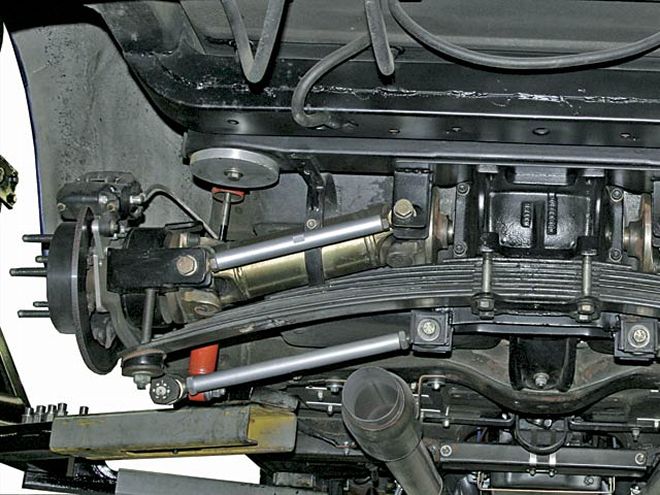

Tom's Diffs' stout 12-bolt gears and beefed IRS give old Corvettes new life in today's street car drags. Gordon and Mike Sakai campaign two hard-running Stingrays in the left coast's PSCA Limited Street class. Gordon's blue '65 fastback, shown here up the kilt, puts 1,000 hp through Tom's IRS, courtesy of a 406 and nitrous.

Tom's Diffs' stout 12-bolt gears and beefed IRS give old Corvettes new life in today's street car drags. Gordon and Mike Sakai campaign two hard-running Stingrays in the left coast's PSCA Limited Street class. Gordon's blue '65 fastback, shown here up the kilt, puts 1,000 hp through Tom's IRS, courtesy of a 406 and nitrous.

Old Corvettes were stout under the hood-who can forget the awesome Tri-power big-blocks, 12.5:1 L88s, or 454 torque-monsters? In their day, the old Vettes were a force to be reckoned with on the road course, but the drags were a different story; the Vette was literally a pain in the rear. Excessive camber changes meant that big power and even minimal traction led to vicious wheelhop, soon followed by six broken U-joints and pieces of halfshafts littering the starting line. If the halfshafts somehow survived, the pint-size 8.2-inch ring gear was more apt to lunch than launch. And even if you could make all those parts live, the Vette IRS was still persona non grata at the drags for 10.99-and-quicker cars because there was nothing to contain the drive axles and halfshafts if they failed. Sure, you see a competitive Vette from time to time, but it's probably running a conventional solid rearend and four-link that is far from a bolt-in. But that's about to change.

With the growing popularity of street car drags and really quick dual-purpose machines, there are a lot of Vette owners who want to get in on the action without the butchery of a solid axle swap. With a short 98-inch wheelbase and lots of engine setback (the front of even a big-block is behind the A-arms), a Corvette could be very competitive. We even saw a few fast IRS-equipped Vettes at the Pump Gas Drags, which provided the impetus for this story.

Enter Tom's Differentials, long-time Chevy 12-bolt rearend and Eaton Posi specialist. Years ago, Tom's figured out how to squeeze a 12-bolt ring-and-pinion and Eaton Posi case into the stock Vette IRS housing, but that was only half the battle. Tom's realized that making the conversion practical and legal meant addressing the entire rear suspension linkage and drive system. Eventually, the company perfected a complete-and virtually bolt-in-setup that utilizes huge, oversized U-joints, halfshafts, and inner and outer drive-axles. Tom's also modified the suspension geometry to minimize camber change. Finally, a safety retention kit consisting of loops and upper retaining links was developed to contain the drive components in the event of failure.

The result is a fully NHRA-certified suspension that is virtually bulletproof and has already powered 1,200hp, nitrous-equipped Corvettes to sub-8-second e.t.'s. In short, "IRS"-at least as it applies to Corvettes-is no longer a dirty word. Read on for a complete audit of Tom's itemized IRS deductions.

