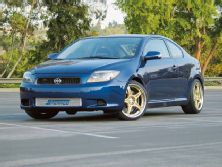

"Time is of the essence." We can't tell you how many times we've repeated that phrase in the past month while building a Scion tC for the SEMA International Auto Salon.

As mentioned in last month's "Tech Scene," Turbo worked alongside Performance Dealer Options (PDO) of Irwindale, Calif., to modify the first Scion tC in time for its debut at the IAS show. The only problem: we were given three weeks to complete the transformation.

We took delivery of the tC on March 10, exactly 21 days before roll-in for the IAS show on April 1. The only request Scion had was for it to be painted the same color as the Scion xB and xA we previously modified. As you know, finding a body shop to paint a vehicle inside and out in a short period of time is nearly impossible. Having the shop perform the job in a week so we'd have two weeks to finish the Scion is like asking for a miracle.

Not only did we plan on painting the vehicle, we also wanted to turbocharge it, lower it, add a big brake system, upgrade the interior, add an exhaust system, and install gauges as well as other accents. All of this had to be done in three weeks. And did we mention the tC is a new platform and no companies make parts for the vehicle yet? Unlike the xB and xA, there are no Japanese versions to scavenge J-spec tuning parts.

Day 1: March 11

We trek to TEE'S USA for our Bride XAX II seats and to purchase the material we need to restitch the rear seats in the same material as the front seats. But the material for the rear seats won't be available until March 26, five days before roll-in. Then, at A'PEXi USA, Jensen Oda and Lanny Higa help us fabricate a set of seat brackets for the Scion. We finish the bracket at 8:00 p.m.

Day 2: March 12

A new day with more work than humanly possible is on the horizon. At the Toyota dealership we purchase an exhaust manifold gasket so we can have a stainless-steel flange made for the turbo system we plan to build.

Fortunately, the gasket is in stock. We go to the local metal yard to pick up stainless-steel flat stock for the flange, then drop off the flange at Sierra Laser Center to have the flange cut. The flange will be done in a week. Then we pick up from Blitz in City of Industry, Calif. the electronics that will monitor the turbo system.

Day 3: March 13

We wake up late--hey, it's the weekend. We begin installing the gauges in the tC. Mike from Wilwood comes by to measure the Scion front and rear brake systems so he can start constructing the system for the tC. We start to fabricate a gauge panel for the Blitz SBC I-D boost controller and Power Meter in the factory cup holder slot. Note to self: buy a compass next time.

Day 4: March 14

We perform wheel fitments on the tC since the wheels will also be custom pieces from Japan. After several hours of removing the suspension to inspect for wheel travel, we're confident of our wheel fitment selection. We then e-mail Speed Star Wheel in Japan with the fitment sizes. "P.S. Time is of the essence" is typed as an afterthought. The wheels must be done before IAS to give us ample time to mount, balance and install them.

Day 5: March 15

The car is supposed to be dropped off at the body shop, but Steve Hatanaka from Toyota calls us saying that one of the press vehicles has a set of Tein coil-overs on it that's ours if we want. After several hours of wrenching at Toyota, the Tein system is installed on our tC and we drop it off at Duran's Body Shop. We tell them, "Time is of the essence."

Day 6-12: March 16-22

The crew at Duran performs the miracle we didn't think was possible. On Friday, March 19, the car is painted and they're in the process of putting it back together. They finish the car on Sunday, March 22, and it looks awesome.

Day 13-17: March 23-27

Technically, we drop off the car Monday night, but Turbonetics isn't able to work on the car until Tuesday morning. Jaime from Turbonetics performs the second miracle. He builds a work of art, a long-runner stainless-steel manifold utilizing the flange we had cut and a Burns collector. The front-mount Spearco intercooler dominates the front end, while a ball-bearing Turbonetics T4/T3 turbocharger provides the boost. The system is connected via aluminum I/C piping. We wonder how Jaime got everything to fit in the compartment between the radiator and head. He's a miracle worker.

Day 18: March 28

After several heated discussions about whether to remove the turbo system and have the piping and manifold polished before the show, we decide to go for it. The show is four days away. We don't even know if the polishers can have it done in time, but we take the risk. Jaime at Turbonetics tells us it's a jigsaw puzzle and it can only be removed one way. Fortunately, we're able to remove the system easily.

Day 19: March 29

The manifold and piping are left at Speedway Metal Finishing. They guarantee us it'll be done by Wednesday, the day before the show. Then we go to Lot USA to get the Bride material that was held up at Customs. The material and rear seats, front and rear door panels and the center armrest are taken to Apollo Upholstery. The techs there inform us that all the pieces will be done late by Wednesday, too.

Day 20: March 30

We have nothing to do to the tC, but there's another project vehicle that blew up that needs to make it to the IAS show. We're able to locate an engine for the vehicle and have it swapped in the next day.

Day 21: March 31

We're at the polishers the first thing in the morning but the pieces aren't done, so we wait a couple of hours. With pieces in hand, we go back to our shop to figure out how this jigsaw puzzle goes back together. Twenty pairs of latex gloves later, the system is installed (we wear gloves because oil from your fingers can stain the manifold).

Then we install the Wilwood front brake system. Unfortunately, the wheels are not here from Japan yet. The interior is completed by 6 p.m. Then we spend the next couple of hours installing the front and rear panels as well as the rear seats and arm rest.

Day 22: April 1

Roll-In: The wheels arrive via UPS in the morning. At Sprewell Racing, the tires are mounted and the rolling stock is secured on the vehicle. Recent rains have the Scion caked in road grime, so it gets a bath. The neighbor makes some smart remarks about us washing a car in rainy weather. We get to IAS at 6 p.m. and the car rolls in by 7 p.m., but we still have to attach the vinyl stickers representing all the people and companies that helped with the project. We finish putting on the stickers and perform a quick detail by 10 p.m.

April 4: Last Day Of IAS

The icing on the cake isn't only that Scion is extremely happy with the vehicle we delivered, but that the tC wins second place in the Sport Import Class car show. That's pretty amazing, considering we only had 21 days to turn the tC from a dud to stud. There's plenty more left in store, including a body kit, bigger wheels, a rear brake kit, dyno tuning and miscellaneous interior upgrades. Stay tuned as we show you the true meaning of tC--turbo Charged.