| Salt flat Monster - Question It

| Salt flat Monster - Question It

Eric would like to wish everyone belated happy holidays with his friendly smile and cheerful demeanor. Technically, this issue hits newsstands in February, but in the magazine world . . . we’re still stuck in December—the month to be joyous and festive. Eric forewarns those in the gift-giving mood to resist buying knock-off parts for friends and family. “If you’re going to buy cheap Chinese knock-off crap, buy an egg timer or chopsticks. Not engine components. Happy holidays!”

Got a tech question?

Send it to questionit@importtuner.com

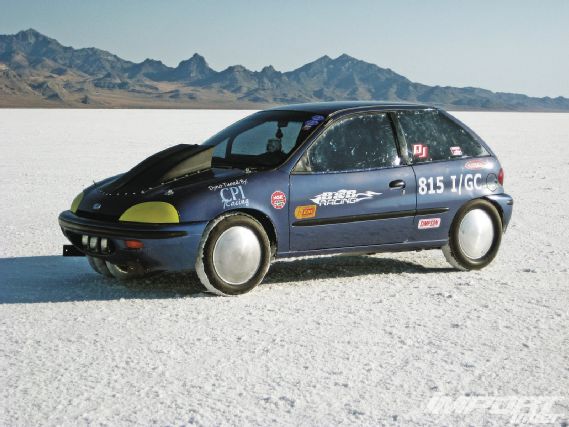

Salt Flat Monster

I own a ’96 Geo Metro hatchback that I run on the Bonneville Salt Flats. A naturally aspirated Arctic Cat snowmobile engine powers it, and it is still using the stock Metro transaxle. To date, the car has campaigned a best top speed of 142 mph. I have two questions.

|

Salt flat Monster - Question It

|

Salt flat Monster - Question It

1. Transaxle/gears:

Do you know anyone who makes gears for this transaxle? Going from Third to Fourth gear is quite a stretch, and the two-stroke has a hard time recovering. If a gear isn’t available, is there a different transaxle? I have a universal adapter plate that the transaxle can bolt up to, as long as the transaxle is pretty much the same distance in length. What transaxle would be good? Do any offer different gears that can be used, or are there other transaxles that are better to modify?

2. Body kit/wind splitter/front air dam/spoiler:

Very little, if any, aftermarket parts are available for my Metro in this area. However, that being said, I was looking at an advertiser in your publication, and they offer universal body kits, front air dams, and more. Can you advise me or point me in the direction that would best suit my car’s needs? I happened to come across your magazine’s November issue, and the car on the cover has bumper air splitters that look rather interesting, do these work?

-Clay,

via importtuner.com

That is a cool-looking little Geo. You’ve probably gone above and beyond anybody else who has ever built a Geo for motorsports use. That said, there is probably going to be very little knowledge in regards to the Geo platform and its parts. I doubt that any company ever designed replacement gears for the factory Geo transaxle. It might be worth studying the ratios of other years or models of Geos to see if there’s a suitable ratio, but the ability to use the new ratio inside of your current Geo transaxle will be something you’ll have to discover on your own. You’re probably going to be better off finding a different transaxle from some other three or four-cylinder subcompact car with better gear spacing. I would imagine finding a transaxle from something with a smaller, more responsive engine such as a Honda City, Honda Fit/Jazz, Suzuki Cappuccino, or Suzuki Swift might be a good starting point. You should be able to find their factory gear ratios on the web for comparison purposes.

As for aero mods, you’ll probably be forced to modify universal parts and/or fabricate parts from scratch. The subject of aero can literally be books in itself so I won’t be able to cover the entire subject in this response. I do recommend getting yourself a copy of New Directions in Race Car Aerodynamics: Designing for Speed (Engineering and Performance) by Joseph Katz. I have a copy of the first edition that I refer to regularly, but I have found this is an excellent book to suggest to those who genuinely want to learn about automotive aerodynamics.

