| Coolin' Down With ARC - Garage.Tech

| Coolin' Down With ARC - Garage.Tech

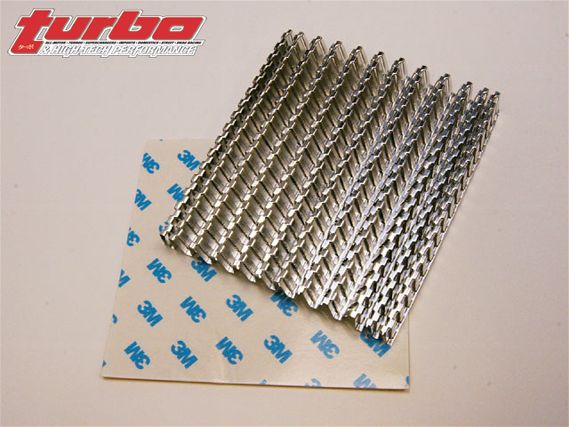

ARC International of Japan built their reputation within the automotive community as one of the top manufactures of high-performance products in motorsports competition, such as Formula Nippon, Super Taikyu and Super GT. Best known for their patented intercooler cores that allow for the most efficient temperature drop without loss of pressure, ARC recently shocked the motorsports world when they released arguably one of the most innovative yet controversial products to the market, the ARC Cool Fin. Designed by ARC engineers with a special high-thermal conductivity aluminum fin design, the Cool Fin can be affixed using the special 3M pad on temperature-sensitive areas like the oil pan, intercooler piping, differential and transmission (areas that are prone to excess heat and have no cooling system).

| The 3M thermal conductive interface pad offers excellent heat transfer and can be cut to a specific size using a razor blade or pair of scissors.

| The 3M thermal conductive interface pad offers excellent heat transfer and can be cut to a specific size using a razor blade or pair of scissors.

Before you come to the conclusion that ARC uses some typical run-of-the-mill foam padding that adheres to the Cool Fins, we did some investigative research on the 3M Web site and found some interesting information. The 3M pads provided by ARC are, in fact, a special thermal conductive interface pad made specifically to transfer heat. Used to dissipate heat, the silicone-elastomer sheet filled with thermally conductive ceramic particles offers flexibility and strength to hold products in place. In this case, the 1mm 3M thermal pads are supplied to securely attach the aluminum Cool Fins in place.

ARC representatives claim the technology and patent-pending design, which was recently debuted to consumers, was derived through race technology. While the theories of heat transfer taken from Rohsenow &Hartnett's Handbook of Heat Transfer states thermal conductivity of the aluminum is orders of magnitude greater than that of air. This means that heat transfer is going to depend entirely on the rate of airflow over your package surface and on its surface area. In essence, this theory backs up the claims of using the Cool Fin on areas like the oil pan, intercooler pipes, transfer case and rear differential that can subject that area and the fins to large amounts of airflow when driving at high-rated speeds as well as aid in thermal dissipation.

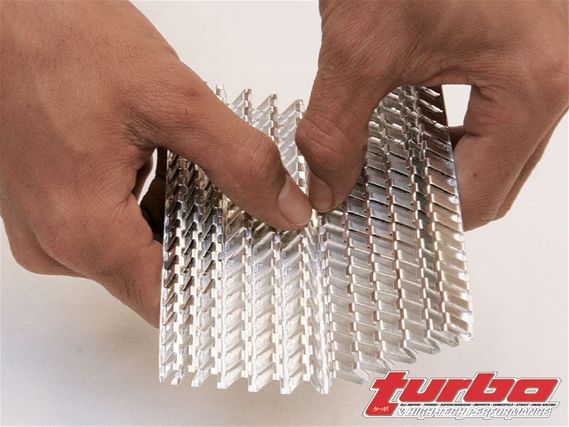

| The Cool Fin is flexible, making it easy to apply on rounded surfaces and non-flat surfaces.

| The Cool Fin is flexible, making it easy to apply on rounded surfaces and non-flat surfaces.

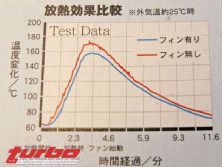

Equipped with a few sets of ARC Cool Fins, we took to the track in hopes of performing some before and after tests with the unit but experienced an unexpected sheering of the Evo's accessory belt, which sent us home packing in disappointment without any true numbers. Independent testing performed by various Japanese publications has shown the Cool Fins to work when installed on the vehicle. One test showed a drop in temp from 117 degrees C to 112 degrees when using the Cool Fin on their track-prepped DC2. While browsing the ARC Web site we found an independent test conducted using two heat detection monitors placed directly on a portable gas burner, one of which was encased with the Cool Fin while the other wasn't. After 14 minutes and 19 seconds, the non Cool Fin unit measured 155 degrees C on the pyrometer while the Cool Fin-encased unit was shown at an amazing 130 degrees C-a 25 degree difference in temp while exposed to direct heat.