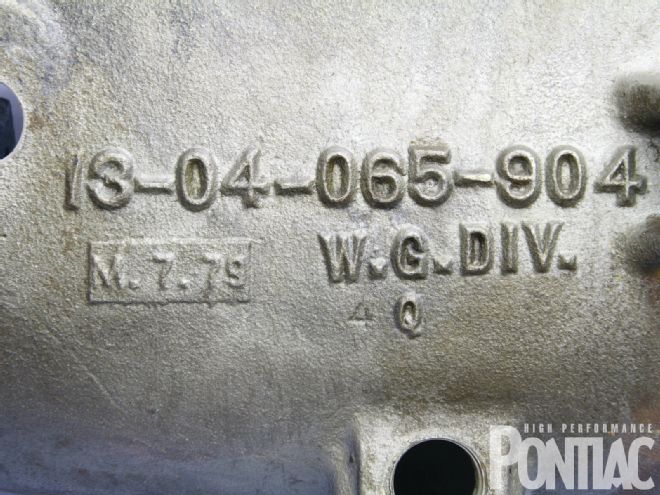

General Motors used a wide array of manual transmissions in its vehicles over the years, but the four-speed gearboxes from Muncie and Borg-Warner are undoubtedly the most popular. The Muncie four-speeds have a distinct reputation for strength and durability, but the second-design T10 developed by Borg-Warner in the ’70s, which is often referred to as the Super T10, is nearly as durable as any regular-production Muncie. It was the OE transmission in many Pontiacs from mid-year ’74 up into the ’80s. The sheer number of Super T10s produced during that era, and the fact that they are still produced today, makes used examples an affordable option for virtually any project.

So how can you improve the performance and reliability of your Pontiac’s Super T10? Follow along as we provide a number of ideas to help accomplish exactly that, and you might be surprised to find that not all are in the transmission!

1) High Quality Rebuild Kit

There are a number of manual transmission rebuild kits available today, and the quality of the components they include can range from very poor to very good. While price is generally indicative of the overall quality of a particular kit, knowing exactly what it contains is equally important.

A basic kit will include main-case bearings, gaskets, and seals. A better kit may also include new captured roller bearings, needle bearings, brass synchronizer rings, and snap rings and washers. The most complete kit might include such components as the cluster gear shaft, synchronizer keys and springs, and a case-extension bushing. Beware of inferior kits that are on the market, however. Not all of those available today include OEM-quality components.

This basic Super T10 rebuild kit, which features high-quality components, was sourced from our local transmission-supply parts store. It retails for about $125 and includes everything necessary to rebuild a transmission that’s otherwise in good working order. (The included gaskets are not shown.)

This basic Super T10 rebuild kit, which features high-quality components, was sourced from our local transmission-supply parts store. It retails for about $125 and includes everything necessary to rebuild a transmission that’s otherwise in good working order. (The included gaskets are not shown.)

You should purchase your Super T10 rebuild kit from a reputable transmission rebuilder or transmission-parts supply store. As opposed to simply ordering a kit online, it may be worthwhile to speak with a company technician to determine what your particular transmission may need. The overall condition of the Super T10 you’re rebuilding will determine exactly what’s required, but a quality kit with the right pieces will go a long way toward keeping your four-speed operating reliably for many years to come.

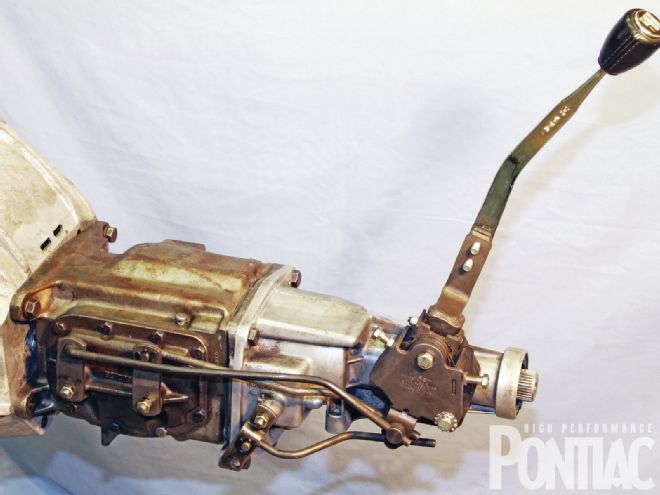

2) New High-Quality Gears

New OE-quality stock-replacement gears for the Super T10 are readily available from many sources, including your local transmission supply store. Not to be confused with the high-nickel 9310-steel gears produced for the Power Brute Super T10, which are no longer available, these stock replacements are constructed of 8620 steel, just like the originals. Expect to spend somewhere around $100 for each individual gear and about $200 for the cluster.

