68 Slant Six Valiant, just as we found it. Look at the story lead image to see how two days of elbow grease and some Mothers car care products would transform it.

First thing we did was upgrade the 13-inch rolling stock with 15-inch steelies and redline repros from Coker. We used adapter plates to temporarily make the 4.5-inch bolt circle wheels work on the 4-inch bolt-circle of the Valiant.

The Indy Maxx 500

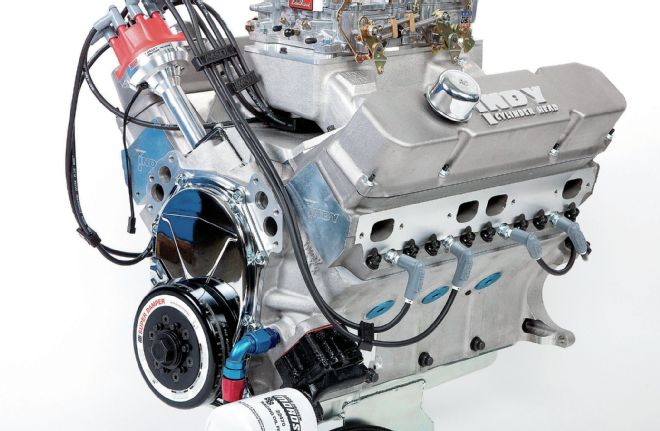

Meanwhile, we had our eyes set on the power prize. We thought about doing a budget 451ci low-deck wedge with a 400 block and a 440 crank, but after talking with the folks at Indy Cylinder Head, they convinced us that a low-deck wedge based on their ultralight aluminum Indy Maxx block would be the way to go. Outfitted with their new EZ-1 cylinder heads, an Eagle rotating assembly with Diamond forged pistons, a dual-quad Mod Man intake, T&D shaft rockers, dual-quad Edelbrock 500-cfm carbs, a solid cam and valvetrain from COMP, and a full complement of MSD ignition components, the 500ci Indy Maxx made 657 hp at 6,100 rpm and 662 lb-ft of torque at 4,500 rpm. We also liked that the little wedge weighed less than the Slant Six it would replace.

The all-aluminum 500ci low-deck wedge you can buy from Indy. Ours made 657 hp and 662 lb-ft of torque on pump gas with a friendly 10:1 compression ratio.

TCI TorqueFlite 727

Backing up the Indy Maxx 500 would be a beefcake A727 StreetFighter trans from TCI. TCI has been making solid transmissions for dragstrip and street use for decades, and they really know how to build a TorqueFlite right. In this case, it needed to take nearly 700 lb-ft of torque abuse without breaking a sweat, so we welcomed the strength from extra high gear clutches, upgraded forward drum clutches, Kevlar bands, upgraded servos, a shift- kitted valvebody, a TCI cast-aluminum pan, and a 3,000-stall TCI StreetFighter torque converter. Down the road, we're also hooking up a TCI Outlaw Shifter so we can precisely bang away shifts at our 6,100-rpm redline without any worry.

TCI builds some fantastic transmissions, and their experience with the Chrysler A727 runs deep. Our StreetFighter TCI box is upgraded in every area and is more than strong enough to handle the Indy 500 incher.

Strange S60 BuildUp

A common approach for A-Body fans is to swap out the stock 7¼-inch rear for the logical factory upgrade—the 8¾-inch rear. In fact, that's exactly what happened to Valiant Effort over 10 years ago, and that remains a great option for many gearheads. But the times—and the hardware—have changed. Rather than rehash old ground, we wanted to explore some new hardware coming out of the Strange Engineering stable, and their Dana-based S60 seemed like just the ticket. Not only is it more than up to the task of the Indy Maxx 500 wedge, it's relatively affordable, and contains all-new components. The S60 combines the brute strength of a Dana 60, with the serviceability of a drop-out, pumpkin-style axle, and Strange equipped ours with 35-spline axles, half-inch studs, 3.54 gears, a Detroit Truetrac diff, and Wilwood Dynalite disc brakes, for a total price just under $2,900.

John Kwas of Strange Engineering assembles our S60 rearend assembly with 3.54 gears, 35-spline axles, and a Truetrac limited-slip differential.

