Send your letters to planetdave@me.com

When I built my first serious race engine, a Honda B18C with Toda high-compression pistons and camshafts, a knife-edged crankshaft, a Supertech valvetrain, and a ported cylinder head, I threw a low-temperature thermostat in while I was at it. I really didn’t give it much thought, since it was a pretty standard upgrade in the Honda racing community and it was inexpensive and easy to do. The basic theory seemed sound enough: the t-stat opening at a lower temperature than stock so coolant can flow to the radiator sooner in an effort keep temps down.

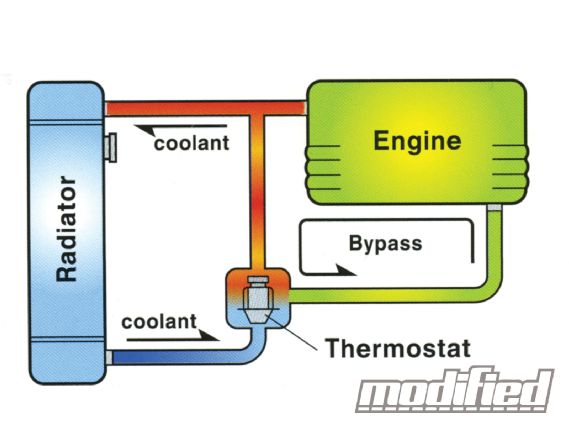

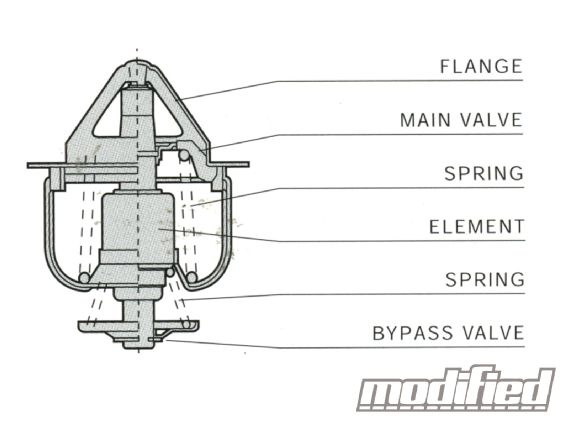

I’ve since learned there’s a lot more to thermostats than just the temperature at which they open, including how these seemingly simple little devices do their job. Positioned between the engine and the radiator, the thermostat is a temperature-sensing valve that controls the flow of coolant between the two. At its heart is what’s called the Element, which is filled with paraffin wax. As the engine heats up, the wax gets hotter and expands and in the process pushes the main valve open. The amount the valve opens, and thus the relationship between coolant temperature and coolant flow to the radiator, is determined by a combination of the force of the paraffin wax expanding and the stiffness (or spring rate) of the spring used to return the valve to the closed position. There’s also a bypass valve that allows water to flow through the thermostat (but not to the radiator) when the main valve is closed, so the coolant in the engine warms up uniformly and to ensure the Element is exposed to sufficient coolant flow to react as temperature rises.

As most of you already understand, especially if you’ve ever had a thermostat stick open, the most obvious roll of the thermostat is to restrict coolant flow to the radiator so the engine warms up faster. This is an especially important job, since vital engine parts such as bearings and rings suffer the most wear and tear when operating at colder temperatures. A warm engine (meaning at its optimum operating temperature) is a happy engine, with very little friction-related wear and tear occurring.

Limiting wear isn’t necessarily a big concern with a race engine, though, since the expectation is for a short service life anyway. But the thermostat’s flow control is still very important, since running without the restriction provided by a t-stat often means the coolant passes through the radiator too quickly and the engine overheats as a result. In rare cases, race teams run without a thermostat, but in general, the coolant system needs some restriction to allow the radiator to do its job, not to mention the slower warm-up and increased engine wear that comes with the decision to run without one.

| The thermostat plays a vital role in engine performance by controlling coolant flow between the engine and radiator so engine temperature is kept in the optimum range.

| The thermostat plays a vital role in engine performance by controlling coolant flow between the engine and radiator so engine temperature is kept in the optimum range.

So the thermostat, be it a standard-temperature OE model or a low-temperature design, not only helps the engine warm up quickly and sets the point at which coolant is allowed to flow more freely to the radiator, but it also helps control coolant flow so the radiator can function properly and the engine is kept at its optimal operating temperature. But are all thermostats pretty much created equally, or are there meaningful design differences between the no-name replacement t-stats you can buy at discount auto parts stores and the high-performance aftermarket versions produced by industry leaders like Nippon Thermostat Co. Ltd (NTCL)?

NTCL has been in the thermostat business since 1954 and its products are currently used in more than 50 percent of the cars produced in Japan. Plus they’re widely used in motorsports, including in two of the most grueling tests a combustion engine can endure: Le Mans and WRC. If you think about the consequences of a failed thermostat and the rapid engine overheating that follows, the importance of thermostat durability is obvious. So as you’d expect given thermostats’ widespread use in racing environments, NTCL does extensive durability testing on its low-temperature thermostats, including repeated heating and cooling cycles, vibration testing, engine bench testing, and, of course, real-world testing in road cars and race cars.

