Water/methanol injection remains a popular upgrade within the high performance automotive market. It's hard to believe that injecting water and anything else into an engine in the quest for more power can actually be a good idea, but the truth is that water/methanol injection is beneficial to all forcibly induced and naturally aspirated engines-if done properly. The main function of water/methanol injection is to prevent detonation, but that's not to say it can't also increase horsepower/torque output by 10 to 15 percent with proper tuning.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

What is Methanol?

Methanol is an alcohol compound comprised of one carbon atom, one oxygen atom, and four hydrogen atoms (CH3OH) and is also referred to as wood alcohol, carbinic acid, and methyl alcohol. This poisonous, flammable, and relatively volatile liquid is naturally occurring, and domestic uses date as far back as the third millennia B.C., when Egyptians used methanol in their legendary embalming processes. It was first synthesized in the 1600s, and was later combined with water and used during WWII in supercharged fighter planes and bomber engines. After a few fast years, it was even banned in both F1 and NASCAR in the '60s for adding too much power to competition engines.

How does it work?

Simply put: it helps prevent detonation. Substances heat up when they're compressed, and in traditional gasoline engines, detonation-or "pre-ignition"-occurs when a cylinder's air/fuel charge compresses and heats to the point of auto-ignition during the compression phase, before it can be lit at the proper time by a spark plug. If this occurs a few degrees of crank rotation in advance, the consequences may not be bad. But if it occurs farther back in the compression stroke, in high-horsepower instances, it can easily destroy an engine's internal components. Water/methanol injection systems deliver a finely atomized mist of a water/methanol mixture to an engine's cylinder charge, and as the mixture absorbs heat and vaporizes, temperatures inside the cylinder are reduced and the propensity for detonation is decreased. Today's newer, knock-sensor-equipped vehicles are very good at staving off detonation by retarding ignition timing the moment detonation-also known as "knock"-is detected, but do so at the cost of severely decreased power output and fuel economy.

While water is not combustible, it has a greater capacity to cool intake charges than methanol alone. This is why most manufactures recommend that a 1:1 mixture of meth and water be injected into your engine. Methanol also effectively increases the octane rating of fuel, giving the benefits of running higher octane levels. The evaporative effects of the water, plus the octane boost of methanol, allows your motor to run more advanced ignition timing and/or boost to create additional horsepower with proper tuning. A general rule of thumb is that an engine will output one percent more horsepower for every 10 degrees intake temperature is decreased. Many enthusiasts have found the benefits of using water/methanol injection equivalent to running race gas, but without the $12/gallon price tag.

With dozens of methanol injection kits sold on the market today, we headed over to SoCal tuning gurus HB Speed in Huntington Beach, CA, and tested the Devilsown DVC-30 Stage 2 kit on an '06 Mitsubishi EVO IX SE. While many of their competitors' kits use parts commonly found at local hardware stores, Devilsown designs each component to work specifically with each of their methanol kits to provide long-term reliability. From their nozzle holder that reduces internal turbulence, to tank adaptors with built-in filters, to their progressive methanol controllers designed specifically for boosted applications, Devilsown takes the fear out of using water/methanol injection, enabling your engine to run more boost and timing to maximize power.

The Devilsown DVC-30 electronic progressive controller is the brain of the system, and converts from MAP voltage to a boost value to initiate the water/methanol pump when adjusted using the dial settings. When boost pressure reaches a pre-determined level, the pump activates at 15 percent duty cycle and then ramps up in keeping with boost to deliver a linear response curve. As a safety feature, the controller can quickly shut off the pump when boost pressure drops below a certain threshold, to prevent misfire or engine damage. The progressive controller's compact design was intended to be mounted inside a car, for easy adjustment of the system on the fly, with no need to pop the hood or use screwdrivers to adjust the knobs.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

This 250psi variable-speed pump is marketed as the highest-pressure pump on the market. This high-pressure pump ensures the spray nozzles emit the smallest droplets possible for peak atomization. The DVL-8031 pump's unique design enables it to run dry without damage, and includes a built-in reverse check valve to protect its internal components for longevity.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

