When HPP teamed with GM Performance Parts (GMPP) and Classic Restorations to mate the new THM 4L85-E SuperMatic transmission to a built-to-the-hilt SD-455, we wanted to fully document the process. Thus previous issues covered in great depth the internal workings of the SuperMatic, along with the physical installation into a '74 Trans Am (Feb., Mar., and Apr. '10, or check online at highperformancepontiac.com).

To tune the SuperMatic to your Pontiac, put away the wrenches and take out the laptop.

To tune the SuperMatic to your Pontiac, put away the wrenches and take out the laptop.

The last installment was dedicated to the cooling and electronic controls that are required to integrate the SuperMatic with the traditional-but-modified Pontiac engine. The 455 in this T/A was also the subject of an in-depth engine build and dyno sessions (both engine and chassis) a few years ago, which included the testing of a new EFI system. The result is an electronic-fuel-injected SD T/A with a state-of-the-art microprocessor-controlled transmission-a vintage Pontiac with almost as many computer chips under the hood as an '09 model.

The SuperMatic possesses many virtues, such as the ability to withstand a huge amount of torque (685 lb-ft), along with an overdrive gear ratio (0.75:1). During our work with the SuperMatic, HPP had the opportunity to talk with Jayson Schwalm and John Boughner. Jayson was the lead calibration engineer on the OE installation of the 4L85-E; John was the calibration manager. They told us it was designed to pass the rigorous GM test of lasting 200,000 miles under a full torque load when connected to a Duramax Diesel in a GM van (a factory application for this transmission). They both said simultaneously that the 4L85-E passed with flying colors.

Jayson continued: "The lessons learned when designing, manufacturing, and calibrating the 4L85-E are responsible for GM's ability to offer a 100,000-mile powertrain warranty on all of its 2010 model cars and light-duty trucks. That warranty proves GM quality to the consumer and is not matched by any competitor in the marketplace right now." And the 4L85-E SuperMatic is even stronger.

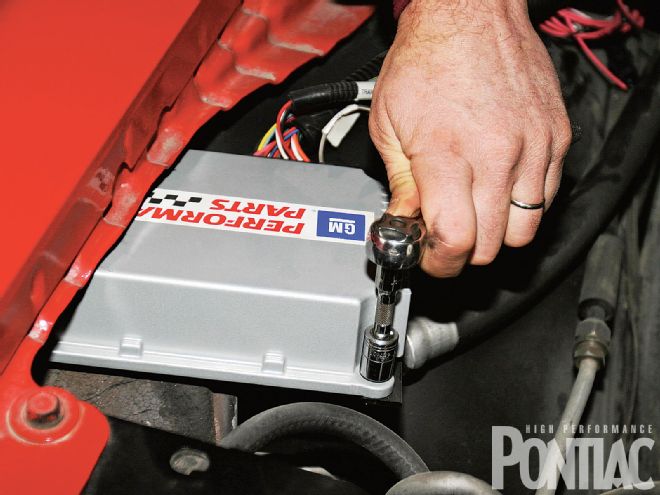

We securely mounted the TCU under the hood of the Firebird.

We securely mounted the TCU under the hood of the Firebird.

It's now time to explore the transmission's ability for end-user programming of almost every operating function, which is accomplished though the use of a laptop, dedicated software, and an interface cable that talks to the microprocessor in the TCU (transmission control unit). This transmission allows the shift strategy to be altered in the way a valvebody shift kit would, but with one big difference-it's done by the stroke of a keyboard with no wrenches required.

This exciting capability will allow you to completely tune the SuperMatic to your driving style, requirements, and the torque and horsepower of the engine in your Pontiac. No longer will you be forced to make compromises in shift quality and rpm point or feel, or be tethered to a transmission shop to try and get it the way you want it.

