AEM's Infinity stand-alone EMS is next generation in every sense, from its rugged construction that allows it to be mounted in the engine bayto its Internal Simulator that lets you test tuning changes without having to run the engine.

AEM's Infinity stand-alone EMS is next generation in every sense, from its rugged construction that allows it to be mounted in the engine bayto its Internal Simulator that lets you test tuning changes without having to run the engine.

If you’ve been modifying Japanese imports for a more than a few years, chances are you’ve installed an AEM cold-air intake on a car or two. These cleverly engineered long-tube intake systems have stood the test of time, proving their effectiveness thousands of times on the dyno and turning more than a few heads thanks to their unique induction noise. But as the name suggests (AEM stands for Advanced Engine Management), this Hawthorne, California-based manufacturer has a lot more going on than just “filters on a stick.”

AEM actually started out as a tuning facility, so engine management has always been in its blood. Back in the day, AEM was the R&D department for Redline/Weber, becoming a stand-alone facility in 1987. A decade later it became a full-time manufacturer, re-entering the electronics/engine management world in 2003 with its now-famous Series 1 EMS. The Series 1 EMS was so impressive that it won the Primedia Technology Award in 2004 as the first EMS to plug into a factory harness. That year also marked the introduction of its first-generation wide-band controllers, and in 2005, AEM introduced the first wide-band controller gauge on the market.

Clearly the company has been a leader and an innovator in the performance electronics industry, and better still is the fact that it brought these products to the masses thanks to pricing that didn’t require organ donation. That’s really the beauty of AEM’s approach to performance electronics and engine management: Regular guys like you and me who before could only dream of owning the electronic unobtanium we’d see on professional race cars suddenly found it within reach. And now, with AEM’s new Infinity EMS, the bar has been raised even higher in the world of affordable engine management thanks to a whole host of new and innovative features and options that not only make ECU tuning easier and more accurate but also make it safer and more reliable.

To give you a quick idea of how advanced the Infinity is compared with the previous-generation unit (Series 2 EMS), check out the chart for a side-by-side comparo. It’s pretty telling stuff, with highlights than include a 32-bit 200-mhz CPU core capable of executing 400 million instructors per second, making it 20 times faster than the previous-gen ECM. It also has far more sophisticated data logging, traction control, and knock sensing capabilities that we’ll get into later, along with a super robust case that makes it suitable for engine bay mounting.

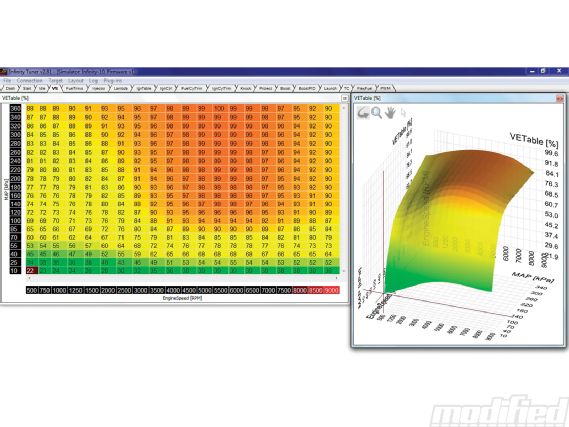

| The game changer with the Infinity EMS is the way it uses airflow model- or volumetric efficiency- (VE) based calculations when developing its maps, rather than the old injector pulse-width approach.

| The game changer with the Infinity EMS is the way it uses airflow model- or volumetric efficiency- (VE) based calculations when developing its maps, rather than the old injector pulse-width approach.

But what really sets the Infinity EMS apart is, according to AEM Marketing and PR Director Lawson Mollica, its ability to do airflow model-based calculations. “The real benefit of an airflow model, and therefore VE- [volumetric efficiency] based tuning, is that the numbers make inherent sense to the tuner without any additional knowledge required. In older injector pulse-width-style systems, the main tuning tables work in units of time, or milliseconds of injector-on time. These numbers are meaningless on their own, and without injector flow information, the number of injectors, the size of the engine, and so on, the tuner can’t say what the table actually means. Is 6 ms of fuel rich? Is it lean? You can’t know without more information. With VE model-based tuning, the general airflow characteristics of the engine are tuned, not the specifics; you leave that up to the model. Now you simply have to tell the system how good the engine breathes at different operating points. Even if you are off in your initial estimates, you are still going to be pretty close, and it’s easy to make the initial estimates because the numbers make sense. You let the model take care of the effects of temps, pressures, gas constants, engine displacement, and other factors. What this means, essentially, is that you can be way off your optimum VE number and the car will still run because all these other variables are in play.”

This change to airflow model-based calculations based on the engine’s volumetric efficiency not only makes tuning far more intuitive, but when combined with some of the Infinity’s other features, it also makes it a far safer stand-alone system to tune with. One such feature is the Internal Simulator, which allows the user to simulate input channels to the Infinity EMS. As Lawson explained, “If you know a given engine combination should make a certain amount of horsepower and you have a certain size injector, with experience, you will know at WOT what your injector duty cycle value will be. You can plug all that data into your VE table and then the simulator will show you what the ECU will do under those circumstances, without actually having to run the engine, which means you can test changes to the VE table without putting the engine at risk.”