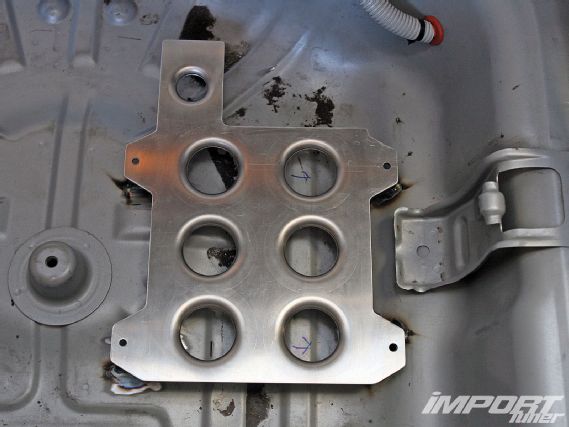

M1 Fabrication and Development, located in Brea, CA, custom fabricated a bracket to secure the 2.5-gallon tank in the trunk of our EVO IX.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

Clogged nozzles are the primary cause for water/methanol injection failure. Devilsown designed their methanol tank fittings with a cone-shaped screen that is placed outward, against the flow of the water-methanol mix, to deflect nozzle clogging.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

When used with the DVC-30 controller, an optional self-sealing float switch activates an LED warning system to warn when the water/methanol has reached low levels.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

Devilsown compression fittings are designed with interlocking teeth to allow pressure hoses to be connected with a simple push, or disconnected by sliding a tab, for a water-tight seal.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

We opted to install an optional Devilsown upgrade package, consisting of three feet of high-pressure nylon hose, fittings to relocate the check valve before the "Y" union, and additional parts to run a dual-nozzle setup.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

Removable, screw-in 80-micron filters allow for easy cleaning and excellent filtration. The nozzles are nickel plated to protect from methanol corrosion for increased lifespan. Each spray nozzle is designed with built-in O-rings to prevent leakage. Determining the correct nozzle size will depend on engine displacement, type of kit, pressure of pump, and horsepower, but can also be determined by using the Devilsown nozzle calculator, located on their website (given at the end of this article).

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

Devilsown's 2.5-gallon tank is the first water/methanol tank with a built-in sump and fluid control baffle. The sump design eliminates pump starvation under hard cornering, while the baffle reduces liquid "sloshing" during sprinted driving. The tank is made with 1/4-inch-thick HDPE, which is the same material and construction common to most racing fuel cells.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

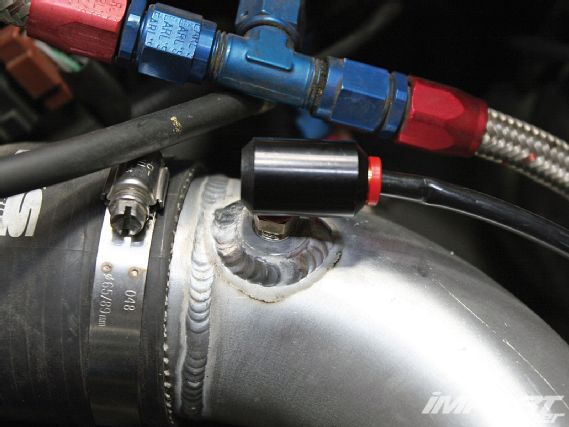

M1 Fabrication and Development welded two bung fittings onto our charge pipe. We positioned one nozzle in front of the throttle body, with the other mounted directly after the blow-off valve.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

The Devilsown water/methanol delivery jet in action.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

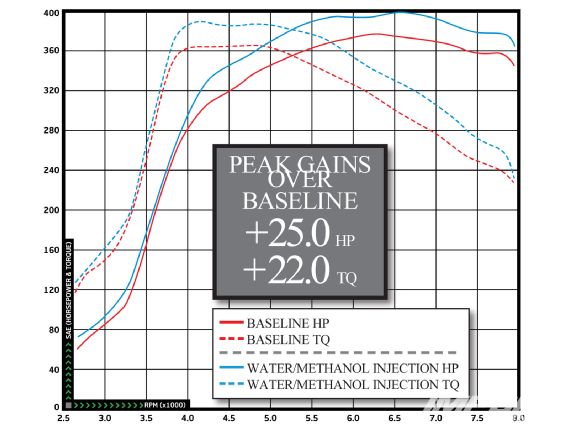

The production of more power by a water/methanol-injected engine is not a product of the water/meth mixture alone. You must tune to get the most out of it. Our EVO IX-equipped with a Tomei Arms M7960 turbo, Cosworth M2 camshafts, Cosworth CNC-ported head, Okada Projects Plasma Quad Pac, and full Fujitsubo exhaust-dynoed a baseline of 375 hp and 364 lb-ft of torque.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