RMS AlterKtion

With the Indy Maxx 500 engine, TCI StreetFighter trans, and Strange S60 rear being built off-site, we didn't let grass grow under our feet. In the interim, we stripped away the Slant Six powerplant, 904 TorqueFlight, 7¼-inch rear, and all the suspension from front to rear. We shot the barren engine bay and trunk area with a quick coat of the factory Sunfire Yellow, rehabbed what remained of the undercarriage with some Eastwood Extreme Chassis Black, and ordered up an AlterKtion front suspension from Reilly Motorsports (RMS). Here, Reilly has done the unthinkable by completely re-engineering the Mopar torsion bar–based suspension with an adjustable coilover SLA design (using Viking shocks) that not only corrects flawed OEM geometry, but frees up loads of space for exhaust while lightening the whole thing. A power rack-and-pinion steering conversion is also part of the package, upping the ante in the handling department. We got the whole package installed in the lightning-quick time of four hours!

The RMS AlterKtion front suspension bolts up in just hours, giving multiple benefits of better geometry, more room for exhaust, adjustable shock damping, and responsive rack-and-pinion steering.

RMS Street-Lynx

Next on our punch list was to bring the rear suspension into the 20th century. Our Valiant's horse-and-buggy leaf-spring setup was fine for the low speeds and lumbering ride of the 1960s, but we wanted something with some modern handling capability, so we ordered Reilly Motorsports' Street-Lynx triangulated four-link rear with Viking adjustable coilovers. As we soon found, the rear Street-Lynx kit was even easier to install than the front AlterKtion system, and it would easily bring our handling up to contemporary levels without forcing us to ditch our entire unibody construction or abandon our period-correct rolling stock. The RMS gear would give us superb handling and cornering without going the pro touring route—an option that was further made possible by Wilwood's line of 11-inch Dynalite brake kits for 15-inch wheels.

When it comes to knowing Mopar brakes, it's hard to beat Wilwood. They offer more high-performance disc brake conversion kits for Mopar than any other company, and at a regular-guy price too. Our front 11-inch four-piston Dynalite kit cost around $700.

Wilwood Brakes

When it comes to brakes for anything Mopar, Wilwood has everybody covered. Those guys service all brands of muscle cars, but their special fondness for Chryslers really shows in their catalog of Mopar goodies. For our Mustang II-based AlterKtion spindles, Wilwood had exactly what we wanted in their Dynalite line, and when paired to a set of 11-inch discs all around, were a perfect fit for our 15-inch steelies from Coker. Of course, we pointed out in our original story that Wilwood also makes the Dynalite front kit for A-Body drum brake spindles like we had originally, and the installation procedure is nearly identical. Moreover, the entry cost for a front axle full of Wilwood Dynalite goodness is right around $700, which is a slam dunk relative to the hassle of cobbling together junkyard parts from a later-model '70s or '80s disc brake–equipped Chrysler. To help our installation along, we also picked up a Wilwood master cylinder and one of Reilly Motorsports' firewall master cylinder mounting kits.

Eliminating the leaf-spring rear suspension and converting to a triangulated four-link setup with RMS's Street-Lynx suspension can improve the ride quality and grip of any Mopar.

Be Cool Cooling Module

While it might sound like a broken record for us to put a Be Cool cooling module into a Mopar, the fact remains that very few companies support the Mopar cooling market like Be Cool, and Chrysler A-Bodies in particular. With a 500ci wedge capable of converting gasoline into heat at the rate of nearly a gallon and a half per minute (at full throttle), you need strong equipment for shedding all that thermal energy. For our Valiant, we used a 1,000hp Classic direct fit module (PN 62198, $839.99 from Summit) to get the job done. One thing to consider though is that this large of a system does require cutting the radiator core support and engine bay pinch welds—so it's not a kit for the tweaky geeky numbers matching guy. In the overall scheme of things, our Slant Six A-Body is unremarkable, so we had no problem making the necessary sheetmetal cuts in order to gain all that cooling.

Big horsepower means having big cooling system needs. Here, we fit the Violent Valiant for a Be Cool 1,000hp direct-fit cooling module.

US Car Tool Subframe Connectors

US Car Tool sells their chassis-hugging weld-in subframe connectors through Reilly Motorsports ($199), and they are the perfect solution for tying together the front and rear suspension elements of a lightweight unibody car like our Valiant. These rugged rectangular box channels attach to the front and rear framerails, and we welded them in with one of the nicest and easiest DIY welders we've ever had the pleasure of using—Miller Electric's voltage-sensing Millermatic 211 with Autoset. The US Car Tool subframe connectors are contoured to follow the floor's shape, and with only minimal grinding can be made to fit the underside of any A-, B-, or E-Body with ease. The added rigidity they provide easily restores the shortfall in chassis stiffness between unibodies and full-frame cars, and then some. A series of stitch welds joining the connectors to the floorpan makes the arrangement even more robust.

Weld-in subframe connectors like those from US Car Tool are some of the best bang for the buck when it comes to ride quality and handling. We installed ours using a Millermatic 211 MIG welder.

