| A drop-in K&N filter was a very impressive, easy to install, huge bang for the buck mod.

| A drop-in K&N filter was a very impressive, easy to install, huge bang for the buck mod.

The EVO is a known commodity in the tuning world. It seems that wherever you look you see them; it also seems that spotting a stock EVO anymore is about as likely as spotting a flock of Ferrari Enzos. The EVO IX was the final evolutionary development of the superb, destined to become classic CT9A chassis, which also includes the IX's predecessors-the VII and VIII. The IX's defined by the changes its legendary 4G63 engine's undergone, bettering it year by year.

| The K&N filter versus stock filter dyno comparison reveals impressive gains for such a simple part.

| The K&N filter versus stock filter dyno comparison reveals impressive gains for such a simple part.

The 4G63 is known more for its rock solid strength than it is its technological superiority. Its stout iron block and DOHC valvetrain have become somewhat dated as this engine traces its ancestral roots back to the mid-1980s. But in its last year of production, Mitsubishi face-lifted the 4G63 with a bit of modern technology. The biggest difference in the IX's engine is MIVEC, Mitsubishi's variable cam timing system. MIVEC allows for 27 degrees of intake camshaft adjustment, which ultimately helps improve the 4G63's powerband. Intake camshaft timing is kept retarded at lower engine speeds, which results in reduced overlap, making for a smoother idle and improved emissions. Camshaft timing then increases alongside engine speed, making for improved torque and quicker turbo spool-up in the midrange. But at high-engine speeds timing is once again retarded in order to reduce backpressure-driven reversion to promote better breathing.

The new cylinder head features enlarged water jackets surrounding the combustion chambers making extended thread spark plugs mandatory. This improves combustion chamber cooling and reduces the chances of detonation. This makes for more aggressive tuning with our poor quality pump gas and means power output remains more consistent, an issue that plagued the EVO VIII. These changes help make the IX more responsive to tuning when compared to the older VIII resulting in fewer compromises throughout the powerband.

| The GReddy TiC cat-back exhaust system features lightweight construction and large, 80mm diameter piping, giving us ample wiggling room for future mods.

| The GReddy TiC cat-back exhaust system features lightweight construction and large, 80mm diameter piping, giving us ample wiggling room for future mods.

As Project EVO's been making its way toward racking up its first 1,000 miles, we've been itching to get into its engine. Before our initial dyno tests, we changed all of our fluids to Motul synthetics to help protect our investment. Engine oil consists of Motul's 300V 15W50 and the gear oil 300V 90W140. Motul's synthetics are race-bred, used by top race teams like Nismo's JGTC effort and Subaru's WRC rally team, so we're pretty sure they're good enough for us. Synthetics work better during high-heat applications and are less likely to choke, just what's needed for hot-running turbo engines. On a side note, we also replaced Mitsubishi's fish oil brake fluid with Motul RBF 600. The RBF formula is of the best around, performing nearly as well as or better than many ber-expensive exotics like the legendary F1 standards: Castrol SRF and AP550. Motul's dry boiling point is an astounding 600 degrees F-amazing. Motul also resists absorbing moisture from the atmosphere better than most brake fluids do, resulting in a higher boiling point than many of its competitors.

| The TiC exhaust has few bends for the least amount of turbulence and backpressure.

| The TiC exhaust has few bends for the least amount of turbulence and backpressure.