New OE-quality stock-replacement gears for the Super T10 are readily available from many sources, including your local transmission supply store. Not to be confused with the high-nickel 9310-steel gears produced for the Power Brute Super T10, which are no longer available, these stock replacements are constructed of 8620 steel, just like the originals. Expect to spend somewhere around $100 for each individual gear and about $200 for the cluster.

The gears of Borg-Warner’s regular production Super T10 were constructed of 8620-alloy steel—an affordable material that is quite durable. As gear ratios increased, so did the number of teeth on the main and cluster gears, and that reduced the maximum torque capacity of the entire transmission.

Not so coincidentally, the Super T10 that Pontiac specified for its high-torque 400 and 455s was a close-ratio unit with a First-gear ratio of 2.43:1, which happens to boast of the greatest torque capacity rating of any Super T10. While complete gear failure of a 2.43:1 transmission in a stock-type application is relatively uncommon, there’s no telling just how much abuse a particular transmission has been subjected to over the years.

Borg-Warner offered its Super T10 four-speed manual transmission with a number of different gear ratios, and the easiest way to identify them is by the number of machined grooves on the input shaft. Pontiac specified a close-ratio gearbox with a 2.43:1 First-gear ratio for its 400 and 455 engines, and it will have two rings on its input shaft.

Borg-Warner offered its Super T10 four-speed manual transmission with a number of different gear ratios, and the easiest way to identify them is by the number of machined grooves on the input shaft. Pontiac specified a close-ratio gearbox with a 2.43:1 First-gear ratio for its 400 and 455 engines, and it will have two rings on its input shaft.

If any gear looks as if it isn’t worth reusing, it may be best to opt for a new stock-replacement rather than take chances reusing a questionable original. Readily available from most any transmission rebuilder or transmission-parts supply store, the money spent on one or several new gears is relatively cheap when you consider that any such failure will require complete transmission disassembly, and, quite possibly, a long list of new parts.

3) Cast-Iron Bearing Support

The bearing-support is sandwiched between the main case and the extension, and it’s often called a midplate. It houses the large roller bearing that supports the main shaft, and the constant jerking motion that occurs during hard shifts can compromise the integrity of the cast-aluminum original. Used originals like this are available, but S-K Speed in Lindenhurst, New York, offers an exact reproduction for less than $100.

The bearing-support is sandwiched between the main case and the extension, and it’s often called a midplate. It houses the large roller bearing that supports the main shaft, and the constant jerking motion that occurs during hard shifts can compromise the integrity of the cast-aluminum original. Used originals like this are available, but S-K Speed in Lindenhurst, New York, offers an exact reproduction for less than $100.

The Muncie and Borg-Warner four-speeds were comprised of a main-case, bearing-support, and case-extension. As its name implies, the bearing-support is a cast plate that houses the large roller bearing, which supports the entire main shaft, and the bearing is retained by a snap ring on either end. Located between the main case and extension, the bearing-support is often called a mid-plate.

On production transmissions, the bearing-support was constructed of cast-aluminum, and the material proved rigid enough to endure the forward and rearward thrust that the main shaft sees during normal operation. The hard and quick shifts a manual transmission sees in high-performance applications can take its toll on the bearing-support, however, and that can distort the bearing flange, or even cause it to fatigue and crack, in extreme cases.

What happens when your attempt to channel too much power through a regular-production Super T10? The main case can flex, which prevents the gears from meshing properly, and that can lead to irreparable gear failure. Our modified 455 sheered two teeth from the cluster gear, and that damaged the opposing gears of the main shaft. We hoped to prevent this from happening again with some specific modifications.

What happens when your attempt to channel too much power through a regular-production Super T10? The main case can flex, which prevents the gears from meshing properly, and that can lead to irreparable gear failure. Our modified 455 sheered two teeth from the cluster gear, and that damaged the opposing gears of the main shaft. We hoped to prevent this from happening again with some specific modifications.