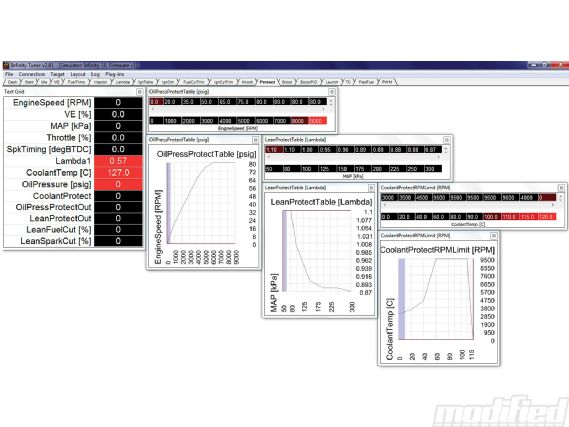

| Another major innovation with the Infinity is how it uses a wide array of data sources as part of its engine protection system.

| Another major innovation with the Infinity is how it uses a wide array of data sources as part of its engine protection system.

As part of the Infinity’s integrated protection strategy, this groundbreaking EMS also looks very closely at other values provided by the knock sensor, wide-band sensors, temperature and pressures sensors, and even engine speed (to protect against an over-rev). There are a number of different protection modes you can choose from, and each one allows you to define an engine speed if a particular condition occurs. As Lawson pointed out, “The system prioritizes by selecting the lowest value and applying the defined strategy for limiting the speed, while at the same time it can trigger an output to activate a warning light. It doesn’t necessarily prioritize one condition over another. Rather, it responds based on the values it sees, which are user defined.” So if you want your engine to respond by going to a safe engine speed as soon as it sees air/fuel above a ratio of 13.5:1, it’ll do that. Or if you want it to cut revs as soon as the knock sensor shows the tiniest sign of detonation, it can do that, too.

This is some high-end engine protection and mapping technology, something you’d normally only have access to with big-dollar units from companies like Motec that require a totally custom wiring setup (which adds even more to the cost). But given AEM’s commitment to plug-and-play solutions, you can expect to see the company aggressively expand the list of vehicles it will be offering a PnP version of the Infinity for. Right now that list only includes 2JZ-powered vehicles, but the next round of PnP apps will include the Nissan 350Z and BMW M3. In addition to PnP development, AEM is also working on a variety of “supported” applications for Infinity, which will enable adaptation to a variety of platforms with use of a universal wire harness and wiring schematic. Existing supported applications include Ford modular engines, Dodge Hemi engines, GM LS engines, Mitsubishi 4G63 and the 4B11 engines, and, of course, popular Honda engines. And in the meantime, if you’ve gotta have a PnP solution right now, then there’s the Series 2 EMS for that.

Even if you are off in your initial estimates, you are still going to be pretty close, and it’s easy to make the initial estimates because the numbers make sense.

It’s interesting to see that AEM will be providing the Infinity EMS in a variety of configurations based on the number of cylinders it supports, with the Infinity-6 supporting up to six cylinders, the Infinity-8 handling up to 8 cylinders, and so on. According to Lawson, “The systems will be priced accordingly. Essentially, the Infinity allows us to develop applications that were challenging with our previous software architecture, so it’s safe to say you will see applications for exotics in the future in addition to many more domestic V8 applications. We also anticipate seeing Infinity-8s and -10s on four-cylinder race cars with staged injection, etc. These systems are designed for high-performance racing applications including pro racing.”

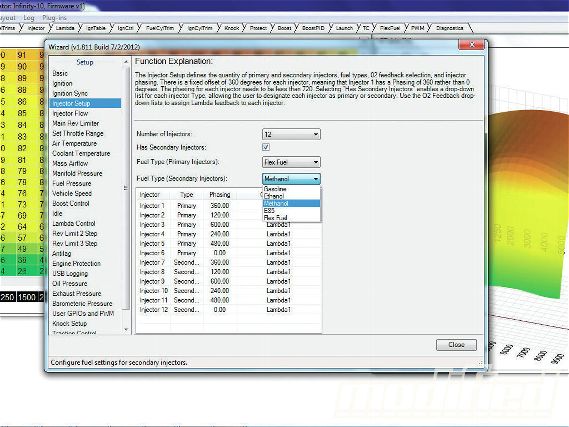

| AEM has clearly been paying close attention to fuel trends, because it has equipped the Infinity with the ability to compensate for a wide variety of fuel types, including E85 and methanol.

| AEM has clearly been paying close attention to fuel trends, because it has equipped the Infinity with the ability to compensate for a wide variety of fuel types, including E85 and methanol.

With pricing expected to be in the $2K range to start, the Infinity isn’t going to be the right solution for someone who really only wants or needs a basic tune or reflash to optimize engine performance after having bolted up a few basic upgrades. This unit is clearly more in line with the needs of race teams or highly modified cars that need advanced engine management and engine protection for their fully built powertrains. It’s also going to be appealing to guys running multiple fuels, since the Infinity has flex fuel compensation, plus it’s compatible with drive-by-wire systems and has real-time diagnostics for those emergency repairs in the paddock when the clock is ticking.

The rate of advancement in the engine management industry is pretty mind-blowing. It wasn’t that long ago we were all tuning with low-resolution piggyback fuel controllers, adding big chunks of fuel across relatively large rpm ranges. So looking at AEM’s Infinity EMS feels a bit like looking into the future for me, and I’m personally very excited to see firsthand what the tuning experience is like with one of these amazingly little black boxes. A plug-and-play app for rotary engines, AEM? Come on, you know you want to!

Send your feedback to PlanetDave@me.com

|

To Infinity and Beyond - Tech Talk

|

To Infinity and Beyond - Tech Talk