| Project EVO: Part 3

| Project EVO: Part 3

When we last left Project EVO, we were frustrated because the poor quality of California's 91-octane gas was giving Project EVO fits and making us look like idiots. Despite our best efforts and using some of the best tuning parts available we were unable to see power gains other tuners have achieved with similar parts. Armed with an impressive array of bolt-on performance parts we were only able to eke out an honest 30-hp gain from project EVO, boosting its power from a stock 232 whp to 262 whp after a bit of cam timing on the dyno.

Although the power gains are seen across the board with no loss anywhere in the powerband we are deeply disappointed. Other EVO tuners, using similar bolt-ons, have managed to push output to more than 300 whp on pump gas in other parts of the country where 93- and 94-octane gas is readily available.

| Project EVO: Part 3

| Project EVO: Part 3

The EVO's active engine control computer thwarted our attempts to make power by retarding the timing, lowering the boost pressure and fattening up the air/fuel mixture if even the tiniest hint of detonation presented itself. The ECU's fluctuations made up to 10- to 15-hp variations between runs. This lack of repeatability made it difficult to determine the effectiveness of some of the mods.

The underdrive pulley gains were lost in the data noise and our exhaust system made 7 to 30 hp, depending on which run was chosen. We conservatively chose middle of the road power gains but some of the high output runs we discarded showed the possible potential of the mod if you took out the effects of the poor quality fuel.

| Project EVO: Part 3

| Project EVO: Part 3

What we needed to do is to take charge of Project EVO's engine control system and tune it ourselves. Our goal was to see how much power we could safely make on California's 91-octane pee-like fuel through the catalytic converter. We also wanted reliability for time attack type events on road courses.

Road racing is very demanding. The engine may be at full throttle for a minute or more and will remain at full throttle and under high loads for extended periods of time, lap after lap, for as long as 40 minutes a session. This is way more taxing than a 10-13-second blast down the quarter mile. Road racing, not drag racing, is the ultimate test of tuning and durability. We want a car that can run like this, not a sprinter drag machine or a dyno queen tuned to the limit on the dyno, only to blow up during a long pull around California Speedway's oval.

| Project EVO: Part 3

| Project EVO: Part 3

For assistance, we turned to one of the EVO tuning masters to run on California gas, Shiv Pathak of Vishnu Performance Systems. Shiv has a road racing background and plenty of experience tuning a car so it can live while being pummeled for long periods of time. Shiv's cars have a reputation for being quite reliable among California's EVO-armed hot lappers.

Recently, a Vishnu-built EVO putting out more than 500 whp through a stock bottom end won its class in the grueling Cannonball One Lap of America race. During One Lap, the cars must be driven literally for one lap around America unsupported during the course of the event. There are daily stops for time trials and special stages, like skidpad and drag racing. The Vishnu car was pounded at 25 to 30 psi on road courses and dragstrips while being driven for extremely long distances around the clock at high speeds for thousands of miles. The little EVO won the sedan class and placed fifth overall, beating many exotic, highly modified and expensive cars. As a testament to Vishnu's tuning skill, the EVO still ran perfectly after the event.

| Project EVO: Part 3

| Project EVO: Part 3

When developing a tuning program, Shiv is as conservative as he needs to be. Each programming step must take a full load dyno blast for more than a minute. The car is run at full throttle for 20 seconds at each 1000-rpm increment without registering any significant knock sensor activity. The engine must not register a significant loss of power on subsequent runs, not just during the dyno pass! That tuning pass/fail methodology is a testament to the reliability of Vishnu's tuning.

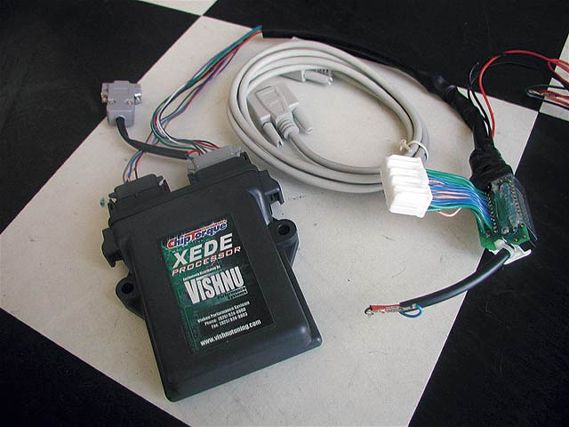

For engine control, Shiv first flashes the factory ECU with a performance base program using the Xflash tuning system. The Xflash is an ECU reprogramming system for the EVO that is capable of revising all performance-related engine control parameters. The high- and low-octane fuel tables, high- and low-octane ignition timing tables, adaptable knock control logic, injector scaling, boost limits, rev limits and speed limits can all be modified depending on the application.

| Project EVO: Part 3

| Project EVO: Part 3

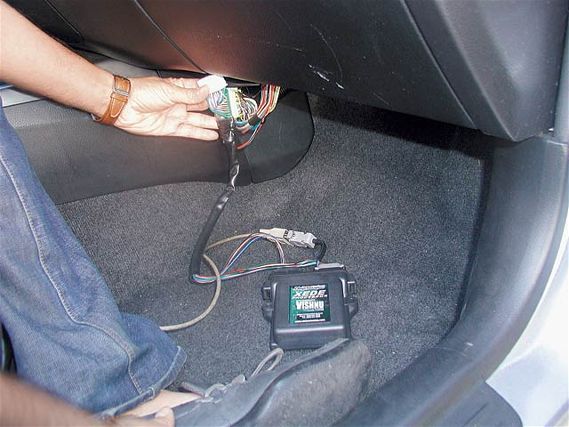

For our application, we needed something more than just an ECU reflash. We needed something that would allow us to have multiple maps for race fuel and water injection operation. To allow multimap capability, Shiv installed his user-programmable XEDE piggyback ECU to work in conjunction with our Xflashed stock ECU (which itself was only remapped for higher boost and rev limits). The XEDE is a sophisticated piggyback ECU capable of altering every critical signal input and output of the factory ECU. This way it avoids the typical pitfalls of piggyback ECUs, fighting the factory self-learning control.