Borg-Warner developed a cast-iron bearing-support to further improve the reliability of certain production transmissions around 1980, and it has been a popular hobbyist upgrade since. As the supply of original cast-iron units diminished, a few different companies began producing their own reproductions, and S-K Speed is among them. Though its inventory is presently depleted, we’re told that more should be available in late-2011. If you can’t locate a used original, the new reproduction will install without any modifications.

4) Cast-Iron Main Case

Borg-Warner developed a cast nodular-iron case for its aftermarket Power Brute Super T10 to improve strength and rigidity, while regular-production Super T10s used an otherwise identical cast-aluminum case. During the ’80s, Borg-Warner began specifying the iron case for some of its production units. Used nodular-iron cases are sometimes available separately, but you may have to purchase a complete transmission just to get one. A new high-nickel main case is another option.

Borg-Warner developed a cast nodular-iron case for its aftermarket Power Brute Super T10 to improve strength and rigidity, while regular-production Super T10s used an otherwise identical cast-aluminum case. During the ’80s, Borg-Warner began specifying the iron case for some of its production units. Used nodular-iron cases are sometimes available separately, but you may have to purchase a complete transmission just to get one. A new high-nickel main case is another option.

Main-case flexing may be the root cause behind most manual transmission gear failures. The high-torque load associated with full-throttle acceleration can cause the main case to flex. While a certain degree of flex is normal, excessive flex can affect the alignment of the main-shaft gears and the cluster, and that can relocate the gear’s torque load from the center of each tooth to the tip, making it susceptible to failure.

The regular-production Super T10 featured a lightweight No. 903 cast-aluminum main case, and failures were relatively uncommon. As years progressed, new lower-ratio gear sets were developed, and by 1980, a First-gear ratio of 3.42:1 was used with 301ci Pontiac and 305ci Chevy engines. The number of gear teeth required to achieve that ratio made the gears vulnerable. When combined with the amount of main-case flex that was once considered normal, gear failure was common.

To limit the number of warranty claims, Borg-Warner incorporated its heavy-duty No. 904 cast nodular-iron main case from the aftermarket Power Brute Super T10 into some of its regular-production units around 1980. The iron main case helped curb warranty-claim failures, but once the low-ratio transmissions were removed from their original vehicles and used as replacements in various other applications, the real weakness of the 3.42:1 gear set began showing up.

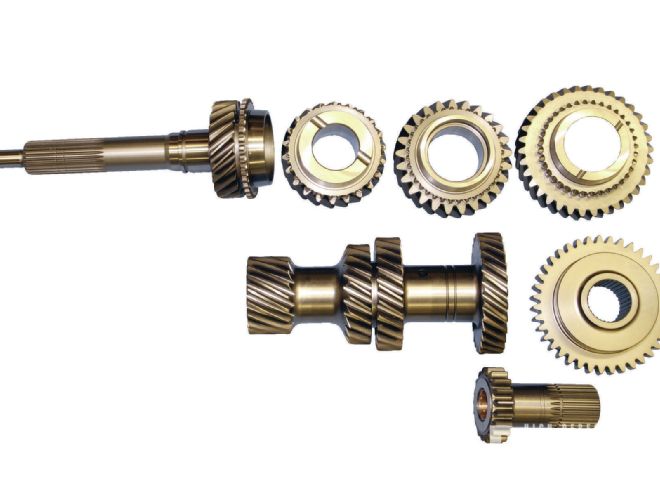

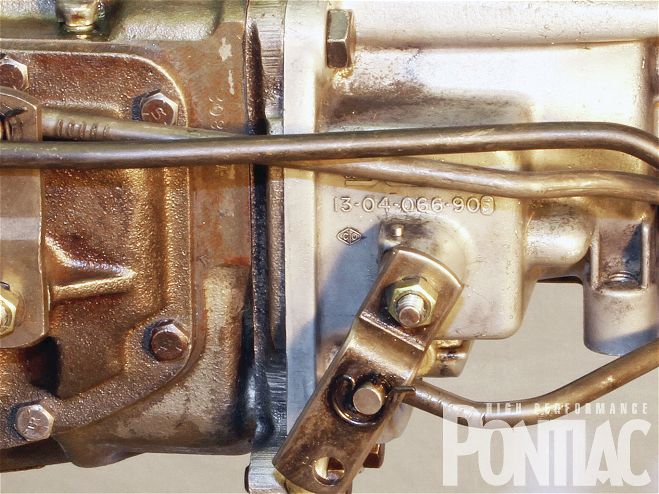

The Borg-Warner main cases are typically identified by the last three digits of the complete part number, which is found on the left-hand side of the housing. No. 903 is the regular-production cast-aluminum case unit, while No. 904 refers to the desirable cast-iron units.