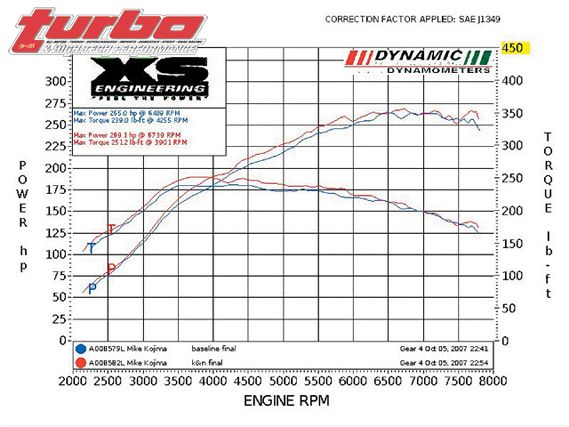

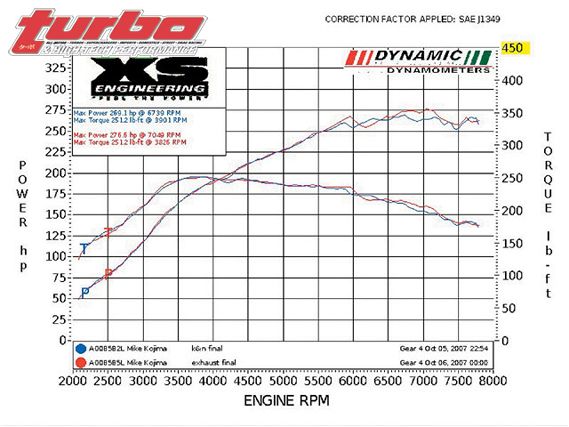

Even in stock trim, the differences between the VIII and IX are readily apparent. Turbo lag is less of a problem with the IX, while low-end torque is more readily available and power doesn't taper off as quickly as the VIII at higher engine speeds. Project EVO's baseline dyno results at XS Engineering revealed consistency run after run, quite the contrast from our rather erratic EVO VIII project from a few years back. In stock form, Project EVO IX surprised us with a healthy 265 whp at 6,500 rpm and 239 lb-ft of torque at 4,250 rpm; a whopping 38whp gain from the old EVO VIII project.

| TiC exhaust system versus stock EVO system: Gains are mostly at the top end.

| TiC exhaust system versus stock EVO system: Gains are mostly at the top end.

Our first mod is one of the biggest bangs for the buck we've witnessed. We simply flipped our stock airbox lid and dropped in a K&N replacement air filter element. The K&N uses a washable and reusable cotton gauze element that flows much better than the OEM oiled paper part ever could. K&N assured us our replacement filter was going to surprise us but we remained skeptical. We were amazed to pick up 4 whp at the peak, resulting in 269 whp at 6,740 rpm. The filter also allowed for increased power throughout the powerband, as much as 8 whp in certain spots.

Next up is our cat-back exhaust. Now just about every EVO in these parts sports some sort of cat-back exhaust, in fact we can't remember the last time we've seen an EVO without one. Since Project EVO's modifications will inevitably get rather extensive, a large diameter exhaust was chosen. And since we also plan on tracking our all-go no-show EVO, weight became a consideration; after all, the EVO is somewhat porky to begin with, with an exhaust that isn't exactly light. Enter GReddy's TiC system.

The TiC features big 80mm tubing, one of the only non-special order exhausts available in the U.S. to offer such sizing. The EVO TiC is designed with minimal bends for less backpressure and better exhaust velocity. It's also light, featuring thin-wall stainless steel construction, hollow stainless hangers, thin but strong stainless flanges and a titanium tip. The TiC exhibits extremely low backpressure with its straight-through perforated core mufflers filled with GReddy's unique composite cube packing. The TiC is more than 20 pounds lighter than the stock exhaust. What we found amazing was that despite the system's race-inspired, straight-through construction and baffle-free mufflers, it was nearly as quiet as the stock muffler-that's with the optional silencer removed. On the dyno we found that the TiC gave us 8 hp on the top end boosting our output to 276 whp at 7,050 rpm. The exhaust was limited to power increases up top, which leads us to believe that major restrictions lie forward of the cat.

Next up is XS Engineering's intercooler hard pipe kit. The kit replaces the restrictive stock piping with smooth, mandrel-bent polished aluminum tubing. It works with both the stock and XS' upgraded front-mount intercooler. A smaller battery, however, is required when using the XS kit-or you can do what we did and relocate the battery to the trunk. A smaller or relocated battery allows XS' hard pipe kit to take advantage of smoother bends for less turbulence inside. It's apparent XS took their time here, carefully shaping and routing pipes to keep bends at a minimum and airflow high without simply resorting to larger tubing, which often leads to poor throttle response and increased turbo lag.