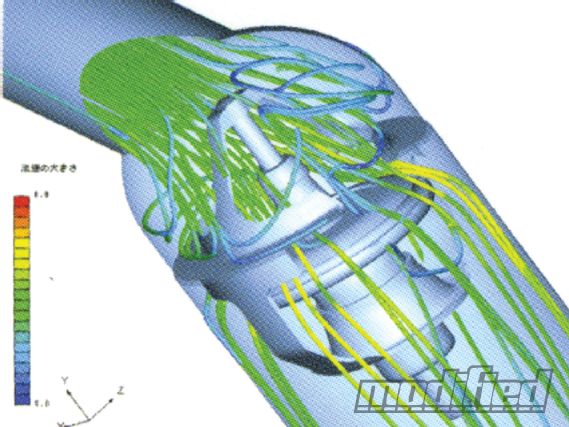

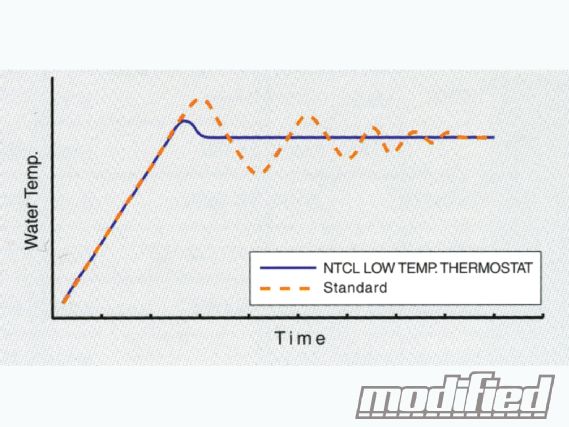

Where the performance of a thermostat is less obvious is with respect to its flow characteristics and how this impacts overall engine cooling. Hunting, meaning dramatic changes in coolant temperature, is a common problem with lower-quality thermostats because they allow too much flow when wide open. In a worst-case scenario, hunting can result in a cracked cylinder head from being exposed to such dramatic changes in temperatures, and at the very least it causes a significant reduction in the efficiency of the cooling system.

NTCL’s low-temperature thermostats are engineered to prevent hunting, thanks to the company’s use of three-dimensional computational fluid dynamics during the design, development, and analysis stages. These high-performance t-stats are also designed using a patented main valve that opens in a more controlled fashion, preventing coolant from suddenly rushing to the radiator and causing the rapid change in coolant temperature associated with hunting.

| At the heart of the thermostat is the Element, which is filled with paraffin wax that expands with heat and pushes the main valve open in the process.

| At the heart of the thermostat is the Element, which is filled with paraffin wax that expands with heat and pushes the main valve open in the process.

As far as the advantages of opening the thermostat’s valve at a lower temperature goes, there are proven benefits in a high-performance or race environment.

The key to low-temp thermostat success is that coolant is allowed to flow more freely during low load sections of the racetrack, ensuring that the radiator is able to keep the engine within the optimal temperature range in the high-load sections of the track. So if you’re maxing out your cooling system at the racetrack and experiencing some overheating issues, for example, a low-temp thermostat will often solve this problem by letting the radiator work more at part-throttle lower engine loads and in the process delay or completely eliminate any overheating during wide-open throttle high-engine loads.

Ultimately the maximum heat control capacity of any cooling system is determined by the size and efficiency of its radiator(s) or heat exchanger(s), but the thermostat does play a surprisingly important role given what an outwardly simple device it would appear to be. But as Nippon Thermostat Co. Ltd has proven with superior durability and flow control, a high-quality thermostat can also prevent unwanted temperature hunting, and a low-temperature thermostat can, in fact, prevent overheating by allowing the radiator to do more cooling sooner and in the process prevent the system from getting overloaded.

The key to low-temp thermostat success is that coolant is allowed to flow more freely during low load sections of the racetrack, ensuring that the radiator is able to keep the engine within the optimal temperature range in the high-load sections of the track.

Ultimately the maximum heat control capacity of any cooling system is determined by the size and efficiency of its radiators(s) or heat exchangers(s), but the thermostat does play a suprisingly important role given what an outwardly simple device it would appear to be. But as Nippon Thermostat Co, Ltd has proven with superior durability and flow control, a high-quality thermostat can also prevent unwanted temperature hunting, and a low-temperature thermostat can, in fact, prevent overheating by allowing the radiator to do more cooling sooner and in the process prevent the system from getting overloaded.

| Low Temp Thermostats Flow

| Low Temp Thermostats Flow

| Hunting, in which coolant temperature swings dramatically from hot to cold, is a dangerous condition Nippon Thermostat Co. Ltd has eliminated thanks to CFD-based design and extensive laboratory and real-world testing during the development of its industry-leading thermostats.

| Hunting, in which coolant temperature swings dramatically from hot to cold, is a dangerous condition Nippon Thermostat Co. Ltd has eliminated thanks to CFD-based design and extensive laboratory and real-world testing during the development of its industry-leading thermostats.