The Borg-Warner main cases are typically identified by the last three digits of the complete part number, which is found on the left-hand side of the housing. No. 903 is the regular-production cast-aluminum case unit, while No. 904 refers to the desirable cast-iron units.

When building a Super T10 for use with a modern high-performance engine and retaining the original numbers-matching main case isn’t a concern, a No. 904 nodular-iron main-case is highly recommended. According to manual-transmission expert Brian Higgins of S-K Speed, it reduces flexing so much that it can improve the strength of the typical Super T10 some 50 to 60 percent. The price of a used No. 904 main case can range from $150 to $500, depending upon how badly you need it. Persistence and patience can reward you with one at a more reasonable cost.

Borg-Warner also developed an aftermarket high-nickel T10 main case that was available only as a separate item. Said to nearly double the capacity of a typical transmission, the high-nickel case is extremely rare. Fortunately, S-K Speed offers a proprietary reproduction that contains so much nickel content, it’s almost considered cast-steel. It retails for $400 and is an excellent choice for any Super T10 that will be used behind a powerful engine.

5) Flywheel

Centerforce offers two billet-steel flywheels for Pontiac applications, and both are drilled and tapped to accept the 10.4- and 11-inch clutch disc and pressure plate assemblies that Pontiac commonly used. No. 700600 features a 2.75-inch-diameter crankshaft register for pre-’75 engines, while No. 700610 features a 2.49-inch-diameter register for later engines. Retailing for around $350, it’s a worthwhile expense that can restore clutch geometry, improve shift quality, and help prevent flywheel failure too.

Centerforce offers two billet-steel flywheels for Pontiac applications, and both are drilled and tapped to accept the 10.4- and 11-inch clutch disc and pressure plate assemblies that Pontiac commonly used. No. 700600 features a 2.75-inch-diameter crankshaft register for pre-’75 engines, while No. 700610 features a 2.49-inch-diameter register for later engines. Retailing for around $350, it’s a worthwhile expense that can restore clutch geometry, improve shift quality, and help prevent flywheel failure too.

A flywheel stores kinetic (rotational) energy and helps produce a smooth and stable idle. Depending upon engine displacement and/or the model year, Pontiac used different diameter clutch discs, and the cast-iron flywheel was drilled and tapped for the corresponding pressure-plate assembly. The flywheel register on a Pontiac crankshaft measured 2.75 inches through ’75, at which point it was resized to 2.49 inches. These characteristics imply that original Pontiac flywheels may not easily interchange without modification.

Pontiac’s cast-iron flywheel was rarely problematic. The heat-related stress cracks and minor surface warping that occurs during normal operation typically requires little more than surface machining, but with the newest Pontiac flywheel more than 30 years old, there’s no telling how many times a particular unit has been machined over the years. An excessively machined flywheel could alter normal clutch operation and that can negatively affect the way your Super T10 shifts at a particular speed.

Deep stress cracks are a more serious issue. Some may be so deep they cannot be completely machined away, and that could compromise a cast-iron flywheel’s ability to withstand the abuse associated with a high-performance engine, resulting in complete failure. It could send fragmented portions of the flywheel through the floorboard, inflicting serious personal injury.

Centerforce offers a billet-steel flywheel that is a direct replacement for the stock Pontiac piece. Not only can it restore proper clutch linkage geometry and improve the shifting performance, its billet-steel construction makes it significantly stronger than any cast original, and that’s something that might provide you with peace of mind the next time you row through the gears.

