Rotary Evolution: Part 1

Most Japanese performance car enthusiasts are familiar with the 13B twin-rotor engine Mazda equipped the RX-7 and RX-8 with. But unless you've owned and modified an RX of some type, chances are you have only a basic understanding of how this unique type of combustion engine differs from a more traditional piston engine. If the name Dr. Felix Wankel means nothing to you, then here's your chance to learn everything you ever wanted to know (and more) about rotary engines. Spend a few minutes reading this story and you may just find yourself falling in love with this strangely ingenious engine design and looking at rotary-powered Mazdas like the RX-7 and RX-8 in a whole new light.

|

Rotary Engine Evolution - Tech

|

Rotary Engine Evolution - Tech

A (Not So) Brief History The history of the rotary engine is a strange and wonderful tale that dates back as far as 1588 when Ramelli invented the first rotary-piston-type water pump. Almost 200 years later James Watt, a Scottish inventor and mechanical engineer whose pioneering work with steam engines helped drive the Industrial Revolution, invented the first rotary steam engine in 1769. So although we motorheads (and rotorheads) tend to give Dr. Felix Wankel (1902-88) sole credit as the inventor of the rotary engine, the truth is that rotary engine design goes back much further than this 20th century German engineer.

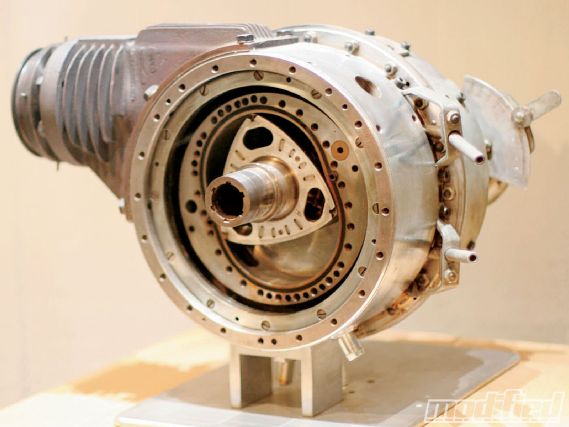

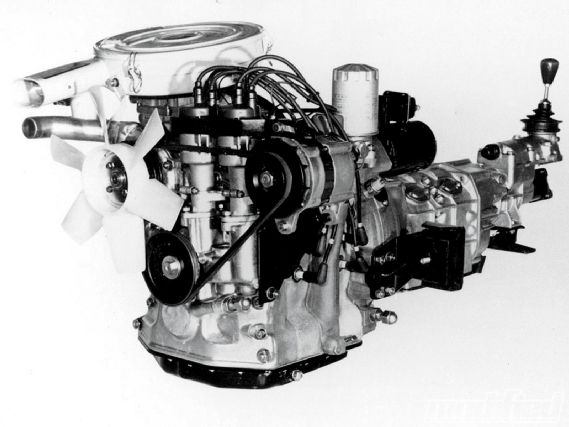

Still, Wankel's story is a fascinating one. His obsession with the idea of building a rotary engine began in 1919 when, at the ripe old age of 17, he had a strangely prophetic dream that he invented an engine that was half-turbine, half-reciprocating in design. With no formal training (he was granted an honorary doctorate later in life), Wankel set up his own research lab at the age of 22 and began pursuing his dream. Fast-forward to World War II when, as a member of the Nazi party, Wankel continued his work with the support of the German Aviation Ministry and private funding from the corporate sector, both of which believed that the development of a rotary engine would give the nation and its industries an advantage over its enemies. After the war Wankel was eventually able to re-establish himself (having been imprisoned for a short time by the allies, his lab closed and research confiscated), starting the Technical Institute of Engineering Study, where he continued his rotary engine R&D. Shortly after, in 1951, Wankel partnered with motorcycle and car manufacturer NSU and just six years later he and NSU completed a prototype rotary engine called the DKM. This first working prototype used a rotating cocoon-shaped rotor housing and a triangular rotor, but it was the KKM with its static rotor housing - completed a year later in 1958 - that's considered the true forefather of the modern rotary engine.

|

The first working rotary engine prototype, the type DKM, was designed by Dr. Wankel and built by automaker NSU.

|

The first working rotary engine prototype, the type DKM, was designed by Dr. Wankel and built by automaker NSU.

