| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

When it comes to modifying small displacement engines - and believe us, we've been doing this a long time - our favorite weapon of choice is the modern marvel we call the turbocharger. Although the supercharger has always been a popular alternative, the turbo is still king when it comes to tuning cars, and it almost seems cooler and sexier for some reason. For example: we've seen generations of OE manufacturers integrating it into some of the most famous and beloved cars to ever hit the streets, like the Supra, MR2 or Silvia - and today, turbocharged factory engines continue to delight enthusiasts with the Evo X, STI and Hyundai's new Genesis coupe. But chances are that if you're reading this, you probably don't have a car that came turbocharged stock and you wouldn't be happy settling with anything stock. We all want more power, right? That means it's time to turbocharge that ish. But where do you start? With all the choices in selecting a turbo for your engine and driving style, figuring out which turbo is right can be a task unto its own. And that's why we're here; we're your shoulder to lean on - just look over your shoulders, honey!

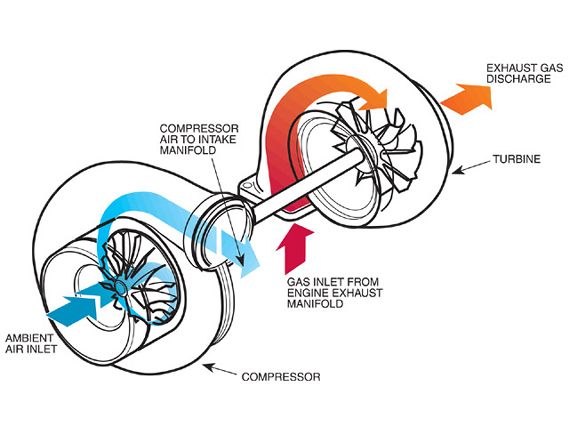

Before we dive into turbocharging, let's go over a few basics. In its simplest form, your engine is a huge pump and it's limited to the amount of air that it can breathe on its own. A turbocharger increases the amount of air that an engine can aspirate (inhale) by force-feeding it air. Hence the term "forced induction". Or as we like to say: more air and fuel equals more power. But like your girlfriend's taste in handbags, it's never that easy.

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

How Does Turbocharging Work?

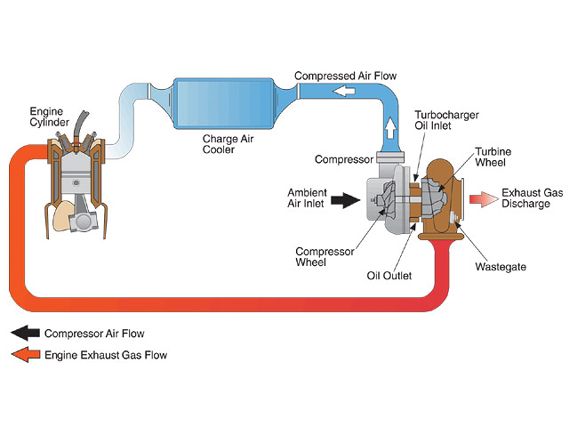

We know what you're thinking, "Thanks Captain Obvious; we know turbos make power," but how does that snail do it? The engine produces exhaust gases that flow through the turbo manifold, which are then funneled into the turbocharger's turbine inlet. The movement of these gases cause the turbine wheel to spool (spin) as they pass through on their way out your muffler. Since the turbine wheel is directly connected to the compressor wheel, as the turbine wheel spools faster, the compressor wheel will start to draw air in. At the same time it's drawing in, it's also pushing air out, similar to how a blow dryer operates. The volume of air increases to a point that it becomes compressed and charged (boost). But this air is usually heated as the turbocharger gets its energy from the spent exhaust gases. To cool down the air charge, the air passes through an intercooler to keep intake air temps in check (the cooler the temperature, the more efficient the motor becomes). This air then makes its way into the engine, forcing itself into the combustion chamber. This extra amount of air increases the volumetric efficiency of the engine, the byproduct of which is increased power. The spent gasses are then pushed out to reciprocate the process.

How Do I Choose the Right Turbo?