Utter Confusion

My chassis is a Civic EG6 with (OBD-I), my engine is an F23 SOHC VTEC with OBD-II, and my ECU is a P28 with an F23 base map. I’m currently using an OBD-I B-series engine harness. Can I use OBD-I B-series injectors in the F23 since I am using an OBD-I ECU and harness, or do I have to use F23 injectors and a damn resistor box? I believe the F23 injectors are 240cc saturated, as are the same as the B-series injectors, so it should be fine?

-Josh,

via importtuner.com

You can use whatever injector or injector/resistor box combination you want as long as the ECU will be remapped accordingly. But if you are truly running an F23 base map, then I’ll assume you’ll want to run the F23 injectors since that is what the ECU is mapped for. Injector resistor boxes are only used with peak and hold injectors in factory applications. The resistor box adds resistance to the circuit and lowers the overall current so it is easier for the lower-grade transistors of a mass-produced ECU to drive peak and hold injectors. I think only “OBD-0” Hondas used peak and hold injectors so you’ll be OK switching between the F23 and B-series injectors.

Quality Hose Clamps

Over the past few magazines I’ve noticed that a lot of these high-horsepower machines use regular worm-style clamps on fuel injection setups. Is there a reason why they can use these clamps instead of T-bolt clamps? Every turbo car I have owned if I up the boost, encounter the dreaded “pop” while using factory fasteners. Does this have to do with the type of intercooler piping, diameter, routing, BOV, or are these just mock-ups to get the cars up and running for the photo shoots? Or is there some type of big secret the big shots know that we don’t?

|

Salt flat Monster - Question It

|

Salt flat Monster - Question It

-Clint Cooper,

via importtuner.com

I have never used T-bolt clamps on a build unless a customer specifically requested them. If the intercooler tubes are properly designed, bracketed when necessary, and the correct choice of transition hose is used, there should never be a need for anything other than a traditional worm drive clamp unless a gazillion pounds of boost is going to be run (e.g. tractor pull or drag car). I’m not going to be able to explain when and where to add a tube bracket or specifically what type of transition hose to use in every situation here in Question IT, but I can tell you that experienced fabricators familiar with intercoolers and companies who have a lot of experience producing intercooler systems (e.g. HKS and Greddy) will generally build the most reliable intercooler systems around. You pay for what you get in this instance. It’s easy for any idiot to weld some tubes together, pick some random hoses, and then use T-bolt clamps as a Band-Aid for improper tube design and poor hose choice. Sure, your hoses may not “pop” with a poorly designed intercooler system and a bunch of T-bolt clamps, but you’ll have rattling tubes, noises on application of torque, and a bunch of ugly T-bolt clamps underhood with 2 inches of stud sticking out waiting to gouge the skin on your forearm when you’re trying to reach for something.

Other than being an eyesore, T-bolt clamps are fine when used correctly. But here are some things to look out for when using them:

1. Do not over torque them. When using with aluminum tube, T-bolt clamps can deform the tube quite easily. Always follow the manufacturer’s recommended torque setting. I’ve seen many idiots crank way too hard on T-bolt nuts.

2. When using T-bolt clamps, I recommend using four-ply silicone, thick rubber, or marine exhaust transition hoses. T-bolt clamps sometimes leak when using thinner two- or three-ply silicone hoses because the force is not applied 100 percent circumferential (underneath the bolt typically).

3. Use T-bolt clamps made in the USA. A whole slew of cheap, made-in-China “stainless steel” T-bolt clamps are flooding the market that rust, strip, and have spot welds that will fail.

Future Engineer

I own a ’98 Mitsubishi Galant with a 4G64 engine and mild modifications. It has over 150K miles and has seen its share of dings and worn-out components caused by Missouri’s storms. I recently got into an argument with a friend over whether I should sell the car and start over or keep the car. My original plan was to acquire a 4363T head and convert my 2.4L engine into a turbocharged Frankenstein-style motor. I was wondering if you thought the Galant could be used as a decent platform or if I should give into peer pressure and scrap the project? As a mechanical engineer major on Mizzou’s FSAE Formula Car Team I have experience fabricating race car components, but it is an expensive and time-consuming process to do so. If I were to keep the platform, do you know of anywhere I might be able to find aftermarket support?

