| Ignition System Basics Part 1

| Ignition System Basics Part 1

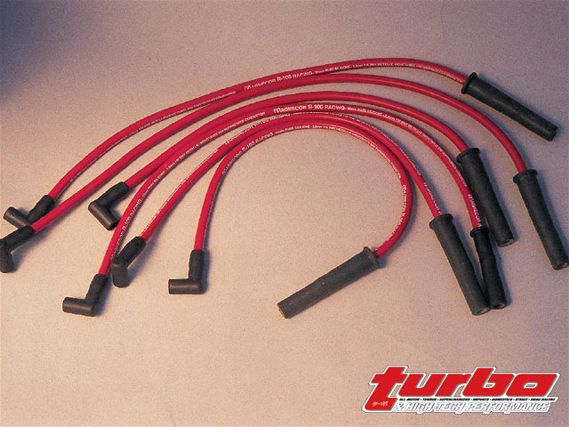

When it comes to ignition, plug wires are often the Rodney Dangerfields of the system. This is a misconception because while not the glamour boys of automotive electronics, spark plug wires play a key role in performance. As the demands of the ignition system increase the wires are asked to shoulder a more burdening load and failure can have catastrophic consequences.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

The stock set-up is adequate for mildly tuned combinations- an intake and exhaust for example. However, we have seen 125-horsepower Honda engines being pushed to well over 700, running boost levels up to 30 psi. As the performance of the engine is increased the ignition system must live up to higher and higher expectations. So when is the correct time to upgrade wires? Why is an aftermarket wire better than a stock wire? What is EMI? Will a plug wire "wear" like other components on a car?

| Ignition System Basics Part 1

| Ignition System Basics Part 1

When To Upgrade?When to upgrade is a tough question. It all depends on the performance of the OE set up, how many miles are on your existing wires and what you have done, or plan to do, to the engine in the future. As a basic rule anytime you increase the cylinder pressures within the engine or up the rev-limit of the engine an ignition upgrade should be considered.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

It is applications like forced induction and/or nitrous oxide that overwhelm the stock ignition system. Supercharging and turbocharging ups cylinder pressure through boost while a nitrous oxide system uses a chemical reaction to deliver the additional oxygen that results in higher cylinder pressures. Either way, lighting off the entire air/fuel charge efficiently is the key to realizing the optimum power output. Cylinder pressures can also be increased by upping the compression of a naturally-aspirated engine. Increasing the rev limit reduces the margin of error when it comes to the ignition system. Precise timing and sufficient energy are of prime importance as the time between firing cycles is shortened. The amount of boost, nitrous, compression and increase of rev limit will dictate when an ignition box and performance coil need to be added to the mix.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

Types Of WiresAs outlined earlier, OE wires are well-suited for their intended use. Most stock wires feature carbon conductors which can deteriorate over time. Their length of service time depends on the driving habits of the owner, the environment the car operates in, maintenance of other engine systems, degree of modification and quality of tuning found on the particular engine. Many OE wires do not react well to an upgraded ignition box and tend to deteriorate quickly when subjected to the high-energy output of such systems.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

In the performance wire arena there are three types of plug wires-solid wire conductor wires, spiral conductor wires, capacitor effect wires (capacitor wires feature either solid or spiral conductor construction) and "low resistance" wires. Spiral conductor wires are the standard, however solid conductor and capacitor effect wires have developed a following over the last couple of years. Capacitor discharge wires like HotWires from Nology are conventional wires with grounding straps and a built-in capacitor. Spiral conductor wires like those from Magnecor, Moroso and Vitek to name a few feature fine wire that is spun around a core. A low resistance wire, like the 8.5 Super Conductor from MSD that provides only 40 to 50 ohms of resistance per foot, features copper alloy that is spun around a core-a variable of a spiral wire. Solid core conductor wires work well on carbureted applications but may have a problem with electronic fuel injection cars because of poor EMI suppression. For the most part, aftermarket wires are up to the challenge when it comes to the intensity of aftermarket ignition systems, are built for high tolerances of heat and are able to adequate suppress EMI.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

What Is EMI?EMI stands for ElectroMagnetic Interference. EMI from plug wires can impact electronic systems ranging from onboard electronic equipment to stand-alone engine management systems, stock ECUs and sophisticated ignition systems. Much like Radio Frequency Interference affects radio reception, EMI can alter data moving between sensors and the computer or ECU which can cause erratic engine operation.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