The hard pipe installs relatively easily but we did have to remove Project EVO's front fascia-also an easy job. It's almost as if the EVO was designed to have its bumper easily removed. XS assured us that the power gains would please us but, again, we were skeptical. We just didn't think the stock intercooler plumbing was all that restrictive looking. A trip to the dyno yielded surprising results. The XS piping resulted in a 7whp gain for a new high of 284 whp at 6,800 rpm. Power gains were generally across the board with improved low-end response. Peak gains of more than 12 whp were realized past peak power. What a pleasant surprise this was.

| Intercooler outlet to throttle body as installed.

| Intercooler outlet to throttle body as installed.

It's a well-known fact that the Karman mass airflow meter-equipped EVO is sensitive to change. Even simple modifications can play havoc with air/fuel ratios as the MAF can easily be thrown out of whack. Usually, ECU tuning is required to get the most out of any modification, especially when dealing with modifications positioned pre-turbocharger. Another issue: factory timing maps are optimized for 93-octane gas and are just too aggressive for our crappy California 91-octane pee water. The EVO ECU monitors knock; as knock counts rise, the ECU pulls timing. And if they get too high, the ECU switches to less aggressive high-octane and even several different low-octane maps to better protect the engine. This makes for inconsistent operation.

Mitsubishi's ECU tune fails to take advantage of all MIVEC has to offer. With a full 27 degrees of intake camshaft adjustment possible, the stock system only makes use of roughly half that. Large low and midrange power gains can be had through MIVEC tuning. All is likely this way for emissions reasons.

XS Engineering's Koji Arai fired up his laptop for a quick ECU reflash using their stock vehicle/cat-back exhaust program. The XS flash tweaks fuel, ignition, MIVEC maps, boost control tables and raises the rev limit to 7,800 rpm. One advantage with ECU reflashing versus piggyback systems is that the former does what it does in the same way the factory gets things done. With piggyback devices, Mitsubishi's ECU is forced into a figurative tuning fight with the piggyback ECU, automatically adjusting fuel and spark trims that are constantly trying to return to normal parameters. Because of this, inferior piggybacks can often run well at first and then begin to conflict with the ECU resulting in poor operation. On an aggressively tuned setup this isn't just annoying, it can also be potentially dangerous for the engine's health. Another advantage to reflashing the stock ECU is that all of the factory's electronic safeguards for overboost, knock detection and overheating remain intact.

| Intercooler inlet pipe as installed.

| Intercooler inlet pipe as installed.

Back at the dyno, XS' reflash results were amazing. We gained 5-peak hp, which means Project EVO's pumping out a good 289 whp at 7,100 rpm. This only tells a fraction of the story, though. Power gains are huge across the board, as much as 18 whp in certain spots. We picked up power from idle all the way to fuel cut. Each power curve dip and squiggle was filled in nicely with hardly any drop at all as we approached fuel cut. The results are a solid wall of power from 3,000 rpm all the way to 7,800 rpm-a whopping 4,800rpm powerband. On the road, the car feels like a different animal with the turbo spooling much faster and always wanting boost. The seat of the pants feel is even greater than dyno charts would suggest. On a side note, we believe XS' reflash to be extremely safe, perhaps even safer than the stock program as knock counts are fewer and dyno pulls are far more consistent. Had we known about all of these positive benefits, we would have probably flashed the ECU as a first step. The XS reflash was, by far, the best thing we have done to date.

Overall, Project EVO pleases us. With a few simple bolt-ons and our ECU reflashed, we picked up nearly 30 whp across the board from idle to fuel cut. Project EVO currently feels exactly how we believe it should feel straight from the factory. Stay tuned; we'll be working on our IX in an effort to find out how far we can push it with its stock turbo and even more simple bolt-ons.