Thinking Like A Calibrator

Before we delve into the tuning points of the SuperMatic, a few things need to be established. The 4L85-E is still an automatic transmission. It does not operate through electronics. The dynamics of hydraulic fluid flow are still as relevant as in any self-shifter. Its valvebody with all of its pistons, springs, check balls, and calibrated orifices has been replaced by electronic solenoids. The transmission fluid still does the work, but instead of a traditional mechanical/hydraulic design, the SuperMatic is a hydraulic/mechanical/electronic system. Thus the torque converter, planetary gear set, and the like still operate in a similar fashion to a THM 350 or 400.

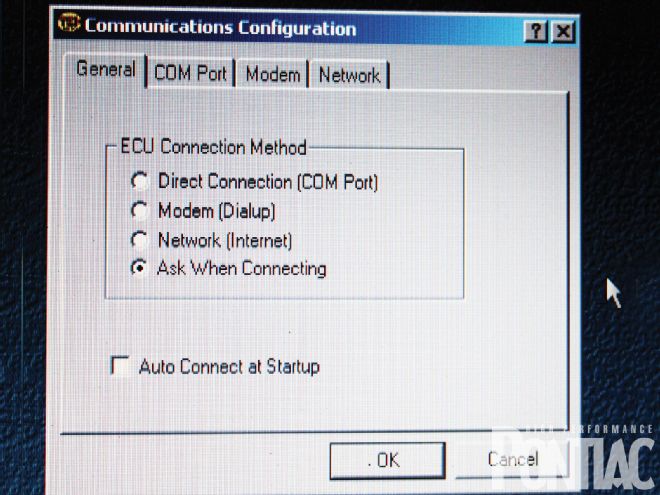

The calibration process begins by telling the TCU how you want it to communicate with the laptop.

The calibration process begins by telling the TCU how you want it to communicate with the laptop.

The benefit of the electronic controls is a finite and wider range of tuning than would be allowed with springs and check balls. When dealing with a strictly mechanical valvebody, whatever compromises necessary are often accepted. For example, the shift quality at light load may end up being too hard for your liking, but it's required for the proper amount of clutch pressure under full power.

Even the best transmission guru would often have to accept a comprimise in one operating range for the proper performance at the track. Though neck-snapping part-throttle shifts may seem cool at first, they are not desirable over the long haul. With the SuperMatic, that will no longer be the case, as you can have your cake and eat it too.

In addition, the SuperMatic comes with a complete calibration already in the TCU. GMPP calls it a default calibration, though in the proper engineering parlance it may be misleading to the hobbyist. A better term than "default" would be "generic." In most cases, the as-shipped calibration will work amazingly well with a high-torque Pontiac engine. As a matter of fact, our test T/A drove like a dream with the default strategy. Don't be misled into thinking that you need to be a combination of a computer and transmission engineer to enjoy the benefits of the SuperMatic, as that is not the case.

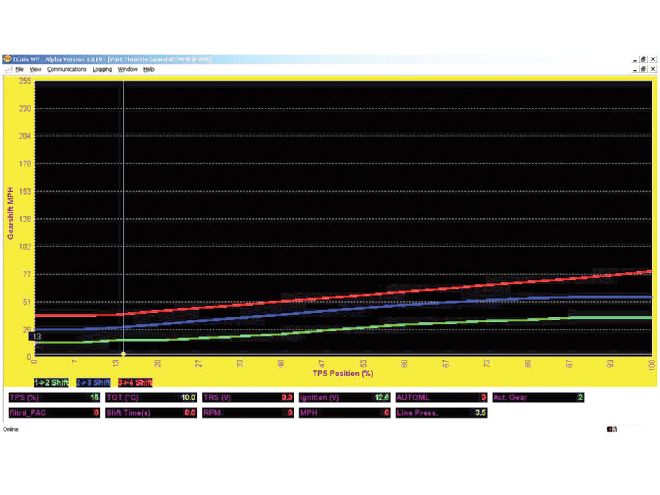

Many of the calibration screens are configured as an X-Y axis with dashboard data below the graph. Changes are made by moving the cursor and modifying the graph. This table adjusts the shift schedule as a function of throttle angle. An advanced algorithm analyzes throttle angle, vehicle speed, and engine rpm to time the shift.