Upon dynoing the EVO with the Devilsown kit installed, we found that the octane-boosting effect of the water/methanol mixture mirrored tuning a car with race fuel. The water/methanol injection enabled us to run the same air/fuel ratios as a pump gas tune, but with less fuel added to the map of our engine management software. Tuning with water/methanol injection, we typically ended up with the same air/fuel ratios common to pump-fuel tunes, but with less fuel needed, and the benefits of increased knock resistance. We were able to add timing and boost from 3,800 rpm to redline, and made 400 hp and 386 lb-ft of torque. Although we could have made even more power over our baseline, the goal was to use the water/methanol injection to safeguard the motor when driven under extreme track temperatures and strenuous road racing, rather than simply going for maximum power.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

10 Things You Should Know About Methanol Injection, But Were Afraid To Ask.

By Chance McClurkin, of Devilsown

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

1) What gains can be expected from water/meth injection?

Depending on the current setup of your car, the type of car, and your tuner's ability, all mods are best realized with some sort of aftermarket tuning-the same theory applies to water/meth injection. But generally, gains of 25-45 hp and as many lb-ft of torque are common, making methanol injection one of the best bang-for-the-buck power upgrades for your car.

2) Can water/meth injection damage my engine?

With most aftermarket parts there's always the possibility of damage, but not if the unit is installed and used properly. As long as the injection system is working properly, it can only do good things. Since the water and methanol will help dissolve carbon buildup, it can keep your spark plugs, valves, and combustion chambers very clean, too.

3) Can you run just water injection without methanol?

Yes, but you will not be able to take advantage of the octane-boosting properties of methanol, thus you will get cooling from the water, but no increase in octane. Without methanol, you may not make as much power.

4) We've shown how a turbocharged car can benefit from using water/methanol injection, but can it be used on naturally aspirated cars as well?

Yes, it can be used on N/A applications. Generally, it's used when someone needs more octane or is having problems with detonation.

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

5) What are the most important issues when setting up a methanol kit?

The most important issue is proper nozzle sizing. It's far too common that people go off the "if a little is good, more is better" mentality-which is why we recommend a 1:1 ratio of water and methanol. The motor can only ingest so much water in the combustion chambers before it loses horsepower.

6) What supporting upgrades are required for water/methanol injection?

At minimum, you should have some sort of engine management that can be tuned to adjust timing, boost, and fuel curves to compensate for the octane boost and cooling effects. You do not need an aftermarket intake, exhaust, intercooler, or strengthened internals. Although, with more supporting mods, more power can be made.

7) Is a high-psi pump necessary to feed methanol? Why not use the factory windshield wiper pump?

Water/methanol must be injected above 60 psi to properly atomize into the engine. Pressures lower than that will reduce the cooling effects, since the larger droplets exiting the low-pressure pump reduce total surface area, and will cause little to no gain in performance.

8) How long will a two-quart tank last?

In high boost/high horsepower applications, a quarter-mile run will use as much as 1/8th of a tank. A larger tank should be considered if boost pressures of over nine psi are utilized in road racing, where a two-quart tank will run dry in as few as five to six two-mile laps. Under normal street use in a 400hp car, a two-quart tank will usually last about 450 miles.

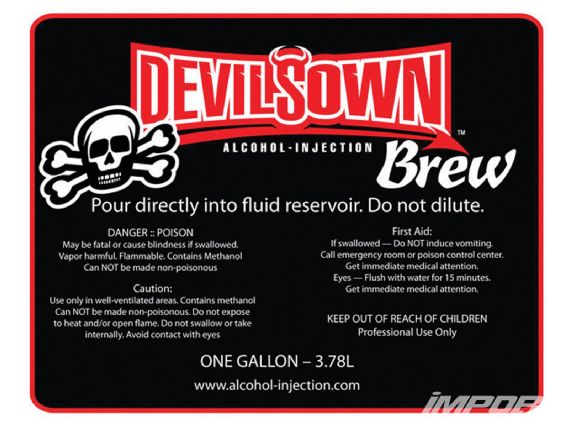

9) Can I use windshield washer fluid?

