The stock intercooler on the Cooper S looks more like a power steering cooler than something designed to support the performance driving the Cooper S is designed to evoke. One lap on the racetrack, a hot summer day, or increased boost levels can easily make this small and extremely under-engineered intercooler prone to heat soak, reducing power, economy, and most of all, fun. To help eliminate this pitfall we contacted Forge Motorsport, an industry leader in intercooler design, to help us out. And while we were at it we also decided to really test out the Cooper S’s newfound efficiency with NM Engineering’s Stage 2 software.

|

2008 Mini Cooper S - Proven

|

2008 Mini Cooper S - Proven

Vehicle Data

Engine: 1.6-liter I4, dohc, 16-valve, turbocharged

Transmission: Six-speed manual

Drivetrain: Front-wheel drive

Mileage: 15,917

Current modifications: NM Engineering Stage 1 flash, NME cat-back exhaust, NME Hi-Flow induction kit, NME discharge pipe, NME charge pipe

Dyno Data

Type: Clayton Mustang dynamometer with Virtual Test Track Software

Transmission test gear: Third

Dyno set weight: 3,300 lb

Fuel grade: 91 octane

Baseline

Temperature: 68F

Humidity: 11%

Peak power: 182 hp @ 6054 rpm

Peak torque: 200 lb-ft @ 2268 rpm

Test Notes

All horsepower and torque numbers are quoted at the wheels. It is also important to keep in mind that a properly calibrated Mustang dyno produces more accurate real-world horsepower and torque numbers. While these numbers might seem low when compared to a Dynojet, down roughly 10 percent, sometimes even greater if the dyno is miscalibrated, what is important is the differences between each dyno run. While the numbers matter, it is the differences between the runs that help prove or disprove the validity of the manufacturer’s horsepower and torque claims

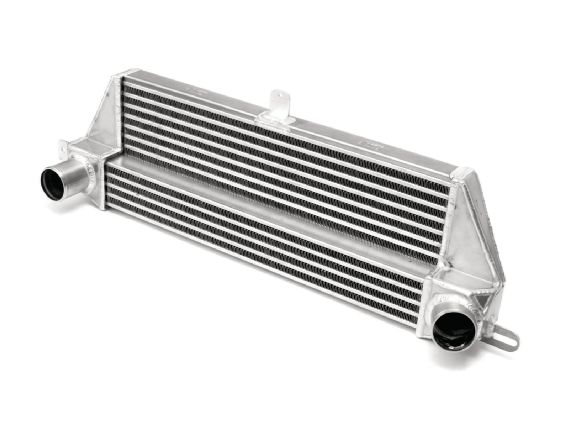

Forge Motorsport Uprated Alloy Intercooler

|

2008 Mini Cooper S - Proven

|

2008 Mini Cooper S - Proven

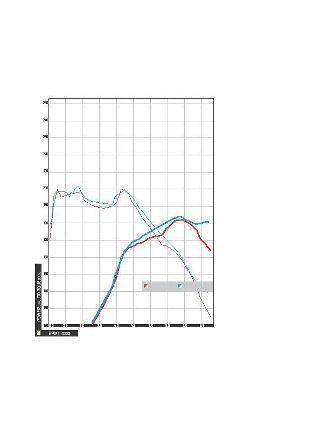

Test 1

Performance

Peak power: 184 hp @ 5922 rpm

Peak torque: 201 lb-ft @ 2889 rpm

Max power gain: 16 hp @ 6830 rpm

Max torque gain: 5 lb-ft @ 4750 rpm

Temperature: 70F

Humidity: 12%

Tools: T25 Torx driver, box cutter, flat-head screwdriver

Parts: Intercooler core, modified front bumper grille

Installation time: 1.5 hours

MSRP: $720

Pros

Direct bolt-on with only minor trimming of the front bumper cover

Reduced intake temperatures

Intercooler core bolts to the factory mounting tabs

Dual-core construction maximizes efficiency in a limited space

250% larger surface area and a 125% thicker base core

|

Peak Torque: 201 lb-ft

|

Peak Torque: 201 lb-ftPeak Power: 184 hp

Temperature: 70°F Humidity: 12%

Cons

Intercooler core does not appear centered in lower grille opening

The air intake graph represents the difference in temperature levels, between the stock intercooler and Forge Motorsport intercooler. Intake temperature and rpm data used in the graph was extracted from the ECU with Bavarian Technic USB OBD-II cable and software. The temperature data was converted from C to F using a mathematical conversion formula.

Nm Engineering Stage 2 ecu flash

|

2008 Mini Cooper S - Proven

|

2008 Mini Cooper S - Proven

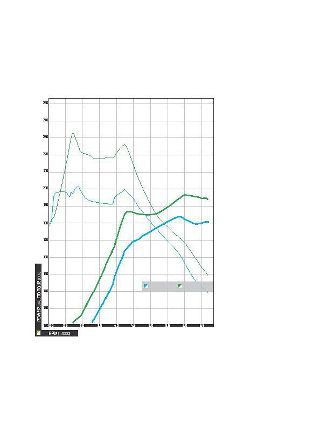

Test 2

Performance

Peak power: 197 hp @ 6133 rpm

Peak torque: 233 lb-ft @ 2738 rpm

Max power gain: 15 hp @ 6151 rpm

Max torque gain: 35 lb-ft @ 2738 rpm

Temperature: 71F

Humidity: 12%

Install Process: OBD Port Flash

Installation time: 25 minutes

MSRP: $500

Pros

Completely reversible with zero physical modifications

Retains all of factory safety protocols

Free lifetime upgrades and free re-flash back to stock programming

100% compatible with all diagnostic software

Fuel, timing and electronic throttle settings have been optimized to take full advantage of the increase in boost pressure

Sport button retains full factory functionally

|

Peak Torque: 233 lb-ft

|

Peak Torque: 233 lb-ftPeak Power: 197 hp

Temperature: 71°F Humidity: 12%

Cons

None

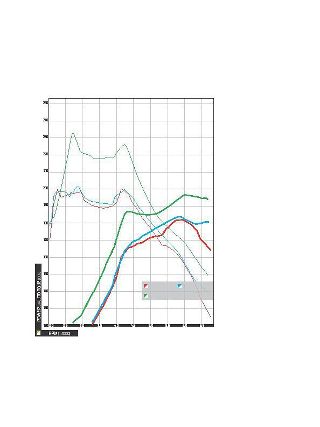

Conclusion

|

Max Torque Gain: 40 lb-ft

|

Max Torque Gain: 40 lb-ftMax Power Gain: 28 hp

The engine’s intercooler and turbocharger are two components that, when properly balanced, generate consistent power and performance. The MINI Cooper S’s stock system is a perfect example of how an imbalanced system can result in inconsistent power and decreased performance. On the dyno, the stock Cooper S power curve is very inconsistent with an intake temperature that more than doubles as the engine moves through the rpm range, resulting in excessive timing retard and power loss. The Forged intercooler corrected the system imbalance and run after run on the dyno the power and the intake temperature stayed consistent. On the road the Forge-equipped Cooper S no longer seemed to give up in the upper rpm range, pulling solid all the way to redline. For good measure we decided to try the NM Engineering Cooper S Stage II higher boost software that recommends a upgraded intercooler, especially when using 91 octane. The result is more power and more fun, and the Forge intercooler was still able to maintain balance. If you own a Cooper S, adding an uprated intercooler in a must.

Costs Summary

Forge Intercooler

$720.00

NM Engineering Flash

$500.00

MSRP total.

$1,220.00