Many of the calibration screens are configured as an X-Y axis with dashboard data below the graph. Changes are made by moving the cursor and modifying the graph. This table adjusts the shift schedule as a function of throttle angle. An advanced algorithm analyzes throttle angle, vehicle speed, and engine rpm to time the shift.

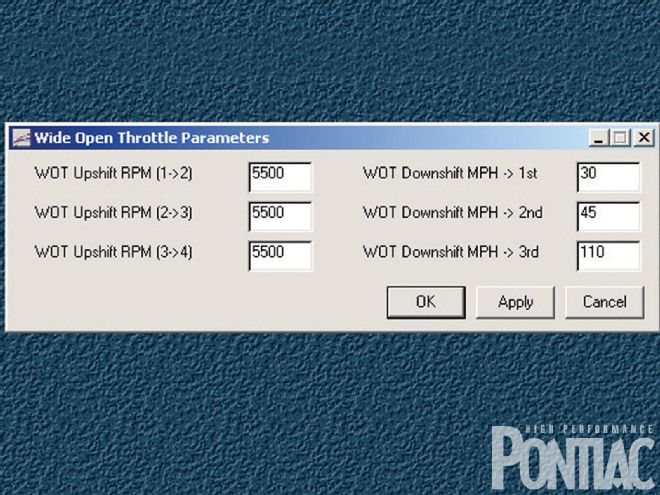

The WOT shift points will most likely need to be reset when the 4L85-E is bolted to a Pontiac, however. As shipped, the TCU has the shift occur at 6,400 rpm, a speed that is too high for most street/strip Pontiac engines that are torque-rather than rpm-biased. To change this value is no more complex than typing in the desired new engine speed.

Note that this primer is not meant to be a substitute to the manual supplied with the TCU. HPP's purpose is to touch on the highlights of the transmission's ability, not be an all-inclusive tuning guide. The SuperMatic control unit is a very sophisticated piece of equipment, and all literature must be thoroughly read and understood before any changes in the calibration are performed.

When performing a transmission calibration, it's imperative that the desired attributes be established. The transmission calibration is the cumulative effect of the engine torque at a given rpm; the torque converter stall rate, along with the engagement of the lock-up clutch (the 4L85-E is shipped with a lock-up torque converter with a stall speed of around 2,000 rpm); the weight of the vehicle; the final-drive gear ratio; and the tire diameter. These are the factors that GMPP cannot predetermine, since this transmission can be bolted to a multitude of applications.