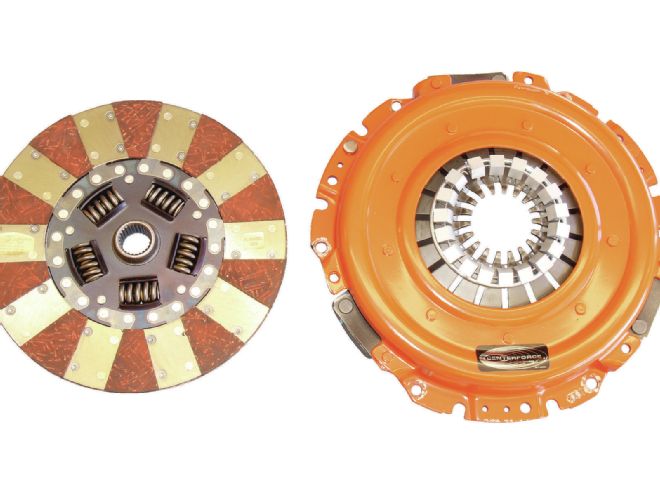

6) Clutch Disc and Pressure Plate Assembly

The Dual Friction clutch kit from Centerforce provides excellent clamping force with low pedal effort. Available in 10.4- and 11-inch-diameter discs and with 10- or 26-spline hubs, Centerforce certainly has one to fit your application. You’ll never be able to tell from the driver’s seat that your Pontiac is equipped with a high-performance clutch assembly, but the Centerforce unit won’t let you down when you count on it most. The Dual Friction kit retails for about $350.

The Dual Friction clutch kit from Centerforce provides excellent clamping force with low pedal effort. Available in 10.4- and 11-inch-diameter discs and with 10- or 26-spline hubs, Centerforce certainly has one to fit your application. You’ll never be able to tell from the driver’s seat that your Pontiac is equipped with a high-performance clutch assembly, but the Centerforce unit won’t let you down when you count on it most. The Dual Friction kit retails for about $350.

A clutch disc and pressure-plate assembly acts as a mechanical coupling device that transmits engine power to a manual transmission. The pressure plate spring forces the clutch disc against the flywheel, allowing power to flow through the transmission during normal operation. A pedal in the passenger compartment is connected to a linkage, that, when fully depressed, pushes on the pressure-plate springs, releasing the clutch disc so gear changes can be made.

The pressure-plate spring is mostly responsible for securely holding the clutch disc against the flywheel. In years past, the only way to eliminate clutch slippage in high-performance applications was to use a heavy pressure-plate spring. That often resulted in a clutch pedal that was so stiff that it was unmanageable for some drivers. In those instances, a lazy driver wouldn’t fully depress the clutch pedal, and that could cause excessive wear on the transmission synchronizers.

That’s not the case with the Centerforce Dual Friction clutch kit. The high-performance clutch kit combines a clutch lining constructed of premium materials and a series of special weights that surround the diaphragm spring on the pressure plate. As centrifugal action forces the weights outward at higher engine speeds, the weights apply additional pressure onto the clutch disc, preventing clutch slippage at high rpm. The driver is rewarded with a low-effort clutch pedal that allows for smooth and positive gear changes, and long-lasting synchronizers.

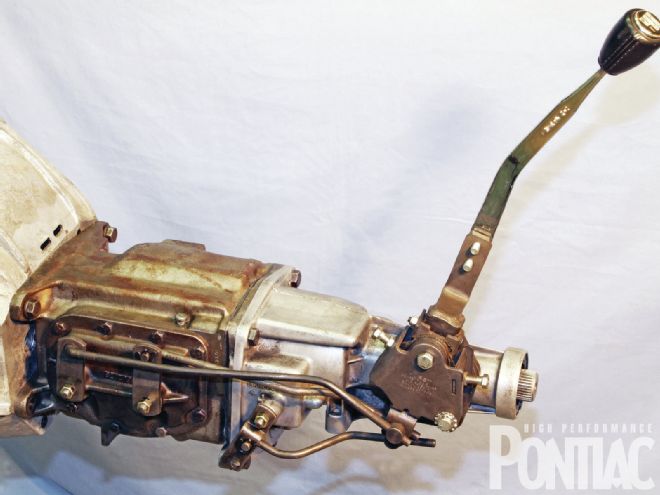

7) Hurst Competition Plus Shifter

Hurst Competition Plus shifters remain very popular and can dramatically improve the way a manual transmission shifts. Hurst offers a number of different shifter kits for various models, and its website will help you determine the correct kit for your application.

Hurst Competition Plus shifters remain very popular and can dramatically improve the way a manual transmission shifts. Hurst offers a number of different shifter kits for various models, and its website will help you determine the correct kit for your application.

