When Oscar Jackson retired in 2003, having licensed his legendary Jackson Racing tuning company that specialized in supercharging Hondas and Miatas for 15 very successful years to Moss Motors, his plan was to kick back and enjoy the good life in Colorado with his family. Then, while on a trip to Europe, including a visit to the Isle of Man for its famous TT race, he came across a new technology that lured him out of retirement. That technology is the Rotrex traction drive supercharger, and in Oscar’s own words, “This is the tool I’ve been waiting for my whole life. With the Rotrex, all of the deficiencies I’ve experienced with turbochargers and superchargers over the last 30-plus years in the business were suddenly and very elegantly addressed.”

|

Rotrex Traction Drive

|

Rotrex Traction Drive

The technological starting point for Rotrex superchargers dates back to the early ’70s, when Anders Kolstrup, the company’s current technical director, began looking for improvements in engine development and performance as part of his hobby as a racer. Many years later, in 1996, the first Rotrex-related patent was issued and in 2000 the Copenhagen, Denmark-based company was established. But what’s so special about Rotrex and its patented traction drive technology that it pulled a supercharging legend like Oscar Jackson out of retirement, attracted Ferrari super-tuner Novitec Rosso and found its way onto the world’s fastest car, the 1,018hp Koenigsegg CCXR?

Visually, Rotrex superchargers look a lot like conventional centrifugal superchargers, both of which use a compressor side similar to that of a turbocharger (a compressor housing and impeller that connects to the main shaft). Rotrex superchargers are beltdriven, just like a standard centrifugal blower, so boost pressure increases with engine speed (since the pulley on the supercharger is spun by the main accessory belt that is powered by the crankshaft pulley). However, unlike conventional geardriven centrifugal superchargers that build comparatively little boost at low engine speeds because they have insufficient impeller speed (up to a maximum of about 70,000 rpm), Rotrex’s patented traction drive system can achieve impeller speeds up to 250,000 rpm, allowing the use of a smaller compressor wheel (sized more like a turbocharger compressor wheel) that operates within its optimum efficiency range more quickly and consistently.

But how are higher shaft speeds, greater efficiency and smaller packaging possible? It is the “planetary drive” with its patented “ramp effect” that make the Rotrex so special. These three planetary rollers are fixed in place 120 degrees from each other. They are enclosed within an annulus or “drum” that is turned by the input shaft via the serpentine drivebelt.

|

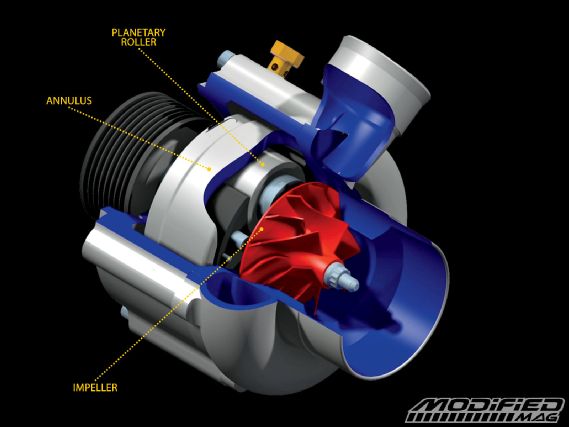

The cutaway image of a C30 Rotrex supercharger shows you some of its inner workings, including the turbo-like compressor side that houses the impeller, and the unique planetary drive side including the annulus or outer drum and the smaller inner planetary rollers that spin the impeller shaft at very high rpm.

|

The cutaway image of a C30 Rotrex supercharger shows you some of its inner workings, including the turbo-like compressor side that houses the impeller, and the unique planetary drive side including the annulus or outer drum and the smaller inner planetary rollers that spin the impeller shaft at very high rpm.

According to Oscar, “If you consider that the annulus/drum, planets and compressor shaft are all just smooth steel parts spinning on themselves without gears, it makes sense that at some point when there is a high load from the compressor making boost that these parts are going to slip on each other [causing inconsistent torque delivery]. But the ramp effect keeps this from happening. One of the planets is actually allowed to move slightly from its fixed bearing position. As the annulus/drum rotates, it exerts load onto the planets such that one planet is allowed to rotate slightly loose from its normal position. This loose planet then exerts a downward load onto the compressor shaft and the compressor shaft then loads up against the other two planets, preventing slip and keeping the torque consistent from low-load to high-load conditions.”

