We've all heard the term "There's no replacement for displacement" more often than we care to recall, and when comparing big and small engines with similar induction methods, the cliché typically holds true. There are exceptions to every rule, however, so when the guys at Hughes Engines and the Supercharger Store said they wanted to build a Chrysler 318 that would meet or exceed the horsepower and torque numbers of a normally aspirated stroker big-block, and further, the engine would idle nicely, produce enough manifold vacuum for power brakes, and run on pump gas, we had to follow along to see how close they could come to achieving these goals.

Is there really a replacement for displacement? This month we'll find out as we attempt to achieve big-block numbers from a mild 318.

Is there really a replacement for displacement? This month we'll find out as we attempt to achieve big-block numbers from a mild 318.

Of course we all know that building a normally-aspirated 318 that would out-power a stroker big-block would be an extremely difficult feat, resulting in an engine that would hardly be streetable and likely wouldn't idle well or run on pump fuel at all. So, to see the expected results, this build would require the benefit of forced induction. And while some of you envision cutting a hole in the hood for an unsightly supercharger, the truth is there are many options when it comes to forcing air into your Mopar engine, one of the least intrusive being a centrifugal supercharger like those manufactured by ProCharger.

Since centrifugal superchargers are small in size, can be located under the hood, and spun in conjunction with other accessories like the alternator and water pump, and are easy to intercool, a ProCharger D1SC supercharger with a water injection system from the Supercharger Store was picked for this project. The idea was to build a somewhat mild 318, and through a moderate and reliable level of boost, increase the engine's output to an incredible 650 horsepower and 600 lb/ft of torque, while not making a huge sacrifice in drivability or economy. To get started, Hughes Engines offered to build a 318 for the project that isn't too far from the typical small-blocks our readers have likely built for their cars.

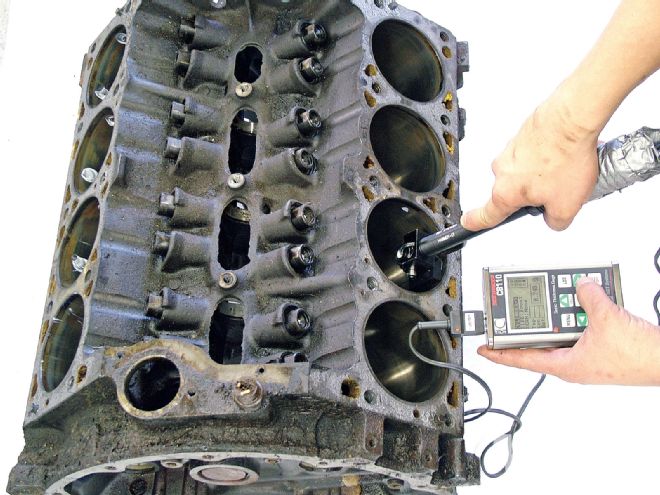

Finding buildable Mopar blocks can be difficult, but since they didn't make any heavy-duty factory 318 blocks, extra care must be taken for a performance build. Hughes Engines magnafluxed and pressure tested this block, and then sonic checked all the cylinders in a minimum of twelve different places before deeming it buildable.

Finding buildable Mopar blocks can be difficult, but since they didn't make any heavy-duty factory 318 blocks, extra care must be taken for a performance build. Hughes Engines magnafluxed and pressure tested this block, and then sonic checked all the cylinders in a minimum of twelve different places before deeming it buildable.

After some searching, Dave Hughes found a 318 that would pass his stringent requirements for cylinder wall thickness, magnetic particle testing, and would handle a cooling system pressure test to 30 psi. Once these tests were finished, the block was treated to a complete cleaning, boring, squaring, and honing with torque plates, and the decks surfaced to be completely flat. An Eagle forged-crankshaft was utilized with Eagle H-beam connecting rods, and Diamond forged pistons with a custom 21cc dish and coated skirts were matched with Total Seal metric rings for an 8.5:1 compression ratio, and the entire rotating assembly was balanced. Since the Chrysler small-block has numerous oil system issues in stock form, Hughes also blueprinted the oil system for optimum performance, installed a 10-inch-deep Moroso pan to keep oil away from the rotating assembly, and used one of their main girdles for additional support and reduced crankcase windage.