The XEDE has some drawbacks though. It cannot raise the rev limit, speed limit or boost cuts (that's where the XFlash comes in). Like a typical piggyback, it must alter the MAF sensor's signal to trim for larger injectors. This used to be a significant disadvantage because altering the MAF signal can also put the engine in the wrong cell of the spark table. This, fortunately, is easily accounted for due to Vishnu's knowledge of the factory ECU tables.

| Project EVO: Part 3

| Project EVO: Part 3

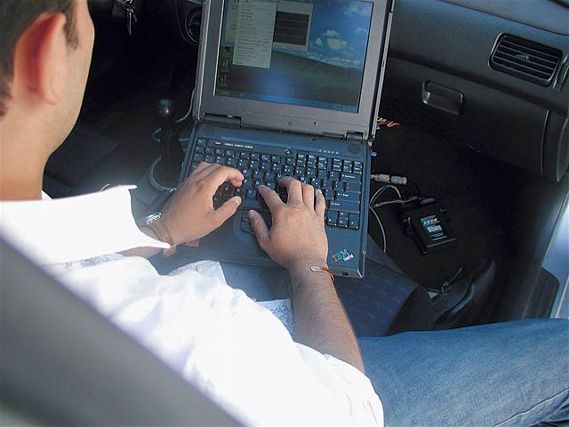

We drove Project EVO to Vishnu's Northern California headquarters for a tuning session with hopes of exorcising our car's low-octane demons for good. At Vishnu, Shiv strapped Project EVO to the rollers of his Dyno Dynamics AWD dyno and went to work by first downloading an Xflash to the factory ECU. Next, Shiv installed the XEDE and revised the factory fuel and timing maps. Finally, he experimented with different cam timing scenarios only to determine that our prior settings were close to optimal for the Tomei camshafts.

About then we ran into our first problem. After many pulls our air/fuel ratio started to get inconsistent, fluctuating between normal and lean. Turns out our fuel pump was overheating and losing efficiency. According to Shiv this is a common problem when the stock fuel pump is being pushed to its limit. The fuel pump was quickly swapped out for Vishnu's 255 liter per hour high-capacity pump and we were back in business.

| Project EVO: Part 3

| Project EVO: Part 3

With the stock ECU tune, our boost pressure would vary from run to run, from as high as 19 psi to as low as 15 psi depending if detonation was detected. Shiv set our boost at 20 psi and raised the rev limit to 8000 rpm, removing the speed cut. He also modified the fuel and spark maps and limited the amount of knock retard.

After perfecting the 91-octane-specific XEDE map, Shiv wired the XEDE to control our Aquamist water injection. He then developed a specific water-friendly map, advancing the timing and leaning the mixture slightly. Since we plan on using the water mostly as a thermal control when running the car at the track on hot days, Shiv was conservative and did not push the limits of the water's anti-detonation capabilities.

Driving Project EVO on the long trip home to Southern California, we were amazed at the difference in power and driveability. The throttle response was greatly improved and the turbo spooled faster. We are also getting slightly better fuel economy. We were eager to return to XS Engineering and check the power output compared to our last dyno sessions. The car felt powerful and we were eager to see just how much more powerful it was.

| Project EVO: Part 3

| Project EVO: Part 3

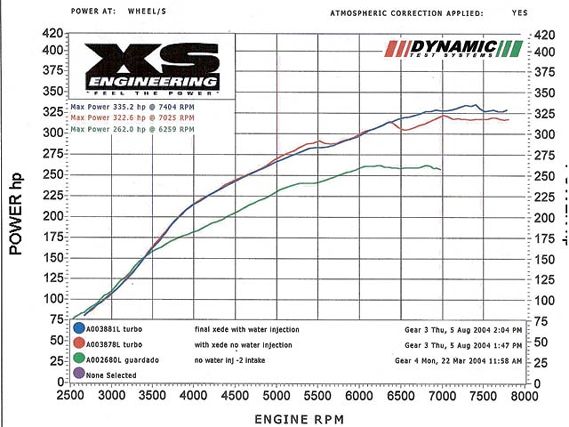

We booked time at XS and redyno'd our car against our prior runs. We were amazed at the difference. On 91-octane pee water, Project EVO belted out 323 whp at 7025 rpm, an unbelievable 61-hp gain from our previous poor showing. We knew that the tuning had made a big difference but we were amazed to see it here right in our face. Now our car is where is should be given the bolt-ons installed.

That said, we turned on our Aquamist water injection system to see its effect on power. Remember, we had tuned the injector system very conservatively, using it mostly for reliability and thermal control instead of a power adder. With the Aquamist water injection system turned on, our 4G63 belted out 335 hp at 7404 rpm.

We were stoked; we had gotten more power with an even greater margin of safety. This power level is pretty good considering the EVO's 4WD system soaks up more power than your typical FF or FR powertrain.

For instance you would be looking at least 360 whp on a 2WD dynojet, an awesome amount of power considering we are running 91-octane, a clean-air catalytic converter, a stock turbo and have total reliability.

In the next installment of Project EVO, we will add a race-only catless downpipe and tune the ECU for race gas and maximum safe power, sticking to the bolt on theme.