With so many choices in turbos out there to choose from, figuring out which turbo is right for you can be complicated. Lucky for you there are a few manufacturers who specialize in the art of turbocharging, like our special guests today: HKS, GReddy, Garrett and Turbonetics. Before you go out and spend your hard-earned cash, we recommend sitting down and building a game plan for your engine. What kind of power do you want to make and is it a realistic figure? Is your engine built or is it still stock? These are all important factors to think about because you have to consider how much power your engine can handle. Also, what kind of driving will you be doing? Is your project going to see any time on a track? Daily driver? This will help you figure out the target range of power that's right for you. Remember to also be honest with yourself at this stage; 500WHP isn't very realistic if you're drifting your S14 on the weekends or are going to sit in traffic on the daily with your Evo.

| A ball bearing turbine shaft

| A ball bearing turbine shaft

The basic rule of thumb with turbos is that smaller compressor wheels work well at lower pressures whereas a larger compressor wheel reaches peak efficiency at a higher level of boost pressure. This is due to the speed the shaft spins at. A slower shaft speed creates a denser air charge and improved efficiency in the turbo. In simpler terms, a car that isn't raced often will see greater benefit from a smaller sized turbo that responds better than a larger turbo that only performs well on the top end due to turbo lag (less efficient). The experts agree that once you figure out what kind of horsepower goal you want, you can use a compressor map to figure out which compressor will be the right size for the efficiency of your setup.

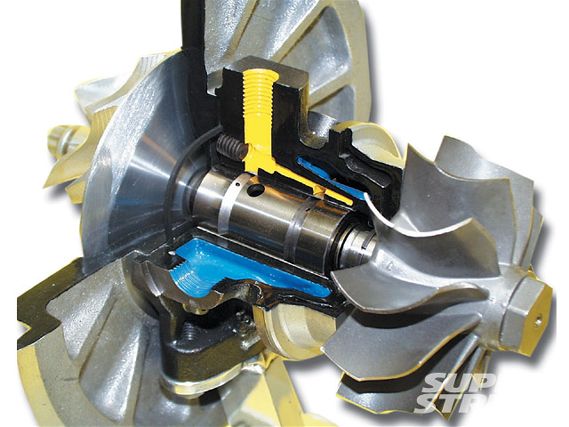

Ball Bearing Versus Standard Bearing Turbos

Just like your crank, you turbo rides on a thin film of oil sandwiched between a set of bearings, unlike your crank though, the turbine shaft sees upwards of 100,000 RPM. Therefore, any reduction in friction results in a huge increase in efficiency. The introduction of ball bearing center cartridges has given way to smaller frame turbos with capabilities of midsized standard bearing counter parts. Instead of a strip of metal, the ball bearing center cartridge design allows the shaft to rotate along tiny precision round bearings, similar to the ones found in skateboard wheels. This way, you can choose a large compressor wheel that can be matched to a disproportionately smaller turbine wheel.

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

The second area of interest, when it comes to bearings, is the thrust bearing. Under a high load environment, the exhaust pressure is pushing down on the turbine wheel. The shaft needs something to withstand this pressure. In a ball bearing application, the thrust load is virtually eliminated because of the tight clearance between the shaft and ball bearings. Ball bearing turbos are especially beneficial in an application that requires high response (ie: circuit racing, autocross, drifting and street) because the increase in peak effective boost is not as apparent as the spool up rate. This means that you can reach peak boost faster, increasing the amount of mid range power realized.

If you're thinking that it sounds too good to be true, you may be right. The biggest discerning factor between standard bearing and ball bearing turbos is cost. This is where the rule of "you want to play, then you got to pay" comes in. Expect to pay double (or more) for the price of a ball bearing turbo. On top of that, ball bearing cartridges are so expensive to service, you just don't. You either have to buy a new center assembly or buy a new turbo. As you can see, there's a give and take to everything.Whether you go with a standard type or a ball bearing turbo, maintenance is key having a long lasting turbo. Contrary to popular opinion, it is critical to run a filter on the turbo. At 100,000+RPM, any debris can wreak havoc on the wheels, whether it's on the turbine or compressor side. Rocks, dust, gasket material, pieces of a catalytic converter - they all mean bad news. Properly plumb your pipes and keep a filter on the turbo at all times. Check how much play the center shaft is getting (forwards to backwards, side to side and top to bottom); this will ensure that your turbo is working at its designed efficiency.