-Derrik Roll

Jefferson City, MO

I don’t think you’ll find too much aftermarket support for the ’98 Galant outside of lower springs, shocks, some brake upgrades, and some basic intake systems. That’s something you generally have to prepare yourself for when trying to tackle the build of a rare vehicle. The good news is that a 4G63 will bolt right in, and it is likely that the turbo and intake manifolds of an Eclipse will also fit with some minor tweaks here and there. Start searching for information on Galant forums for some help from the fellow Galant community, but I think you’ll find that you’ll be one of the few doing what you want to do. The good news is that the open source ECU flashing software, ECU flash, supports your car, which should make life a bit easier when you finally make the transition to turbo power. Good luck and let us know how it goes.

Naturally Aspirated Power

I’ve gotten a headache from reading forum posts so I decided to get your professional opinion. I’m sure you get this all the time, so I apologize in advance, but your insight and direction would be appreciated. I have a ’04 Subaru Impreza 2.5RS with 121K miles on it. It was my daily driver for six years and now gets used during the winter. I don’t abuse my cars, so I figure in another four to five years my Impreza will have a well-earned 200,000 on the powertrain. I’ll be replacing it with a newer Impreza for daily use. I was thinking of making a clean street-driven vehicle to autocross, take to track days, and just whip around on the highway, done on a reasonable budget. I have the suspension and wheels sorted out, keeping it simple. Then, there is the engine—that’s where I’m uncertain and unclear. I’m staying naturally aspirated by choice because I just want a fun car that won’t be complicated to repair when something malfunctions. Aside from an aftermarket intake, headers, and exhaust, I’ll have a lot of miles on the engine. I want to maximize the performance of a simple engine. I thought just rebuilding the block with stock components and focus on porting and polishing the heads for better flow and breathing would improve the power output slightly. Am I heading in the right direction?

|

Salt flat Monster - Question It

|

Salt flat Monster - Question It

-Kwame,

via importtuner.com

If you want to keep your car normally aspirated, then yes, you’re heading in the right direction. All you can really do is increase airflow through the engine to increase power output, but in a street car, the trick is to do this without hurting torque and engine response. Be sure to avoid headers, exhaust systems, and camshafts designed for race applications; these kinds of parts often reduce a car’s overall performance on the street. A high-flow intake system, a set of exhaust headers, a good street exhaust system, and even a high-flow cat will also help enhance the engine’s output. For a street car, engine modifications should be limited to a very simple port and blend job (i.e. more of a clean up than anything), a good multi-angle valve job, a mild set of cams, and possibly increasing the compression ratio by using either pistons from another year or model, or forged pistons. If you’re planning on using super unleaded fuel, then you should be able to increase the compression ratio to something more along the lines of 11.0:1. Of course, all of this needs to be orchestrated by a good ECU remapping session to bring out the benefits of all the new work and to ensure engine safety. With these kinds of mods, it would be realistic to add another 40-50 hp to the engine’s output. The thing to keep in mind is to remember that the next guy who just bolted on a 5 psi turbo system on his 2.5RS is probably still going to smoke you at a street light confrontation. Otherwise, good luck with the build and let us know how it goes.

Free Clinic

I own a ’91 240SX with the stock KA24DE engine with some light mods consisting of an intake, exhaust, and LSD. I recently experienced a problem when accelerating as I reach high rpm. The car makes uncharacteristic clicking sounds and feels extra sluggish. Some of my friends told me it might be my valves or rocker arms or something else. I just want to know what you think the problem is, how much would it take to fix, and how much would it be to replace with reliable aftermarket parts.

-Joshua Cruz,

via importtuner.com

It’s nearly impossible to diagnose a “click” or a “tap” via email so I recommend taking the car to a reputable mechanic. When you feel sick, do you call your doctor and say, “My side hurts. What’s wrong with me?” If you tried that, your doctor would ask you to come in for an examination, right? It’s no different with a car.

I can tell you that it won’t be a rocker arm issue since a KA24DE doesn’t have rocker arms. It uses direct acting tappet buckets. Otherwise, it could be a spun rod bearing, a bent valve, or any other number of things.