Thanks to performance driveshaft companies like Inland Empire Driveline Service, you don't have to hope that your U-joints and pinion yoke can stand up to your high-horsepower abuse. To handle whatever you are driving, there are four material options for the tube itself, plus a couple of choices for the pinion and transmission yoke. So crack a cold one and take a look at some simple parts to keep things spinning where the sun don't shine.

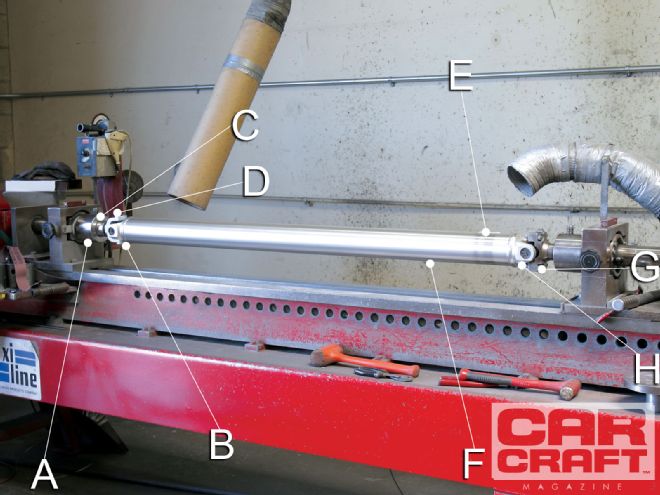

A. On the left is the 1310 transmission slip-yoke usually found on OE applications. The yoke on the right is the larger 1350 yoke. Both are available in 27-32 spline count. Start thinking about the larger yoke when approaching 500 engine horsepower, but there are cases where you can get away with more. Be sure to know everything about your power and vehicle weight when you call to order the parts.

A. On the left is the 1310 transmission slip-yoke usually found on OE applications. The yoke on the right is the larger 1350 yoke. Both are available in 27-32 spline count. Start thinking about the larger yoke when approaching 500 engine horsepower, but there are cases where you can get away with more. Be sure to know everything about your power and vehicle weight when you call to order the parts.

B. This is called the weld yoke. It slides inside the tube and is TIG-welded in place. Note the 1350 U-joint.

B. This is called the weld yoke. It slides inside the tube and is TIG-welded in place. Note the 1350 U-joint.

C. If you really want to throw down, you can also step up to the 4140 chrome-moly yoke with ARP bolts. Note that it uses torque caps instead of the standard press-in design.

C. If you really want to throw down, you can also step up to the 4140 chrome-moly yoke with ARP bolts. Note that it uses torque caps instead of the standard press-in design.

D. The recommended play for the slip-yoke is 3/4 inch on the inside. That will always ensure the correct play between the seal on the transmission and the face of the yoke. When measuring for a driveshaft, the length of the transmission output shaft protrusion is required in addition to the distance between the tip of the output shaft and the centerline of the U-joint at the pinion yoke (the flat surface where the U-bolt hole is drilled).

D. The recommended play for the slip-yoke is 3/4 inch on the inside. That will always ensure the correct play between the seal on the transmission and the face of the yoke. When measuring for a driveshaft, the length of the transmission output shaft protrusion is required in addition to the distance between the tip of the output shaft and the centerline of the U-joint at the pinion yoke (the flat surface where the U-bolt hole is drilled).

E. Most driveshafts are balanced to 3,000-3,500 rpm from the factory and spinning them faster than that causes dangerous vibrations and parasitic power loses. Gear ratio changes and high-speed racing require the shaft to be balanced at 5,000 and up to 7,500 rpm.

E. Most driveshafts are balanced to 3,000-3,500 rpm from the factory and spinning them faster than that causes dangerous vibrations and parasitic power loses. Gear ratio changes and high-speed racing require the shaft to be balanced at 5,000 and up to 7,500 rpm.

F. Rocky Maldonado is holding a 6061 T6 aluminum driveshaft tube. Stock vehicles used to have mild-steel tubes standard but now it’s not uncommon to see a factory aluminum driveshaft in a performance car. The next step up is chrome-moly then carbon fiber for all out performance and price. Likely, aluminum will fit your performance needs.

F. Rocky Maldonado is holding a 6061 T6 aluminum driveshaft tube. Stock vehicles used to have mild-steel tubes standard but now it’s not uncommon to see a factory aluminum driveshaft in a performance car. The next step up is chrome-moly then carbon fiber for all out performance and price. Likely, aluminum will fit your performance needs.

G. Aluminum reduces rotational mass but you still have to be aware of the critical speed where any shaft begins to vibrate and bend. As the shaft gets longer, it needs to get larger in diameter to raise the critical speed to a safe level.

G. Aluminum reduces rotational mass but you still have to be aware of the critical speed where any shaft begins to vibrate and bend. As the shaft gets longer, it needs to get larger in diameter to raise the critical speed to a safe level.

H. The pinion yoke on the left is for the smaller 1310. A quick way to tell these apart is measure the diameter of the u-joint at its cap. The 1310 is 1 3/16-inch instead of 1 3/8-inch

H. The pinion yoke on the left is for the smaller 1310. A quick way to tell these apart is measure the diameter of the u-joint at its cap. The 1310 is 1 3/16-inch instead of 1 3/8-inch

I. On the left is the 1310 u-joint and on the right is the 1350. Note that neither have a grease Zerk fitting that reduces their strength. Solid u-joints are lubed-for-life.

I. On the left is the 1310 u-joint and on the right is the 1350. Note that neither have a grease Zerk fitting that reduces their strength. Solid u-joints are lubed-for-life.