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

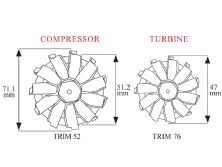

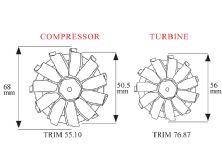

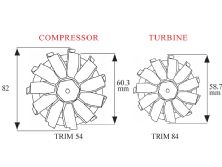

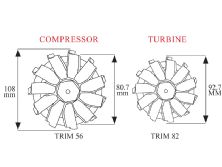

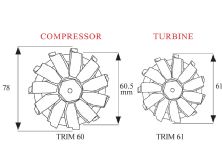

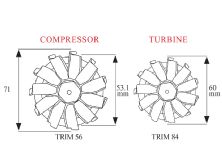

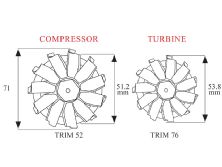

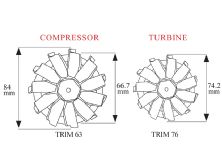

Trim Sizing and A/R

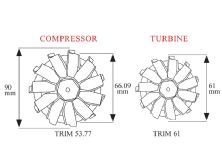

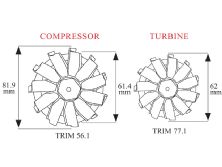

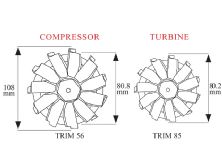

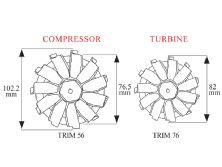

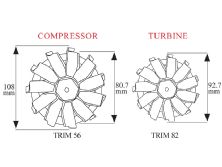

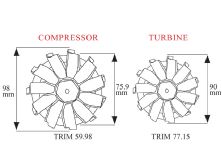

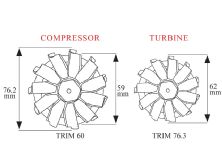

When you browse through the various turbo manufacturer's catalogs and websites, they usually list the trim size and A/R. According to Honeywell Garrett, trim is based upon the relationship between the inducer (the area where air/gas enters the turbo) and exducer (the area where air/gas exits the turbo). To be more precise, it's a ratio of area. Generally speaking, the larger the trim size (other things held constant), the more air a turbo can move.

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

| Turbocharge Understanding Guide - How a Turbo Works - Boost Basics

A/R is a geometric characteristic of the compressor or turbine housing. Although it can be applied to both compressor and turbine housings, usually we only concentrate on the A/R of the turbine side, as it can drastically change the spool rate. The A refers to the cross sectional area of the inlet divided by R, the radius from the turbo centerline to the center point of the area A. Since this area is where exhaust gas travels through to spool the turbo, a small area will increase the response and spool rate. At the same time, it will top out the efficiency limit of the turbo rather quickly. A larger A/R will take longer to spool (boost lag) but will be able to flow more air. In short, a small A/R has high response with limited power; a big A/R will result in slow response but with bigger power.

Turbo Breakdown

To help you in your quest of turbocharging your engine, we've gathered some of the most popular turbos together for a jam session. And whether it's streetable power or full-on drag racing you're seeking, we'll hope you'll find these suggestions as a launching point to your goal.

Selecting Your Turbocharger

For all you math geeks out there, HKS has provided us with a set of functions to mathematically determine which turbo size is best suited for your application and how much power you can expect out it. If you only excelled in home ec or PE, just follow the technical illustrations next to the corresponding pictures. Something to keep in mind: these figures do not take into account atmospheric conditions or the effects of intercooling.

1) Calculate the airflow for the engine in its naturally-aspirated form. Use the following formula for standard atmospheric pressure: CFM=(CID x RPM x 0.5 x Ev) / 1728. (CID: cubic inch displacement; EV: volumetric efficiency (0.80-0.90); CFM: air flow rate)

2) Knowing your desired boost level, calculate the airflow rate under boost by multiplying the pressure ratio by airflow rate (na - cfm). Calculate the pressure ratio: (14.7+Boost/14.7) - then calculate the air flow rate under boost by multiplying the pressure ratio by your air flow rate from step one: CFM x pressure ratio (for twin turbo applications divide this number by 2).

3) To covert CFM to lbs/min, use (CFM x 0.076 = lbs/min).

4) Use compressor maps to find the turbo best suited to the air flow rate and pressure ratios you have attained. You can get calculate a rough estimate on Engine horsepower using the following formulas:Lower value: 0.052 x CID x (psi boost + 14.7) = bhpHigher value: 0.077 x CID x (psi boost + 14.7) = bhp

Small Frame Turbos:

Characteristics: High response; good for dual purpose use, such as street and track (drift/circuit; street class drag racing); ideal for smaller 4-cylinder engines; est. 200-400hp

Mid-Frame Turbos:

Characteristics: Slight lag; suited for heavy track use (drift - Pro class; circuit - Modified class; drag - Unlimited class); est. 400-600hp

Large Frame Turbos:

Characteristics: Lots of lag but capable of pushing huge power; suited for larger displacement engines and high rpm power (think 2JZ-GTE or RB26DETT); perfect for drag racing, dyno bench racing or tractor pulling; est. 850+hp