| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

The D-series recipe featured here may not be suited to everyone's taste. It is by no means the most powerful D-series ever built and it certainly isn't the easiest to put together. What it is, though, is a combination of parts assembled to make the most power possible within a specific set of rules. The motor was built a few years ago and to our knowledge is the only one of its kind. Its relevance to us is that while there is a good deal of machine work involved, the parts required are reasonably inexpensive. This could be the ultimate D-series sleeper motor.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

The engine was built to compete in NASA's Honda Challenge H1 hybrid class. In 2005, the rules were adjusted so that cars attempting to compete with a D-series engine could weigh 400 pounds less than the class-dominating, K20-powered cars. Additionally, while the K20 motors had to be basically stock, the D-series motors were allowed modest modifications. They were allowed to use any OEM Honda parts they wanted in the bottom end. Additionally, aftermarket parts were permitted in the valvetrain along with unlimited head preparation.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Everyone knew that the little motor could never match the power of its competitors. But, nobody was really sure if it could get close enough to take advantage of its lower minimum weight. The person who set off to find out was Bernardo Martinez of Redondo Beach, Calif. An accomplished H4 and ITA class racer, he already had a healthy collection of D16A6 motors ready for surgery. He laboriously tore them down and pieced them together with other parts until he found a combination that worked. Rival hybrid class competitors named his concoction the "inbred motor" but he always referred to it as the "Super D."

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

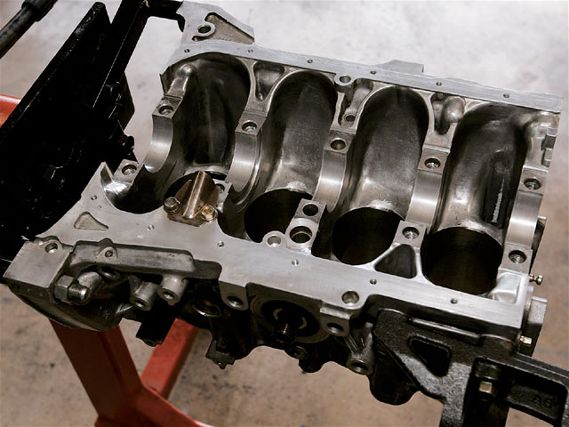

Super D Engine BuildThe foundation of any powerful race engine is the bottom end. This started with a well-used D16A6 aluminum block from an '88-91 CRX Si. The block was cleaned and then inspected for cracks and other potential defects. Next, the casting flash was removed and sharp edges were deburred with a die grinder. The block was then bored for the factory oversized pistons from a natural gas powered '04-05 Civic GX. These pistons are domed for higher compression but need to be notched for valve clearance. Their wristpins are located to match the stroke of a D17 crank. However, they are still slightly in the hole at top dead center. To maximize compression the block was decked by 60 thousandths of an inch.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

To increase engine stroke, a D17A7 crankshaft from an '04 Civic with a 94.4mm stroke replaced the D16A6 version, which only had a 90.0mm stroke. This bought the engine an extra 78cm3 of displacement. With the longer stroke, however, the rods interfered with the block and main bearing girdle. Both required the removal of some material for adequate clearance.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Upon assembly, D17 rods were fitted onto the crankshaft with high-strength ARP rod bolts. The D17 crank required the use of a D17 oil pump, which in turn, was only compatible with the D17 oil pan. A D17 oil pickup and main cap seal were also needed to make things fit. The final fitment issues with the D17 crank were with its larger snout diameter. The timing belt pulley from the D17 needed to be used but first the crank trigger wheel needed to be machined off. Lastly, the D16A6 crank pulley had to be bored and re-keyed to match the D17 crank's snout.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

The D17 oil pan sits lower in the car than the D16A6 unit, which put it closer to harm's way in relation to ground clearance. To be safe, Bernardo cut out part of the oil pan at the sump to allow more space for the oil to flow around the pickup. Occasionally, a smashed oil pan blocks the flow of oil to the pickup causing a loss of oil pressure to the engine. Having no oil pressure will eventually destroy the engine-not good.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