Aeromotive Fuel System

When it comes to sufficiently fueling a nearly 700hp motor, there are few easy choices, and most of them are expensive ones. At this power level, fuel cells, sumps, and loads of custom fabrication are the norm, but two years ago, Aeromotive came to the rescue with a time and money saving alternative. Called the Phantom Stealth system (PN 18688, $538 street price), the Aeromotive kit converts a new, factory-replacement fuel tank (ours was from Tanks Inc., $150), to a sumped, race fuel system capable of sustained fuel delivery for naturally aspirated engines up to 1,000 hp. And because of its clever shape-conforming foam sump, it can also withstand lateral g-loads well beyond what most cars can dish out. Armed with an Aeromotive A100 bypass regulator (PN 13204, $168.97) and an assortment of Russell Twist-Loc plumbing supplies, we made short work of the Valiant's fuel system while retaining a stock look and easy trunk access to the Aeromotive Phantom 340 fuel pump.

When going big on the horsepower, it raises the bar in every system on the car, including fuel delivery. Aeromotive hit a home run with their Phantom Stealth system, allowing us to convert a stock fuel tank to handle the big Indy wedge.

Inland Empire Driveshaft

Right about this time, PHRcame grinding to a halt, but not until after we had the Valiant measured for a custom driveshaft at Inland Empire Driveline Services. IEDLS specializes in custom high-performance driveshafts, and once you tour their facility and see the specialized equipment and experience the unique skill set required to build serious 'shafts, you'll know why they are so good. Our Valiant, of course, could not reuse the stock driveshaft from the original 904 TorqueFlite and 7¼-inch rear, its thin wall, small-diameter tubing notwithstanding. We needed something with enough balls to handle the Indy motor's monstrous twist, but that also had the balance and finesse to run smooth and silky on the Interstate. For that reason, we had IEDLS measure and then build us a stout steel drive tube equipped with the necessary 1350 yoke couplings. Not wanting to waste any time with the Valiant, we ran this story in the previous issue, marking our Valiant's first mention in Mopar Muscle!

The experts at Inland Empire Driveline Service know how to build a bitchin driveshaft that will handle the twist while performing vibration-free on the highway. If you're local in SoCal, they'll even come to you to measure your car at no extra charge.

TTI Headers & Exhaust

Here's where we start getting into a preview of what you're going to see in the coming months here at Mopar Muscle, and if you're curious, you can already check out a pair of cool videos on the installation of TTI headers and exhaust, as well as a deep-dive tour of the TTI production facility in Corona, California. (Check them out on the video page of PopularHotRodding.com.) Without giving away the ending, the thing that prompted this installment was the confluence of several events: in choosing Indy's EZ-1 cylinder head with a stock-location exhaust port, and in building the motor's power level with the need for so much exhaust flow, mentioning also the fact that fenderwell headers were not an option for us, we inadvertently put ourselves in the position of needing a header that hadn't yet been invented. Namely, a long-tube header with a minimum primary diameter of 2 inches and an exhaust port in the stock location. And they needed to stay out of the fenderwells in order to keep our fullsized front tires. One final demand: The primary tubes needed to clear the thicker Indy Maxx block's cross-bolted mains. When most other header manufacturers would've thrown in the towel with those demands, Sam Davis and the crew at Tubular Technologies Inc. (TTI) built the perfect set of ceramic-coated headers and companion dual exhaust—and you can actually buy them today! We'll have that to you next month, so stay tuned.

Next month, we'll show you what TTI has in the way of long-tube headers and exhaust for our 500ci low-deck wedge, A-Body chassis, and AlterKtion suspension.

Speedway Motors Battery Relocation

Shortly after TTI saved our bacon in the exhaust department, we moved the Violent Valiant to Motech Performance (Murrieta, California), which is one of the top Mopar specialty shops in Southern California. Proprietor Jason Muckala took our A-Body in to help ready the Valiant for its first street appearance, and he'll be doing a bunch of punch list fix-it items, including a cool story on relocating the battery to the trunk using a complement of items from the race car and hot rod experts at Speedway Motors. Curious about how that went down and can't wait for the story? Head over to MoparMuscle Magazine.com and check out the 20-minute video.

Beyond that, we'll show you how Jason Muckala and the Mopar experts at Motech Performance in Murrieta, California, installed our new Odyssey battery in the trunk using parts from Speedway Motors.

We're also renaming the project ‘Violent Valiant,' because that's what happens when you shoehorn a 657hp low-deck wedge into a 2,900-pound car…

We have renamed our Valiant "Violent Valiant," and made some custom OE-look fender badges for the time when we repaint it. If you see these badges on a Sunfire Yellow Valiant, look out!