Heat Vs. PerformancePlug wires and excessive heat often find themselves at odds with one another. The key word here is "excessive." With the exception of the one-piece, extreme high-temp aerospace-grade silicone rubber jackets used on Magnecor Race Wires which can withstand temperatures from 600 to 1000 degrees Fahrenheit, most wire insulation consists of multi-layer silicone/EPDM blends which are good from 250 to 400 degrees. The conditions that the consumer intends to put the wires in will dictate how much heat resistance is needed. Unfortunately, exhaust manifolds and turbo system piping can approach 1200 degrees and any wire positioned too close to these components are in trouble. Heat resistant sleeves, tape and ceramic and reflective-coated spark plug boots can be effective in some cases. Too often, however, they are used in conditions that require more invasive techniques such as rerouting the heat source, shielding the heat source from the wires or wrapping the heat source itself. Seven, eight, 8.5 and 10 mm wires refers to the thickness of the wire with the additional size usually made up of the wire's heat resistant materials. So with all the materials being equal the thicker the wire the better the insulation.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

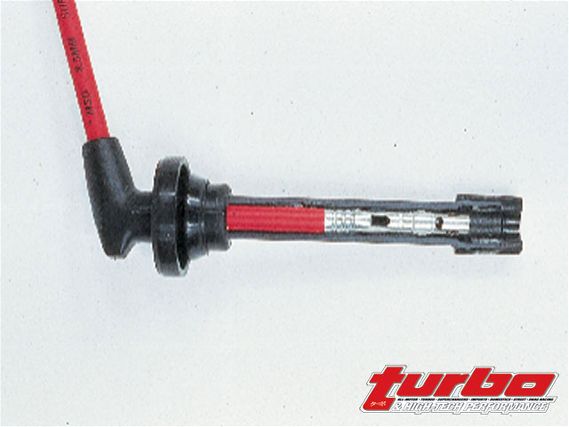

Water vs. PerformanceDrowning has become a concern of spark plug cable manufacturers. These water sports tragedies occur mainly in import applications. Deep well plug configurations found in designs from Honda, Nissan, Acura and Mitsubishi, to name a few, are prone to moisture accumulation around the spark plug connectors. When water settles in the well (after a wash, steam cleaning, driving in heavy rain or excessive moisture from dew) the wires arc through the water. This results in a sputtering unhappy engine and the destruction of the connector. In some cases the engine will not fire to life at all. So if you have just hosed down your engine and it won't start blow some air down the well. With higher-output ignition systems in operation the likelihood of arcing is greater. Manufacturers have stepped up and designed wires that address this situation but a keen eye should be kept on this problem as no wire is 100-percent impervious to water.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

Making PowerRarely will the addition of wires result in a boost in power. That is why they are not the "glamour boys" of the ignition. In some cases a smoother curve may be realized but generally output increases are hard to come by. The exception is when performance wires replace deteriorated stock offerings. Plug wires should be viewed as an insurance policy, insurance that future modifications will be able to realize their fullest potential because all the air and fuel in the engine will be efficiently and completely burned.

| Ignition System Basics Part 1

| Ignition System Basics Part 1

Installation & MaintenanceYou may ask, "what is there to do when it comes to installing and how do you maintain a wire?" The number of tuners who have seen seemingly serious engine problems that were the result of water soaked, poorly terminated and improperly fitted plug wires is astounding. The key is to purchase wires specifically designed for your engine and avoid "universal" application wires whenever possible. These universal wires present a number of pitfalls. They require the user to cut, strip, boot and terminate the wires by hand. Terminating the wire (attaching the metal piece that clamps to the plug) is a critical aspect of the wire's performance. This procedure requires a special crimping tool to be executed correctly and poorly crimped wires can quickly deteriorate. Also, depending on the frequency in which the owner changes or inspects the spark plugs, poorly crimped wires can be pulled apart at the terminal. Leaving the owner to figure out a way to extract the terminal and/or the plug MacGyver style.

The Purchasing DecisionThis is where the consumer can be hit with a heavy dose of hype. Most of the drama centers around the spiral conductor wire camp and the capacitor effect contingent. These two designs take a different tack when it comes to delivering the spark. The capacitor wire stores up its charge and releases it in a quick burst while the spiral conductor wires use a conventional long-duration spark. Typically a capacitor wire fires in four nanoseconds (billionths) at 7500 rpm while a spiral wire fires in four milliseconds (millionths) at 7500 rpm. At one point Turbo magazine was putting together a shootout style article but those involved put far too many conditions on the testing procedures and we were not even sure if we could produce viable data one way or another. So we declined to proceed. We do know that capacitor wires work better on some applications than others. The same can be said for some spiral wires. A new design that has added fuel to the fire is low-resistance wires. The theory behind low-resistance wires centers on the fact that if a current or charge loses power to the resistance in the cable then less resistance means more energy at the plugs. If you're a glutton for punishment you can surf the web and see the hype in person. We suggest contacting your local tuning shop, preferably one that carries both styles of wire, and get their opinion on which would be best for your particular vehicle. Remember to stay away from the Do-It-Yourself universal wire sets, look for good EMI suppression and address the heat resistance challenges of your combination.

In Part Two of this series we will outline stand-alone ignition systems and their impact on performance as well as showing you the latest in high-tech ignition-programmable boxes. Stay wired.