12-Bolt Conversion

The first step in strengthening the IRS-stuffing 12-bolt gears into the stock rearend housing-is arguably the hardest part of the entire modification process. It's not easy squeezing an 87⁄8-inch-od 12-bolt ring gear and all the other oversized parts into a housing originally designed to accept only 8.2-inch ring gears. Making everything fit requires modifying the housing, the housing cover, and even the gears themselves to gain the necessary clearance. Even so, at present the conversion is restricted to four-series cases (3.90-and-up gear ratios). Special aftermarket thin-flange 3.73:1 gears designed for the four-series case also work. Expect an all-new Tom's third member casting later this year that'll accept three-series Posi cases and gears.

Properly retained by a companion flange and with proper suspension geometry established, the stock Vette IRS 1350-series U-joint (left) has proven adequate through 600 hp. Need more? The 1480-series (right) is at least twice as strong. Even stick-shift cars have never broken one. Dedicated halfshafts, flanges, and axles are required when using 1480s.

Properly retained by a companion flange and with proper suspension geometry established, the stock Vette IRS 1350-series U-joint (left) has proven adequate through 600 hp. Need more? The 1480-series (right) is at least twice as strong. Even stick-shift cars have never broken one. Dedicated halfshafts, flanges, and axles are required when using 1480s.

Drive Axles and Shafts

Gearing up is only the beginning. Now that the third member is secure, all that torque must be transferred through drive axles, halfshafts, and U-joints. While the stock 1350-series U-joints are fairly adequate with correct suspension geometry, the drive axles are marginal, and as for the halfshafts, fergetaboutit-even an 11-second car will pretzel the stockers.

Tom's offers beefier U-joints, stout 1541 forged-steel drive axles and fatter 31⁄2 inch-od thick-wall steel or aluminum halfshafts (the best stockers introduced in the '70s were only 3-inch od). The stock inner axles have notoriously poor U-joint support. Most of them retain the U-joint using a flimsy U-bolt, but the stock big-block inner axles that use a U-joint strap retained by straight capscrews are only marginally better. Either way, only a thin Truarc keeps the axle from falling out of the housing. Ouch! Tom's axles use beefy C-clip retention and mate with big truck longitudinal driveshaft U-joint companion flanges that retain the U-joint with a press-fit and internal clips. Corresponding differential side gears and a grooved Posi-case mounting flange are needed to use the C-clip axles.

Suspension Mods

As with any rear suspension, the goal is to establish and maintain the maximum tire contact patch on the ground at all times. When correctly set up, the Corvette IRS gives the chassis tuner more flexibility in achieving this than does a solid axle. The key is minimizing camber change under running conditions through the full range of suspension travel, which ensures that the tires remain square with the pavement. The car should be set up so that at racing weight (with driver and gas) and at ride height, the rear camber control rods and halfshafts are parallel to the ground as well as to each other, and at the same time the tire patch is perpendicular to the pavement.

Simultaneously achieving these conditions mandates ride-height alterations, dropping the camber-control mounting bracket, replacing the flex-prone and hard-to-adjust stock eccentric camber rods with beefy tubular rods and rod ends, and installing custom, thick-wall, fully-welded trailing arms that are offset for wide tire clearance. Careful attention must also be paid to spring-rate selection, the length of the transverse spring itself, and the shock-absorber mounting position. A fairly stiff spring is used to prevent the suspension from porpoising, with the exact rate varying per application. The spring is about 2 inches shorter overall but with an additional leaf.

Safety and Structural Integrity

Beefing up the IRS to make it the torque of the town would be a futile undertaking if the system couldn't be made legal for NHRA competition. So Tom's developed a safety-retention kit to contain the IRS driveline to fully meet NHRA's demands. Safety loops similar to those used to retain a longitudinal driveshaft keep the halfshafts from pogo-sticking, while new upper links prevent the wheels from tilting over in the event the shafts do break. Think of it as the IRS equivalent of a solid axle's C-clip eliminator kit. And while not strictly required for NHRA competition, additional frame reinforcement as shown in the photos also comes highly recommended. Finally, if the car goes faster, it has to stop quicker, so there's also a Wilwood brake upgrade available.