The Hurst name is synonymous with performance, and its aftermarket shifters continue to be a popular upgrade with hobbyists looking to improve their transmissions’ shifting performance. Pontiac was one of the only manufacturers to include a factory-installed Hurst shifter in its performance models equipped with manual transmissions.

Even though the factory-installed Hurst units Pontiac used may have been better than the standard shifters used by others, they were somewhat compromised to meet a price point, and didn’t shift as smoothly as an authentic Competition Plus unit from Hurst.

The Competition Plus is a high-performance replacement that’s available for a wide range of vehicles and transmissions. It features a high-quality shifter mechanism with adjustable gear stops to prevent over-shifting the gears and a bolt-on chrome shifter handle.

The Competition Plus’ mechanical linkage has heat-treated components to maximize strength and durability.

The Competition Plus’ mechanical linkage has heat-treated components to maximize strength and durability.

The best-built transmission may never shift smoothly with a low-quality shifter assembly. If getting the most from your Super T10 is important, then a Competition Plus kit from Hurst Shifters may be what your Pontiac needs. The entire assembly retails for around $400, but you’ll consider it money well spent after the first shift.

8) Hurst Pit Pack

The Pit Pack kit from Hurst Shifters includes steel bushings that replace the nylon units included with the Competition Plus shifter. It provides positive shifts and resists the wear that can distort the nylon bushings during hard shifts.

The Pit Pack kit from Hurst Shifters includes steel bushings that replace the nylon units included with the Competition Plus shifter. It provides positive shifts and resists the wear that can distort the nylon bushings during hard shifts.

The Hurst Competition Plus shifter kit includes nylon bushings that fit between the shift-fork arms and linkages. They are designed to remove any slop between the components, and make shifts more positive. Hard shifts can distort the nylon bushings to the point that they cannot perform their intended task, and that can eventually lead to a less-positive feeling.

If you’ve purchased a Hurst Competition Plus shifter and plan on shifting your Super T10 hard, then a new Pit Pack bushing and spring kit from Hurst Shifters may be for you. The bushings are available in nylon to simply replaces the originals, or steel, which are designed to endure the punishment of hard shifts and provide a longer service life. Either kit retails for less than $10.

9) Gear Lube

Synthetic gear lube has gained a bad reputation from manual-transmission owners, as it has a tendency to excessively wear the brass synchronizer rings. Richmond Gear has developed its own proprietary 75W-90 full-synthetic gear lube specifically designed for manual transmissions that is supposed to prevent premature component wear and promote maximum performance and service life

Synthetic gear lube has gained a bad reputation from manual-transmission owners, as it has a tendency to excessively wear the brass synchronizer rings. Richmond Gear has developed its own proprietary 75W-90 full-synthetic gear lube specifically designed for manual transmissions that is supposed to prevent premature component wear and promote maximum performance and service life

There’s no question about it—synthetic lubricants are very popular. It’s believed that when compared to conventional lubricants, synthetics improve lubricity, and the resultant friction reduction can lower the operation temperature of a particular component. While there are certainly distinct advantages to that benefit, many hobbyists who have used synthetic gear lube in their vintage manual transmissions for an extended period have reported excessive synchronizer wear that ultimately requires complete replacement.

The belief is that the synthetic lubricant is simply too slick, and it doesn’t adhere to the critical internals that rely on a constant lubrication film for proper transmission operation. The technicians at Richmond Gear feel that’s only partially true, however. Many modern gear lubricants (whether conventional or synthetic) contain a friction modifier—an additive that thins the lube so the clutch plates within a limited-slip differential operate properly. In days past, the friction modifier was a specific additive, but it’s commonly included in today’s offerings, and it tends to compromise the synchronizer ring’s ability to perform its intended task.

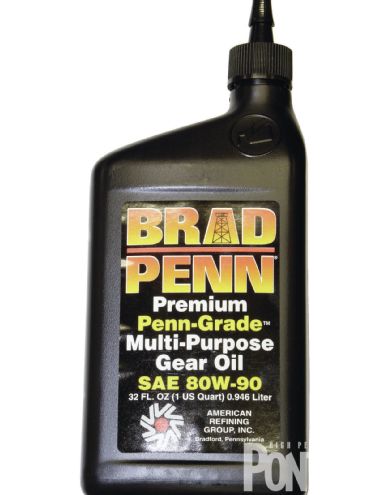

Many hobbyists prefer conventional gear lubricant to synthetic for their manual transmissions for its well-proven protection. Brad Penn Racing’s 80W-90 Multi-Purpose Gear Lube is an excellent choice for any vintage gearbox, and is one we recommend. It’s free of the friction modifiers that can compromise the synchronizer function that leads to excessive wear. Contact Brad Penn Racing to find its nearest retailer to you.

