Since we last left off in our build, we upgraded our S2000 with a set of Tein Mono Flex coilovers, Suspension Techniques sway bars, Buddy Club bucket seats, a Kaaz 1.5-way limited-slip differential, Wilwood big-brake kit, and Spec clutch. After months of planning and weeks of installing parts, we have finally arrived near completion. At this point, you may be thinking that this build is overkill for the average street car. We would resoundingly agree, but excessive planning and building is what is going to take us to our promised land of sub-two-minute lap times at Buttonwillow Raceway. With much of our build geared towards suspension upgrades and aerodynamics to improve the vehicle’s handing, we haven’t forgotten about adding some much needed grunt to our beloved F22C engine. Follow along our buildup process as we upgrade our suspension and install Design Craft Fabrication’s infamous iVTEC system.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

The S2000’s highly rigid body and X-frame chassis are major contributors to its excellent handling characteristics. What’s the S2000’s X-frame chassis, you ask? Simply stated, the front and rear portions of the chassis frame and the side sills tie into diagonal braces (X-braces) at the rear of the cockpit and at the front cowl. These X-members connect the front and rear suspension subframes to resist chassis twist, and also provide a strength that’s been proven by Honda to be greater than what many closed-top sports cars achieve.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Chaser Hardtop

We replaced the OEM soft top with an aftermarket Chaser Aerodynamics hardtop. With optional OEM hardtops selling for $2,000 the cost would have tipped us over our budget, not to mention finding one in such a short time would be nearly impossible. Luckily, a call to Chaser landed us their fiberglass hardtop. The Chaser hardtop, including brackets, weatherstripping, window seals, and a Lexan rear window, weighed in at 28 pounds—a weight savings over the OEM soft top of 31.8 pounds.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Koyo Radiator

The Koyo R-Core radiator uses a 53mm core versus the factory 16mm core, which allows for better efficiency in dissipating heat with its larger coolant capacity. The Koyo radiator’s increased water capacity and improved cooling efficiency will prove beneficial when driving our S2000 during the hot summer months ahead. The Koyo R-Core aluminum radiators are Nocolok brazed for added strength and are designed as a direct bolt-in, retaining the stock mounting points for the shrouds and fans.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Suspension Heat Wrap

Knowing our S2000 was going to frequent the track, we wrapped the outer ends of the ball joints and tie-rod ends with heat-reflective cloth and secured them with wire ties. This simple modification has proven beneficial in protecting suspension components from high-heat stress and is a mod used by many popular Honda race teams, including J’s Racing of Japan.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Volk Wheels and Falken Tires

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

Here’s a close-up shot of one of our Volk Racing Generation 2 forged wheels, 17x9 inches with +40mm offset, wrapped in a Falken RT-615K 255/40-17 tire. Since our S2K is destined to be a street/track superstar, our wheel and tire combination will be playing a dual purpose for the months ahead.

This photo gives you an idea of how aggressive our wheel fitment is when using the factory fenders. Fortunately, the C-West 20mm widebody fenders should take care of our fitment issues. Evasive Motorsports will roll the rear fenders for additional clearance.

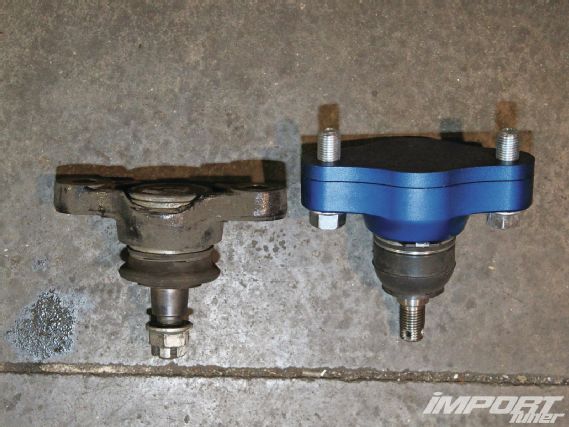

DME Roll Center Adjusters

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

When a car is lowered, the entire spindle and wheel move up in relation to the chassis compared to stock ride height, adding stress on the ball joints. DME roll center adjusters are manufactured physically taller than the stock pieces, allowing your vehicle to keep its original suspension geometry settings while maintaining the lowered ride height. Along with maintaining the stock suspension geometry, aftermarket roll center adjusters avoid unwanted bumpsteer

DME Solid Pillow-Ball Joints

Using solid pillow-ball joints in place of the OEM bushings improves a vehicle’s handling, but has the potential to translate into a rougher ride. We were willing to trade comfort for handling if it meant quicker lap times at Super Lap Battle.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

DME Upper Control Arm Bushings

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

This close-up photo shows a comparison of the newly pressed DME Spherical bushing on the left vs. the OEM bushing on the right. DME uses rubber covers on their bushing kits to prevent dust and contaminants from entering.