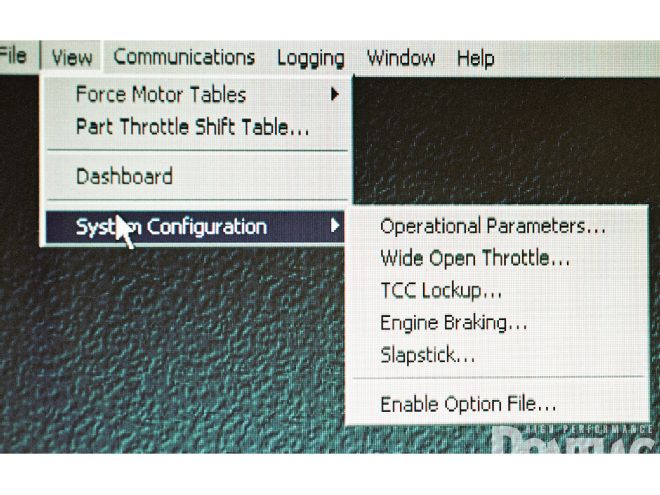

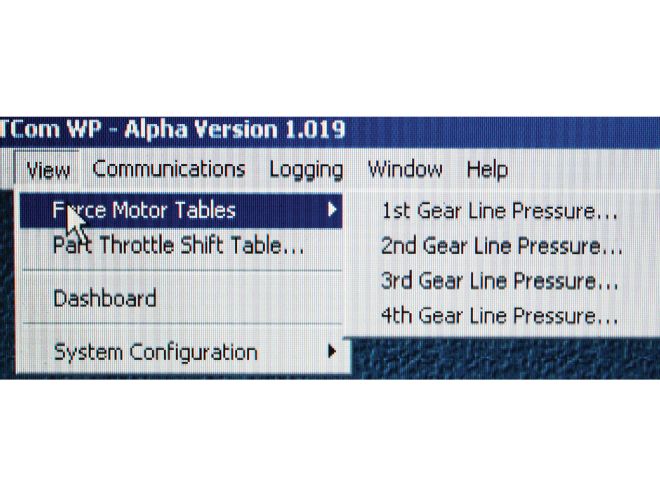

Windows-based software allows easy access to the different tuning tables.

Windows-based software allows easy access to the different tuning tables.

Ideal Transmission Shift Strategy

Under light load and normal driving, the transmission should shift into the next gear as soon as possible without lugging the engine. You don't want the shifts to be stacked one right after another without letting the vehicle gain speed and the engine build torque. Once rolling and the throttle pressure is steady along with the road speed, the Torque Converter Clutch "TCC" would then engage, eliminating any internal converter slippage.

The engagement of the TCC should be at an engine and road speed that will not evoke any lugging (sometimes called chugging) and allow the crankshaft rpm to respond to input from the throttle. The TCC should be engaged at a rate (this is the time for the clutch to apply and not the engine or road speed) as to not shock the drivetrain, yet not evoke excessive slippage, which would raise the transmission fluid temperature and increase wear.

During normal driving, the shift quality should be firm, but muted. The hydraulic pressure that must be created by the pump before the shift is accomplished controls this. Excessive pressure will shock the drivetrain and the vehicle occupants; too little pressure will allow the clutches to slip excessively during the gear change.

Force Motor Tables are where the shift line pressure is adjusted for each gear change. Higher line pressure creates a firmer shift.

Force Motor Tables are where the shift line pressure is adjusted for each gear change. Higher line pressure creates a firmer shift.

As the throttle is crowded (the engineering term for opened more), the transmission should respond by raising the line pressure for each shift, since the torque input to the gearbox will now be increased. The proper line pressure setting for a performance Pontiac will allow almost undetectable shifts under light load with no bog or hesitation between gear changes; then it should bark the tires on the One-Two gear change at WOT. The Two-Three and Three-Four gear change should be quick and very firm, using all of the torque the engine is producing.

The WOT gear changes should occur just before peak power is produced in the engine (about 100 to 200 rpm before) so that by the time the gear change is accomplished, the engine has reached its peak horsepower. (Make sure that your tach is accurate!) If the engine starts to nose over or goes flat before the gear change is complete, the WOT shift rpm will need to be lowered until the performance is seamless.

To accomplish all of this, the TCU offers a number of tables to alter the characteristics of the transmission shift strategy. Most tables are designed as an X and Y axis that will allow a multitude of tuning points. Some other tables are simply charts with values. The WOT shift table is this way and just needs to have an rpm entered. As with any calibration, it's going to be trial and error with the vehicle being driven under different operating conditions.

It is the author's opinion that a building-block approach should be taken when dialing in the calibration. The part-throttle and light-load tuning should be done first, and then the vehicle should be driven in a more aggressive manner, extending the shift points out and experiencing higher engine power. Eventually, the WOT shift tables can then be tuned.

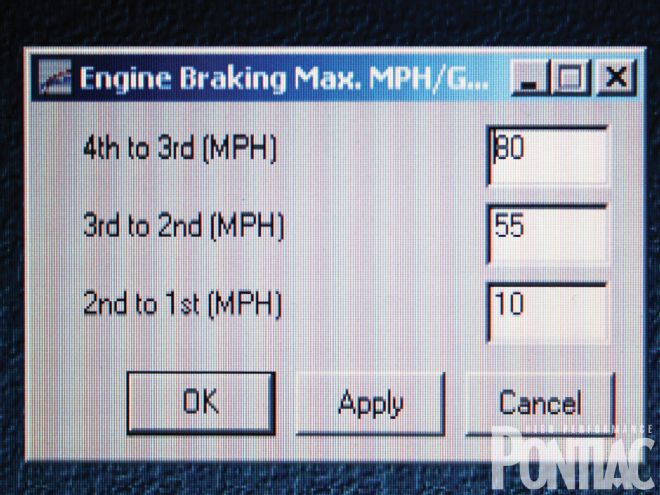

The maximum road speed that a manually forced down-shift (using the in-car shifter) can be evoked is tuneable.