Racing Head Service (RHS) provided a pair of their new "X" castings for the engine, which are a big improvement over stock cylinder heads. The RHS castings offer two versions, LA and Magnum, and the Magnum style heads were chosen for this engine. Once received, Hughes installed their swirl-polished, stainless steel 2.02-inch intake and 1.62-inch exhaust valves, and treated the heads to their proprietary multi-angle valve job and slight bowl blending, but no extensive porting. The heads were topped with Hughes Engine's new 1.65 ratio shaft-mounted roller rocker arms, which require no girdle since each pair of rockers is mounted on an individual shaft.

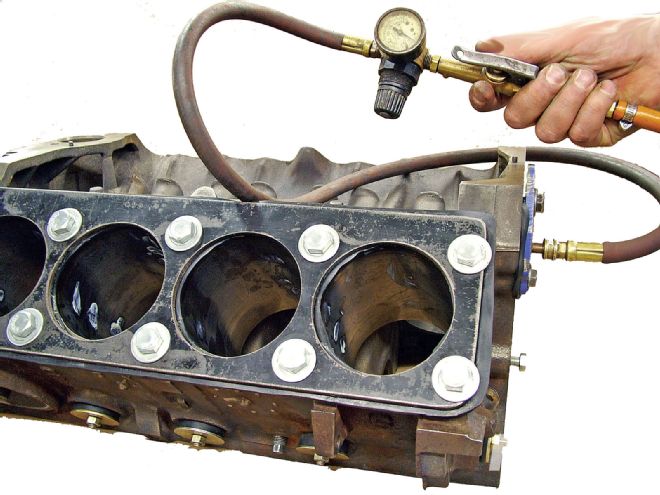

Pressure testing a block can find cracks that don't show up during magnetic particle testing. Hughes pressure tests all blocks used for performance builds to 30 psi.

Pressure testing a block can find cracks that don't show up during magnetic particle testing. Hughes pressure tests all blocks used for performance builds to 30 psi.

Choosing a camshaft for any engine should be a well-thought-out process, and a supercharged engine is no exception. While small displacement engines like the 318 normally respond to less lobe separation, shorter duration and higher lift camshafts, supercharged engines generally require a wider lobe separation and not so much lift and duration, making an engine that idles more smoothly with better low-end throttle response. Knowing these parameters, Dave installed one of Hughes Engines' HEH2332AL flat-tappet camshafts with a 113-degree lobe separation, 223-degrees intake and 232-degrees exhaust duration at .050-inch lift. The cam's lift numbers are .556-inch intake, and .589 exhaust lift at the valve with their 1.65 ratio rocker arms. With the pieces in place, the 318 was assembled, broken in, and inspected before being shipped to the Supercharger Store where it would be dyno'd first without, and then with the ProCharger-based Supercharger Store kit installed.

Once at the Supercharger store, the engine was fitted with a Holley 750 cfm carburetor and off the shelf tti step headers and the ProCharger D-1SC supercharger and water injection kit was installed but left inoperable for the moment. Purchasing ten gallons of the cheapest 91 octane fuel they could find on the way to the dyno, the engine was then taken to Larry's Engine and Marine in Tucson, Arizona, for its initial testing. While Dave Hughes predicted the small-block would make around 360 horsepower normally aspirated, the little 318 actually did better, making a best pull of 370 horsepower at 5,800 rpm, with 349 lb/ft of torque at 4,900 rpm, at only 30 degrees of ignition timing. With the baseline established, Bob Woods and his team from the Supercharger Store quickly installed the belt on the ProCharger and filled the water injection system reservoir. Since the additional air flow would require more fuel, a special 750-cfm Holley "blow through" carburetor was installed as well.

Combustion chamber seal is important in any high-performance engine, especially when a supercharger will be used....

Combustion chamber seal is important in any high-performance engine, especially when a supercharger will be used....