Many hobbyists prefer conventional gear lubricant to synthetic for their manual transmissions for its well-proven protection. Brad Penn Racing’s 80W-90 Multi-Purpose Gear Lube is an excellent choice for any vintage gearbox, and is one we recommend. It’s free of the friction modifiers that can compromise the synchronizer function that leads to excessive wear. Contact Brad Penn Racing to find its nearest retailer to you.

Richmond Gear has created its own synthetic gear lubricant specifically designed for use with manual transmissions. The high-quality 75W-90 lube contains no friction modifiers and it carries a GL-6 rating. According to the company, its testing has shown a normal operating temperature reduction of nearly 20 degrees when compared to conventional lubricants. No. TLUBE retails for about $15 per bottle and is available from most any mail order auto-parts retailer.

Even though synthetic lubricants are popular and a new option for manual transmissions is now available, anyone that’s had to tear down a newly rebuilt transmission only to replace excessively worn synchronizer rings because of synthetic gear lube may very well be convinced that conventional gear lubricant is the only choice for a vintage manual transmission.

If you’re looking for a conventional gear lubricant, Brad Penn Racing’s 80W-90 Multi-Purpose Gear Lube is a high-quality formula that offers maximum component protection and is free of any friction modifiers that could harm your transmission’s synchronizers.

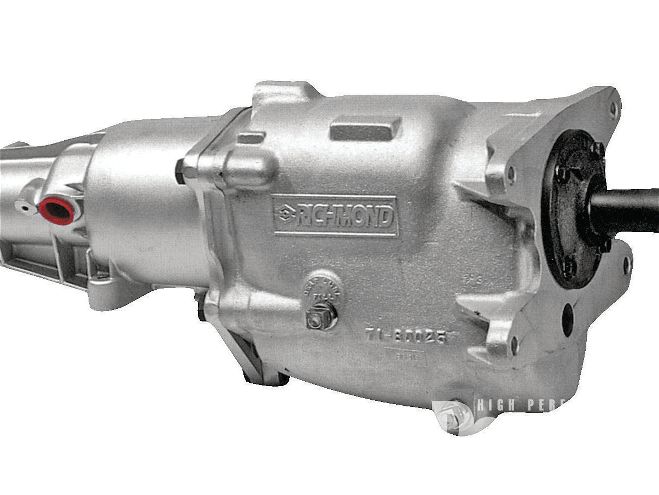

10) New Richmond Super T10

You’ve read all the ways that you can improve the performance and reliability of your existing Super T10, but what if you simply want a brand new OE-quality four-speed for your Pontiac and don’t see the need for a cast-iron case or bearing support?

Richmond Gear is a premier transmission supplier and presently produces the new Super T10. The original design worked so well that beyond the improved machining and finishing processes available today, it remains very much like what Borg-Warner originally designed. The modern Super T10 is available in a number of gear ratios, and each new unit is complete and ready to bolt in.

Richmond Gear is a premier transmission supplier and presently produces the new Super T10. The original design worked so well that beyond the improved machining and finishing processes available today, it remains very much like what Borg-Warner originally designed. The modern Super T10 is available in a number of gear ratios, and each new unit is complete and ready to bolt in.

Richmond Gear has the answer. It presently produces the Borg-Warner-designed Super T10 and it offers it in two distinct versions—the basic Super T10 and the Super T10 Plus. The new transmission contains all the design features of the original and fits and functions identically. The Super T10 Plus also includes a road-race-type synchronizer that’s more durable and better suited for performance driving

A number of different gear ratios are available for either Super T10. Richmond Gear technicians can help you determine the best ratio for your Pontiac if you don’t already have one in mind. Retailing for about $1,700, a new Super T10 will fit and function just like an original, and perform just as well. It can be considered an excellent alternative when attempting to salvage a well-used example!