It wasn't until 1963 that the first rotary-powered car hit the streets as a '64 model year NSU Wankel-Spider. Then, in 1967, NSU released the Ro-80 sedan with a two-rotor 113hp Wankel engine and earned Car of the Year accolades in the European press. But because of the extremely costly development of the rotary engine and damage done to the brand's reputation by rotor apex seal reliability problems, NSU was taken over by the Volkswagen Group in 1969 (which merged NSU with Auto Union to form Audi) and the use of Wankel rotary engines was phased out.

But before NSU's merger with Auto Union, as joint patent-holders Dr. Wankel and NSU sold licenses to other automakers to develop their own versions of the rotary engine. Most major automakers bought a license during the '60s and began rotary-engine development programs of their own (the smooth and quiet operation and fewer moving parts of a rotary engine having strong appeal), but as you know it was the relatively small Japanese car company by the name of Mazda that eventually emerged as the only automaker able to mass-produce reliable and cost-effective versions of Wankel's design.

|

Rotary Engine Evolution - Tech

|

Rotary Engine Evolution - Tech

Mazda's journey into the world of rotary engines began in 1961 when then president Tsuneji Matsuda personally negotiated a licensing agreement with NSU. As part of this agreement, Mazda obtained a prototype of an NSU-built single-rotor engine and first learned of the "chatter mark" problem. These chatter marks, something Mazda's engineers nicknamed "nail marks of the Devil," presented themselves as wavy traces of abnormal wear on the rotor housing, causing the seals and the housing itself to significantly deteriorate. This was a major roadblock to the practical and widespread use of rotary engines and it was Mazda's own engineers - having formed its RE (Rotary Engine) Research Department - that eventually solved the problem.

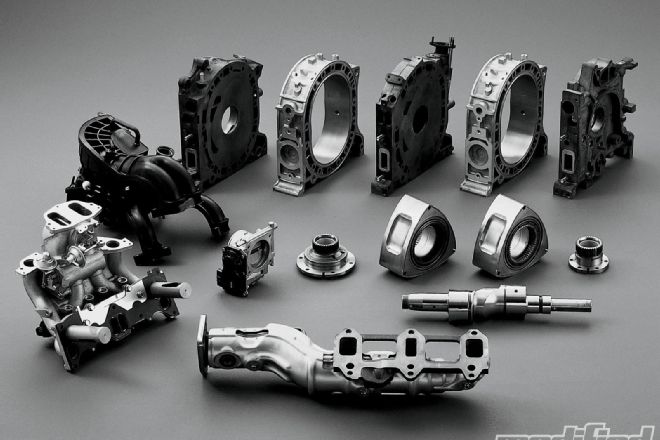

Recognizing the limitations (and in particular the lack of low-end torque) of a single-rotor engine design, Mazda began investigating two-rotor, three-rotor and four-rotor designs while working on solving the apex seal vibration issue causing the chatter marks and the oil consumption problem caused by a leaky oil seal. Just three years after signing the licensing agreement with Wankel/NSU, their second two-rotor test engine, called the Type 3820 (2 x 491cc), was built. This engine evolved into the 10A mass-production two-rotor engine featured in the now famous and highly collectible '67 Mazda Cosmo Sport. Pumping out 110 hp, the 10A two-rotor engine was equipped with newly developed, high-strength, carbon-based apex seals that showed only slight wear and none of the dreaded chatter marks after 100,000 km of testing. It would seem that Mazda had solved the dreaded "nail marks of the Devil" and had also cured the oil consumption issue by developing a unique oil seal in conjunction with the Nippon Piston Ring Co. and Nippon Oil Seal Co.

|

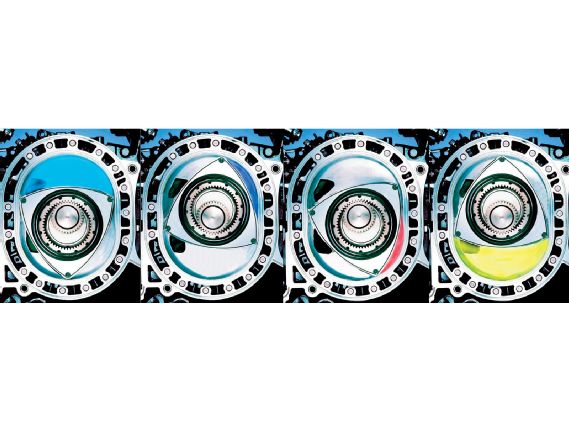

The four stages of combustion, starting with the intake charge entering the rotary housing via the intake port (light blue), the intake charge being compressed (dark blue), the compressed air/fuel mixture igniting with the aid of a spark plug (red) and the byproducts of combustion exiting the exhaust port (yellow).