DME Rear Toe Control Arms

The factory rear control arms can’t provide enough suspension travel on a lowered vehicle, leaving you stuck with as much as half an inch of toe-in, resulting in poor handling and rapid tire wear. DME rear control arms restore proper suspension geometry on a lowered car, while the spherical rod ends replace the compliant rubber factory bushings for improved suspension response and feedback, and also reduce toe changes during acceleration and deceleration.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

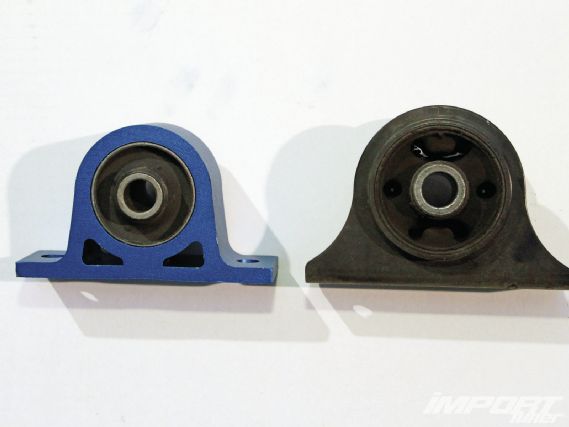

DME Reinforced Differential Mounts

| DME Mount vs. OEM Mount

| DME Mount vs. OEM Mount

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

The factory oil-filled rear differential mounts degrade and crack over time due to age and/or driving conditions. In comparison to the OEM differential mounts, the DME differential mount kit features higher durometer rubber that reduces differential flex, which improves power delivery to the wheels.

Anti-Bumpsteer Kit

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

Bumpsteer is caused by the angle of the steering linkage (inner and outer rod ends) being different than the angle of the lower control arms, and is a common occurrence on lowered vehicles. As the wheel and tire assembly move on the pavement, the difference of the two angles causes the tie rod assembly to become longer and/or shorter, causing a toe-in or toe-out condition, which makes the car suddenly pull from one side to the other. Using the DME bumpsteer kit helped return the steering tie rods to their optimal setting while eliminating the quirky vehicle movement we experienced when driving over bumps and/or making turns.

Evasive Motorsports Halfshaft Spacers

Any time you lower a car, the vehicle’s driveshaft angle changes (depending how much you lower your car), creating an unwanted gap in between the driveshaft roller and spider gear inside the driveshaft. This gap causes the inboard joint to move back and forth, causing stress binding and premature wear. For those very same reasons, we installed a set of Evasive Motorsports aluminum halfshaft spacers to eliminate the gap and increase component lifespan.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Engine Modifications

DC Sports Cold-Air Intake

The DC Sports Cold-Air Intake uses a two-piece design to locate the filter away from the engine bay, allowing cooler outside air to flow into the filter. The kit includes an air filter that requires no oil, therefore eliminating any chance of contaminating the intake pipe or manifold with unwanted oil residue.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Okada Project Plasma Direct Coil Packs

Okada Project Plasma Direct coil packs use a high-power amplifier built into the unit to increase spark current by two times that of the original equipment. The Okada Project coil packs replaced our factory ignition coil system to increase ignition output and supply greater combustion efficiency—two important features we deemed necessary as we attempt to squeeze every last bit of power out of our 2.2L engine.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

DC Sport Header

The DC Sports 4-2-1 one-piece header is manufactured using 409 stainless steel alloy, and is robotically TIG welded and finished in a corrosion-resistant ceramic coating. The DC header’s equal-length primary piping ensures more power throughout the rpm range, and we plan to mate it to a custom 3-inch exhaust system. The header weighs 10 pounds compared to the 22lb OEM unit.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Pure Power Oil Filter

The Pure Power filter, made from 6061 T6 CNC machined forged billet aluminum, is marketed to be 90 percent more efficient than paper or cellulose filters at removing particulates (10 microns and smaller is the size generally considered to be most harmful to engines). The filter can also be cleaned with soap and water and reused due to its stainless steel, dual-woven media filter element. Two Neodymium magnets, located on each side of the filter media, capture metal contaminants that could otherwise harm your engine.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

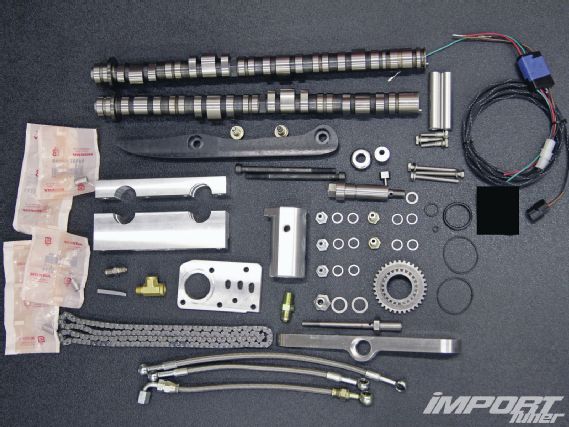

Design Craft iVTEC ECS (Electronic Control Sprocket)