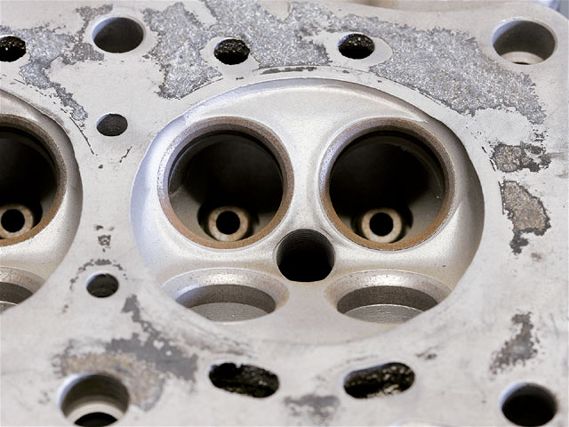

Experienced engine builders know that real horsepower lurks in the cylinder head. To start, material was added to the combustion chambers and then reshaped to improve combustion efficiency and increase compression. As a result, the motor's compression ratio ended up at 13.2:1, which is much higher than the stock D16A6's 9.1:1.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Next, of course, was to reshape and massage the intake and exhaust ports. Bernardo, having little experience with these modifications, enlisted the help of Joe Alaniz of Alaniz Cylinder Head Technologies to give him a crash course on head porting. Working on a thrashed donor D16A6 head, Bernardo apprenticed in the art of cylinder head porting. With Joe's help, he was able to improve the airflow through the head by approximately 35 percent.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Once the head modifications were complete, Joe cut new higher-flow valve seats into the head; 1mm oversized PEP stainless intake valves were then back cut down to the stock diameter. Just about the only H1 rule for cylinder head preparation is that stock sized valves must be used. Still, this extra step improved flow and further increased the compression.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

A Gude Gorilla Jr. camshaft was sourced to increase mid-range and top end power. The aggressive cam uses 0.409 inches of lift with 261 degrees duration for the intake and 0.404 inches of lift and 237 degrees of duration for the exhaust. It required upgraded Gude valve springs and titanium retainers to keep the valves from floating at high rpm. Once the engine was completely assembled, a Clutch Specialties lightened flywheel and clutch were used to help build revs quicker.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

An AEM adjustable fuel pressure regulator and fuel rail were used to dial-in the proper air/fuel ratio. In addition, an AEM cold-air intake and alternator underdrive pulley were installed. Finally, the mastermind in charge of extracting maximum performance from the Super-D was an ever-versatile AEM EMS unit.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Tuning was done using a Dynapack hub-mounted dynamometer at Shawn Church's facility. H1 rules require that an OEM intake manifold be used. After going through several intake and exhaust manifold combinations, the best results were found with a D16Y8 intake manifold from a '98 Honda Civic EX matched to a Bisimoto header and custom exhaust.

The ResultsShawn and Bernardo spent a good deal of time fine-tuning the EMS along with the cam and ignition timing. Their best run produced a horsepower reading of 171.1 at 7600 rpm. But, this was dialed back to 165 at 6900 for a much fatter torque curve peaking at 135.2 lb-ft at 5400 rpm.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

The true test of the motor would be out on the track. Bernardo and his Super-D powered CRX qualified consistently well. But, he would lose positions on the series' standing starts every time. The motor just didn't have the off-the-line grunt that the higher displacement iVTEC-equipped competition had. Once up to speed however, it could hold its own.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Where it really shined was toward the middle and end of the races. The heavier, more powerful cars were much harder on their tires causing them to fall off over time. The CRX with its lighter weight, especially over the nose, could maintain its pace and would routinely make late race charges back through the field. All of the hard work that went into developing the Super-D finally paid off at Buttonwillow Raceway where Bernardo started on pole, lost a few positions on the start, then pulled off a late race pass for the win. Shortly after the race, Bernardo was signed to drive Hasport's K24-powered Integra. Sadly the Super-D has been mothballed since.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

While the race version of this motor proved to be successful, there is perhaps even greater potential for this setup as a street motor. The full race cam, head prep, and overbore aren't really necessary for a mild build. Without them, all you'd really need is a used GX motor to pull the guts out of and a good machine shop to go to. You could have a nice little stroker motor and nobody would even know it. Long live the Super D!

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

The Super D lives!This just in. The Super D has recently been shipped out to the East Coast. Honda Challenge H4 National Champion, Colin Botha is installing the motor in his CRX. He'll be attempting to take on the H1 field at the NASA National Champion-ships at Mid Ohio in September. We'll be there to witness its return firsthand.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Editor's Note:I Don't Get It.After reading this story I was left with one big question. Why? Why go through all this trouble of modifying the D16A6 when the D17 crank and pistons obviously fit in the D17 block from the factory?

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

The next question of course was, why not just swap the D16A6 head onto the D17 shortblock? This was not feasible because the head bolt pattern is not the same and the oil galley holes don't line up. As if that wasn't enough, there were other compatibility issues such as the D17 block not being interchangeable with other D-series transmissions, and requiring custom motor mounts to fit in the CRX chassis. In the end, the process of stuffing the D17 internals into the D16A6 made the most sense.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Another interesting tip from Bernardo was regarding sourcing the GX internals. Natural gas powered Civics are already rare and finding them in the junkyard is nearly impossible. He recommended pulling the D17 block out of an EX or DX Civic then ordering new GX pistons and rings from a dealer.

Bernardo's explanation was that the D17's head was incapable of producing the power that the D16A6's head could. At the time there were no aftermarket parts available for the valvetrain. Intake manifold compatibility was also an issue. The D17's head uses a totally different port design from the D16. This left the D17's head stuck with the plastic D17 manifold that could not flow like the D16Y8 manifold could.

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

| Super D - Wrenchin - How Do You Do That Thing You Do? - D-Series Tech

Hope that clears things up. -AH