The relative size of the annulus/drum and planetary rollers inside it is how a Rotrex supercharger creates its very high overdrive and compressor shaft speed. In Oscar’s words, “When the annulus/drum rotates, its larger surface area moves across the smaller planets, accelerating the speed of the planets in the process. These planets in turn have a greater surface area than the output shaft that turns the compressor wheel. It is these two multiplication factors that give the Rotrex its high overdrive ratio.” This makes overdrive factors as high as 12.7:1 possible, compared to most centrifugal superchargers that run at overdrives of 2:1 or 3:1. What this means is that if a supercharged engine makes 10 psi at maximum rpm, the Rotrex-powered engine will have more than four times the airflow up to the point where both superchargers make the same 10 psi of boost. So it’s the high overdrive system that allows the Rotrex to use smaller, more efficient low-pressure ratio compressor designs, very much like a turbo would use, making it easier to install in the tight engine bays of today’s sport compact machines.

|

Here’s how complete the KraftWerks S2000 Rotrex-based supercharger kit is, including a Laminova water-to-oil cooler (the most efficient cooler money can buy), oil cooler lines with aircraft-quality AN fittings, OE-quality brackets and a brilliantly engineered timing belt tensioner that ensures reliability of the serpentine belt system.

|

Here’s how complete the KraftWerks S2000 Rotrex-based supercharger kit is, including a Laminova water-to-oil cooler (the most efficient cooler money can buy), oil cooler lines with aircraft-quality AN fittings, OE-quality brackets and a brilliantly engineered timing belt tensioner that ensures reliability of the serpentine belt system.

But the advantages of Rotrex’s supercharger design don’t stop there. Because these are sealed units that have their own separate oiling system, there’s no need to tap the engine’s oil pan. This also means that, unlike a turbocharger, the Rotrex blower doesn’t tax the engine’s existing cooling and oiling systems, helping keep underhood and engine operating temperature under control. The big drawback to turbochargers, after all, is that they use the energy supplied by exhaust gases to power the compressor, the by-product of which is heat—and lots of it. According to Oscar, “The problem with all this turbo-related heat buildup and the fact that the turbo spools so rapidly at mid rpm levels without being controlled by the crankshaft, is that ECU tuners are forced to throw a ton of fuel into the combustion chamber and pull timing at the point of full spool to protect against detonation. With a Rotrex supercharger you can actually do the exact opposite, leaning out the [air/fuel] ratio and adding timing because the system runs so cool. As a result, you end up with improved fuel efficiency and more consistent and reliable power production.”

KraftWerks first brought its Honda S2000 supercharger kit, followed by several different kits including a Honda Fit kit, a Honda K-series race kit, a soon-to-be-released ’06–09 Honda Civic Si kit, and ’90–05 Mazda Miata and Nissan 350Z kits.

According to Oscar, the compact size of the Rotrex superchargers has allowed KraftWerks to develop some very elegant kits that require no cutting, drilling or other permanent alterations to the vehicle it’s being installed on. “My philosophy has always been to engineer my supercharger kits such that no cutting or drilling is required. We don’t take any shortcuts with our kits,” Oscar says, “because we want them to be straightforward to install as well as very reliable, providing OE-like characteristics with respect to driveability, fit and finish.”

To that end, the KraftWerks team has stress-tested all its kits in the most extreme environments, from the blistering heat of Death Valley, to the constant high rpm of the racetrack, to the high altitude and sub-zero temperatures of Colorado’s Rocky Mountains. The result of all this stress testing are CARB-friendly kits that come with a two-year warranty and provide incredibly efficient power gains across the engine’s entire rev range. All you have to do is look at the shape of the torque curve on a dyno plot to realize that Rotrex superchargers really are an evolution if not revolution to the forced induction options available to go-fast junkies like you and me. The torque curve on a naturally aspirated or turbocharged S2000 engine peaks early in the powerband and slowly drops off all the way to redline, giving the curve a flat and slightly declining shape overall. But with the KraftWerks high-boost S2000 kit, the torque curve climbs upward all the way to the rev limit, illustrating how efficient the Rotrex blower is and how boost builds with rpm in a beltdriven supercharger. But as you can see from the KraftWerks high-boost S2000 kit dyno plot, the torque curve climbs upward all the way to the rev limit (or close to it), illustrating the Rotrex blower’s tremendous efficiency.

|

Hondata’s land speed record-holding RSX went 234 mph with the help of a KraftWerks twin Rotrex supercharger setup.

|

Hondata’s land speed record-holding RSX went 234 mph with the help of a KraftWerks twin Rotrex supercharger setup.

With much higher compressor speeds than a conventional supercharger, and without all the engine-killing heat production or risk of boost spikes common in turbochargers, all in a very compact and low NVH (noise, vibration and harshness) package, there does not appear to be any downside to this amazing new blower. But just in case you need testimony from a third party, all you have to do is give the guys at Hondata a call and ask them how they enjoyed breaking three land-speed records with their 700hp, twin-Rotrex-powered RSX. In a sport where the turbocharged competitors tend to blow engines and driveline components regularly, the Hondata RSX ran with flawless reliability up to a mind-blowing 234 mph, thanks in large part to the linear power and low heat production of the twin Rotrex blowers KraftWerks bolted up to the built K20 engine. Which leads me to wonder, How fast could my K24 EG Civic go with a Rotrex or two under the hood? It might be time to find out!