|

The four stages of combustion, starting with the intake charge entering the rotary housing via the intake port (light blue), the intake charge being compressed (dark blue), the compressed air/fuel mixture igniting with the aid of a spark plug (red) and the byproducts of combustion exiting the exhaust port (yellow).

How the Rotary Engine Works So that's how the Wankel rotary engine was born and eventually became synonymous with Mazda. But how exactly does a rotary engine work? There are some excellent videos on the Internet that illustrate how this unique piece of engineering comes together, but here's a quick overview to get you started.

At the heart of a rotary engine is a trochoid-shaped rotor (looks a bit like a bloated triangle) that spins on an eccentric shaft within an oblong or cocoon-shaped rotor housing. This design results in three spaces between the rotor and housing wall, creating the required chambers in which the four parts of the combustion process (intake, compression, ignition and exhaust) take place.

Part of the genius of the Wankel rotary design is the way the eccentric shaft interfaces with the rotor. There's an inner-toothed gear ring fixed on the inside of the rotor and an outer-toothed gear fixed on the eccentric shaft, with the turning speed between the rotor and shaft being 1:3. In other words, the rotor rotates once for every three revolutions of the eccentric output shaft.

|

Rotary Engine Evolution - Tech

|

Rotary Engine Evolution - Tech

What this means is that with the engine running at 9000 rpm, the rotor itself is only spinning at 3000 rpm. This allows the relatively small displacement of, say, the 13B two-rotor engine featured in FC and FD RX-7 (654cc per rotor for a total displacement of 1.3 liters) to produce very impressive peak horsepower figures. It's this rpm overdrive or multiplier effect from the way the rotor interfaces with the eccentric shaft that creates such tremendous volumetric efficiency from these very compact engines.

The output shaft multiplier effect is also part of what makes rotary engines feel so smooth and quiet compared to a traditional piston engine. During a single combustion cycle the eccentric output shaft of a rotary engine spins three times and the rotor itself completes just a single revolution of the rotor housing. Meanwhile, in a traditional piston engine the crankshaft (output shaft) makes two full revolutions to complete a single combustion cycle and each piston travels up and down its cylinder three times. The very high piston speeds that result from this, along with all the additional moving parts in the cylinder head(s), means there's a lot more noise and vibration produced by a piston engine as compared to a rotary engine.

The simplicity and efficiency of the rotary engine design is impossible to deny. It's an elegant and intriguing piece of engineering, and although Mazda has succeeded admirably in producing reliable and powerful rotary engines for the last 43 years, as modifiers and tuners the question becomes what can be done to improve upon the reliability and power of these amazing little engines? For that you'll have to tune in to Part 2 of this story in next month's issue, where Jim Mederer of Racing Beat chimes in with some very useful insights based on his over 30 years of rotary tuning experience.

|

The larger-diameter gear inside the rotor provides a three-times multiplier effect to the speed at which the eccentric output shaft spins.

|

The larger-diameter gear inside the rotor provides a three-times multiplier effect to the speed at which the eccentric output shaft spins.

EARLY ROTARY ENGINE TIMELINE 1958 Dr. Wankel and NSU complete the type KKM that would become the basis of the currentrotary engine. 1961 Mazda signs agreement with Wankel and NSU for use of their rotary enginetechnology. 1963 Mazda forms the RE (Rotary Engine) Research Department to solve the chatter marksand oil leak issues that plagued early rotary prototypes. 1967 Mazda announced the world's first commercial two-rotor unit, the type 10A. Itdeveloped 110 PS and stars in the cosmo Sport (S110). 1972 Mazda equips the Luce AP with the first of its 12A low-emissions rotary engines. 1982 Mazda builds the first turbocharged rotary for the Cosmo RE Turbo. This 12A enginewas also the first fuel injected rotary engine.