The maximum road speed that a manually forced down-shift (using the in-car shifter) can be evoked is tuneable.

The part-throttle and light-load can be done very easily on the street, especially if you enlist someone to drive, while you make the changes. It is best to do the WOT tables either on a chassis dyno or at the dragstrip on a test-and-tune day. You don't want to break any laws or endanger anyone's life tuning your transmission.

When working with the calibration, don't forget that the way the transmission responds to downshifts is just as critical for proper driveability as the upshift logic. When cruising at a steady speed with the TCC engaged, any input into the throttle of more than a few degrees should first unlock the TCC; then, if aggressive enough, pull a downshift. Depending on the road speed and the amount of throttle input, the transmission may go down two gears instead of one.

For example, when you're out cruising about 35 mph on a level road, in most applications the transmission would be in Overdrive with the TCC engaged. Imagine a fellow in a Brand X car pulls alongside and wants to embarrass your Pontiac. When you whack the throttle to the floor, depending on the engine and rearend combination, the transmission may be required to provide a Four-to-One gear change momentarily, and then a rapid upshift to Second gear. The transmission's job is to fully exploit the power the engine makes in every rpm range-not work against it. If the transmission in your Pontiac was only to downshift to Third, or possibly Second gear, the other guy may very well get a jump on you if he's a good driver and his transmission is calibrated properly.

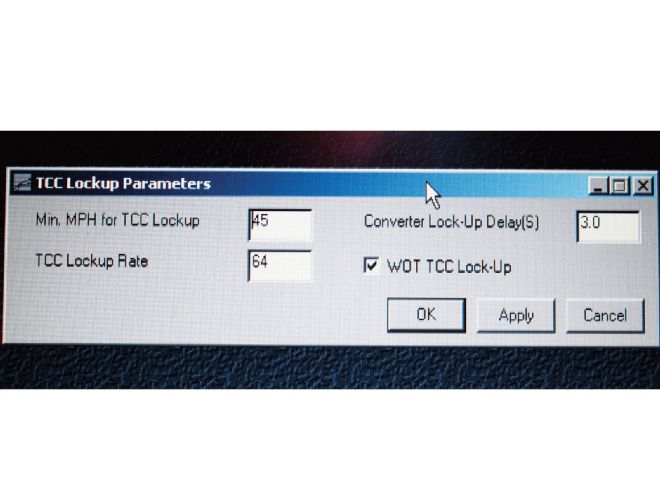

The TCC control strategy allows for improved performance and fuel economy with a number of different calibration tables.

The TCC control strategy allows for improved performance and fuel economy with a number of different calibration tables.

To create the perfect transmission strategy, the SuperMatic controller provides 15 different tables that you can alter. You were introduced to them in the third installment of this series, and we will go over them in a little more detail now.

Wide Open Throttle Minimum Shift Time: This needs to be in lock step with the transmission's mechanical ability to evoke a gear change. Ideal is without any electrical-induced delay over the inherent mechanical time. The time to create the shift should be precise with no lag.

WOT up-shift rpm and the kick-down mph are set by changing the number in the appropriate box.

WOT up-shift rpm and the kick-down mph are set by changing the number in the appropriate box.

Part Throttle Shift Time: The time required to complete the shift should be tuned to allow a seamless gear change with no confusion experienced by the transmission or engine.

Minimum TPS % for Idle: The TCU needs to assign a TPS voltage for closed throttle, so it can calculate the throttle opening as a transient value.