Most wiper fluids contain some sort of glycol or detergent that can clog your nozzle. We recommend our proprietary methanol blend: Devilsown Brew. Not only does methanol improve your fuel quality, it will also give you a better intercooling effect in the inlet tract. Denatured alcohol can be used, but we strongly advise our customers to use methanol for better, more consistent performance.

10) At what boost level should one introduce water/methanol?

Systems for superchargers or large turbo setups will deliver methanol at 50 percent of peak boost. Positive-displacement superchargers or fast-spooling turbos should inject meth at or near peak boost. Most engines are pretty tolerant of extra water vapor, up to a point of diminishing returns.

Where To Locate Your Water/Methanol Injection Nozzle

|

Water / Methanol Injection - Tech-Knowledge

|

Water / Methanol Injection - Tech-Knowledge

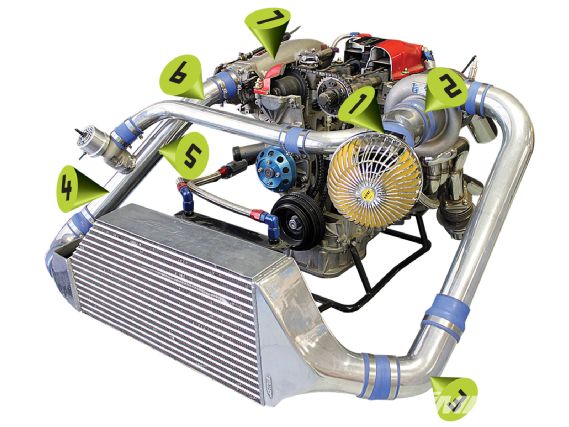

1. MAF Sensor

Make sure you do not place the nozzle in front of the mass air-flow sensor (MAF). Injecting water or methanol through the MAF sensor will likely cause it to short out.

2. Pre-Turbo

Locating the nozzle in front of the turbo chemically alters the turbo compressor map, causing a change in the engine's air/fuel ratios. Injecting water/methanol directly into the turbo can also damage the compressor blade.

3. Pre-Intercooler

Installing the nozzle before the intercooler might seem like the perfect location to aid in pre-cooling, but it does have its drawbacks. If the nozzle doesn't emit a fine enough mist, both water and methanol can condense and collect in the bottom of an intercooler core. In colder climates, the overcooling effect can cause the water to freeze inside an intercooler, causing a blockage of airflow. On the flipside, hot air from the turbo can prematurely vaporize the water by the time it reaches the intake, rendering the system ineffective.

4. Post-Intercooler

Most methanol installers prefer placing the nozzle before the intake air temperature (IAT) sensor typically found on newer vehicles. IAT sensors monitor the temperature of air going into an engine, and can automatically advance ignition timing and lean out air/fuel ratios due to cooler intake temps of water/methanol injection. This cause-and-effect scenario can create more horsepower, but may also damage an engine. Another problem we found was placing the nozzle before the blow-off valve, which causes an unwanted release of meth/water vapors at throttle let-off.

5. Charge Pipe

Placing the injection nozzle as far from the cylinders as possible on the intake charge pipe allows for the water/methanol mixture to be better absorbed into the intake air charge. This allows for greater distribution into to each cylinder, creating the coolest possible air charge.

6. Throttle Body

The most common location to place a nozzle is three to six inches from the throttle body. The nozzle should spray directly into the throttle body and should never be placed right before a tight-radius bend. Positioning a nozzle directly in front of an angled pipe can cause the liquid to adhere to the walls of the pipe before dribbling ineffectively into the intake manifold.

7. Intake manifold

Installing separate nozzles into each intake runner will deliver equal amounts of water/methanol to each cylinder. The only downside to installing the nozzles into the manifold is the additional labor and parts costs.