After firing up the engine and verifying it was running properly, the ignition timing was backed down to 28 degrees total advance for the first dyno pull with the supercharger pumping. Unfortunately, the 318 wouldn't idle at that low setting due to the initial timing being at zero degrees, so the factory Chrysler distributor was removed and modified to increase initial timing. With this modification performed, the now supercharged 318 idled cleanly at 900 rpm with 12 inches of manifold vacuum, and was deemed ready for dyno pulls.

With Bill Rohlinger of Goal 45 Motorsports assisting Larry's Engine and Marine with tuning and dyno testing, the 323-inch 318 netted 630 horsepower at 6,000 rpm on its initial pull. With some additional tuning, and by adding timing two degrees at a time until reaching 34 degrees total advance, the engine responded nicely and made additional power with each subsequent dyno pull. On its best pull, with 14.59 psi of boost and 34 degrees of timing, the 318 produced 662.7 horsepower at 6,000 rpm, and 587.5 lb/ft of torque at 5,800 rpm. To ensure durability, the engine was pulled three times in this state of tune, producing nearly identical numbers on each pull. Though just shy of their peak torque goal of 600 lb/ft, the engine hadn't yet peaked during this test session and likely would have made this number with simply another bump in ignition timing.

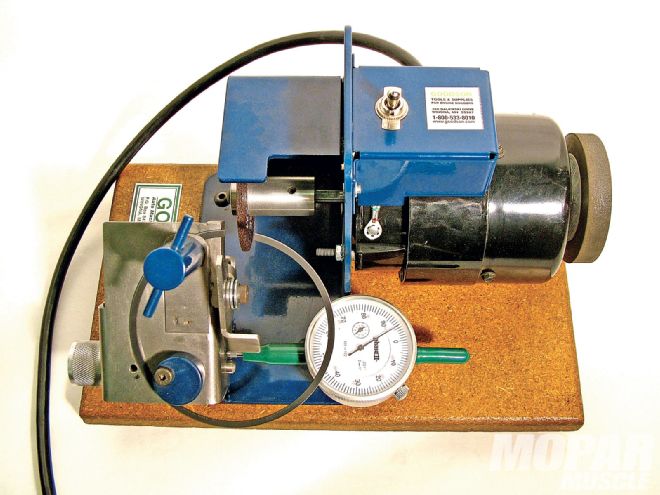

....Hughes files each ring to the cylinder, with extra gap in the bottom ring to prevent pressure buildup between the rings.

....Hughes files each ring to the cylinder, with extra gap in the bottom ring to prevent pressure buildup between the rings.

Overall, we'd say Hughes Engines and The Supercharger Store definitely met their goal of building a small-block that would equal or better the power numbers of a normally aspirated, stroker big-block on pump gas. Had the engine been based on the more popular (but less available) 360 small-block Mopar, the torque would have certainly gone up considerably, easily topping the 600 lb/ft mark. With 305 lb/ft of torque at a low 2,400 rpm, this engine should launch a car of moderate weight reasonably well, even without the benefit of a loose converter or high rear gear ratio, and with nearly 600 lb/ft of peak torque and over 660 horsepower on tap, this little 318 would make any Mopar a fun ride, proving that there is, in fact, a replacement for displacement! Be sure to watch future issues as we plan to install this engine in a '73 Plymouth Scamp for some real-world track and road testing.

Comparing apples to oranges

This month we learned how a mildly modified 318 compares to itself in normally aspirated, and supercharged, form but how does the 318 in this build compare with normally aspirated engines built specifically to make high power on pump gas? Judging by the numbers posted by the most powerful big- and small-block engines in our recent Amsoil/Mopar Muscle Engine Challenges, we'd say this 318 compares very well.

While there is something to be said for making big power without the benefit (or complication) of a "power-adder" like a supercharger, turbo, or nitrous oxide, normally-aspirated engines making big horsepower typically must be revved higher, requiring far bigger camshafts, much looser torque converters, and steeper rear gears to get their power to the pavement. So, with reliable supercharger kits available for nearly every conceivable Mopar these days, more enthusiasts seem to be choosing this option. Which is right for you? Here are some comparison engines with horsepower and torque numbers to help you decide.