Maximum TPS % for WOT: Likewise the TCU needs to assign a maximum TPS value that coincides with full throttle.

Downshift Hysterisis MPH: This will control the road speed during coast-down. The transmission will go down a gear until it is back in First. It should be set for seamless coast-down, with no perceived flash in engine rpm or jolting of the Pontiac.

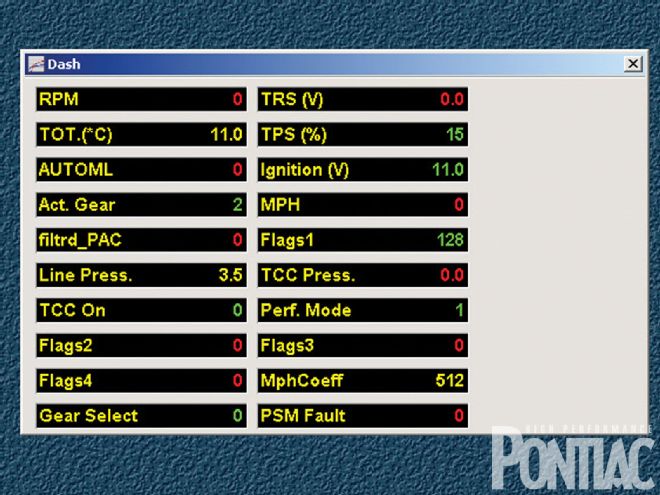

This is the same dashboard screen seen in image 4, but we now have evoked the Performance Mode signified by "Flags1" reading "128" and a "1" in the Performance Mode box.

This is the same dashboard screen seen in image 4, but we now have evoked the Performance Mode signified by "Flags1" reading "128" and a "1" in the Performance Mode box.

Reverse LP Kick %: This table works off the line-pressure calibration that is required when shifting into Reverse. The gear change should be smooth, with no pressure surge that will cause the Pontiac to bang into Reverse or jolt the torque converter.

Economy/Performance Kick %: This transmission offers both an economy and performance setting that alters the amount of line pressure in each mode. The performance calibration will increase the line pressure over the economy setting.

WOT Parameters: This is where the upshift rpm (which should be about 100- to 200-rpm below peak power) is tuned, along with the road speed to allow a forced WOT downshift.

TCC Lockup Parameters: The TCC should be evoked at a road speed and engine rpm that can accept it without intrusion to the vehicle or passengers/driver. The TCC should easily disengage, but not without any throttle movement. It should require a certain amount of opening. If the TCC is made too sensitive, it will constantly toggle on and off, and become an annoyance.

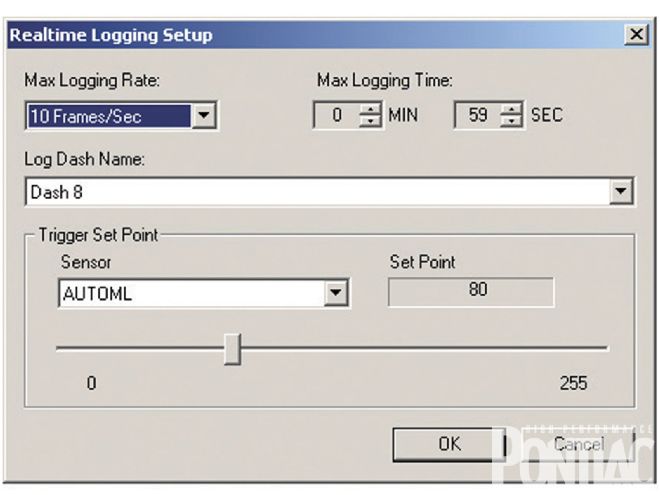

The TCU has the ability to offer user-selected data logging for tuning and diagnostic purposes. The parameters that you want to record need to be set.

The TCU has the ability to offer user-selected data logging for tuning and diagnostic purposes. The parameters that you want to record need to be set.

Minimum MPH for TCC Lockup: This table assigns a road speed and works in conjunction with the parameters table to fine-tune operation. Depending on your vehicle, a good rule is to have the TCC lockup at light load at around 35 mph. Remember, the mph table will only be allowed to lockup the converter after the parameter tables are satisfied. In calibration parlance, these are called "flags," so the values in the parameters table need to be met first, and then the road speed to engage the TCC.

TCC Lockup Rate: This manipulates the calibration so the converter can be engaged without excessive slippage, yet not be intrusive.

Converter Lockup Delay: This works along with the parameters setting, and allows slight throttle and load modulation without evoking a change in TCC status.

Engine Braking Parameters: This sets the maximum road speed at which the transmission can be forced into a lower gear with the shift lever.

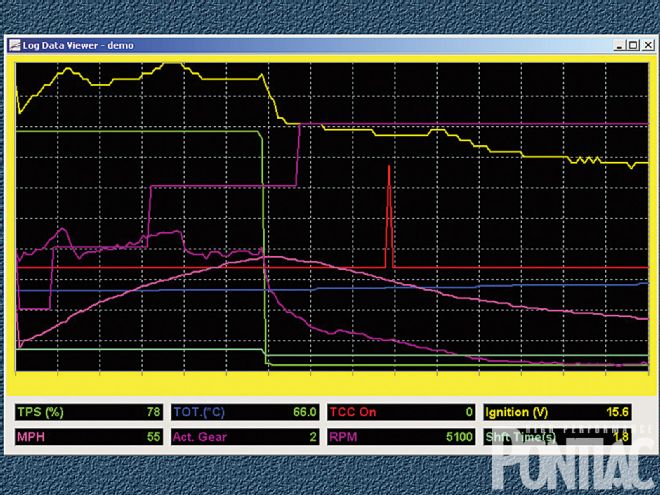

Once a data log is complete, the values can be seen in graph form with a different color for each parameter.

Once a data log is complete, the values can be seen in graph form with a different color for each parameter.

Slapstick Performance: This can be used to connect additional switches to control shift points, such as nitrous activation or to tune manual gear changes.

Force Motor Tables: The TCU allows line-pressure calibration for all gear changes, and those tables can be found under this heading. Again, at light load the line pressure should be sufficient to create a nice shift without clutch slippage, and increase as a function of engine torque output.

Conclusion

Though tuning the 4L85-E can be a very rewarding experience, it's best to first drive the Pontiac under varied operating conditions, noting any undesirable characteristics, if any, of the transmission's performance. Then you can use the tuning ability to make it into the automatic that you always wanted-one that enhances the excellence of a Pontiac engine.

Editor's note: Now that it's all finished, we can explain why Part IV of this story took so long to complete. When the GM Performance Parts TCU originally arrived, it was sans the CD or the USB-to-Serial computer cable to program it. (Don't worry: Yours will have them and our situation will be completely avoided.) We contacted GMPP and were told that we could simply download the program from the TCI website and we wouldn't need the CD.

In our application, the Performance/Economy mode, which raises the line pressure is evoked by a dashboard-mounted valet key switch.

In our application, the Performance/Economy mode, which raises the line pressure is evoked by a dashboard-mounted valet key switch.

Using the store-bought USB-to-Serial cable that Melvin Benzaquen, owner of Classic Restorations, previously employed to program a TCI TCU in a customer car, we tried to get started on the 4L85-E SuperMatic. It wouldn't work. The computer and the TCU would not speak to one another, and error codes ensued. On a long Saturday, we tried two cables and three different laptops-two PCs and a Mac-but nothing helped.

GMPP recommended we call TCI. Russell Culver, a tech at TCI, was very helpful. He said it was most likely the cable, but he told us to send him the TCU just to be sure. We soon learned that the TCU would only work with the TCI and/or GMPP-provided cable, despite the fact that these are not proprietary cables. Russell sent it back with the cable he used, and we were golden. See? Magazines run into the same issues that you do.

The moral of the story? Only use the cable that is supposed to be supplied. Ed.