As we continued to focus on building our 2.2L engine to propel our S2000 to a target goal of sub-two-minute lap times at Buttonwillow Raceway, we contacted Gary Castillo, owner of Design Craft Fabrication and mastermind behind the infamous iVTEC system for further assistance. Castillo’s knowledge of S2000s proved invaluable in our quest to build our ultimate street/track machine, as he recently developed an iVTEC system that works with the S2000’s drive-by-wire system. Previous testing with the BC/C-West turbocharged S2000 equipped with a prototype ECS unit made considerable low-end to mid-range horsepower gains over the factory—40 more, to be precise. The BC/C-West machine made a whopping increase of 99.3 hp and 130.4 lb-ft torque at 4,000 rpm, compared to its previous VTEC numbers. After careful consideration, while taking into account our F22C’s high-flowing cylinder head and the dynamic/continuous intake valve timing and overlap control of the iVTEC, we came to the conclusion that the iVTEC system was going to be the perfect addition to our S2000.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

Since we first featured Design Craft’s ECS system in our January ’10 issue, it’s gone through plenty of changes, both physically and mechanically. A side-by-side comparison shows just how much the ECS system has evolved from the first iVTEC prototype to the newest Version 1 system that’s currently available. One major change to the system is the oil retard feed line that originally went from the center of the cam on the prototype unit, which has now been relocated to the top of the valve cover. Castillo states the reason behind the redesign was to promote “fewer oil leaks and eliminate the need to modify the factory hood to clear the previous model iVTEC valve cover.”

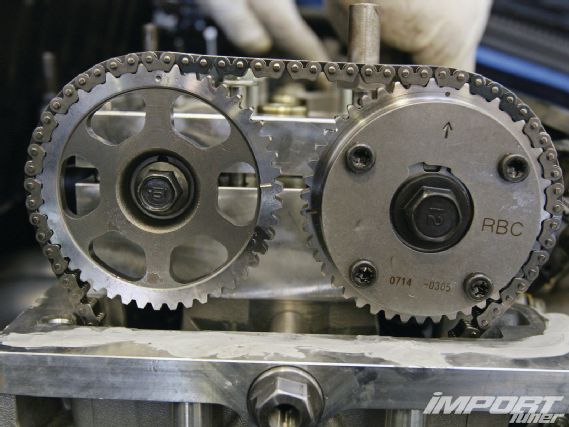

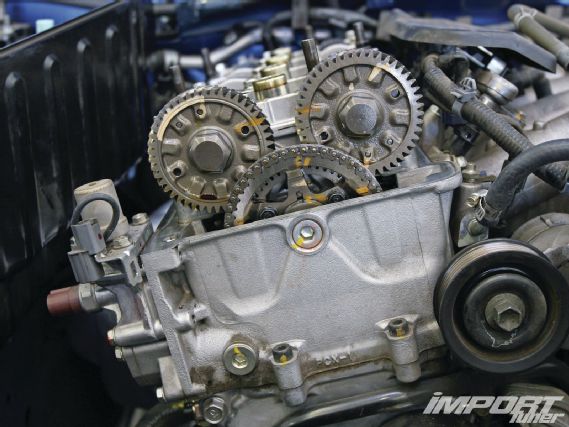

F-series engines utilize a timing chain that spins an idler gear, which in turn makes direct contact with two helical cam sprockets. As the crankshaft spins clockwise, the camshafts rotate counterclockwise.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

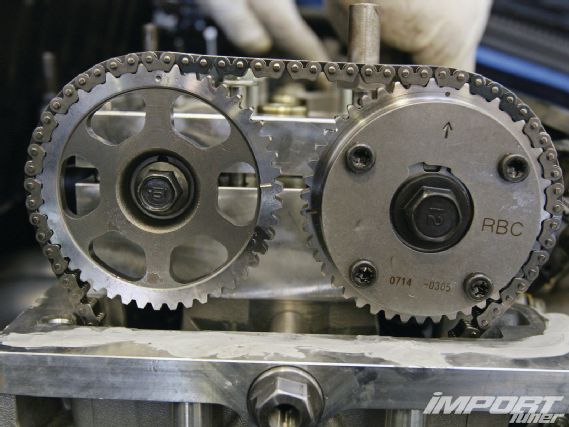

The ECS setup was designed to operate like a K-series engine, with the timing chain only wrapping around the cam sprockets and crank sprocket, thus eliminating the helical gears.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Located directly underneath the number-one cam journal is a 1⁄16-inch oil passage that provides oil to the factory idler sprocket bolt. The iVTEC setup requires using a 3⁄16-inch drill bit to enlarge this oil feed hole. Neglecting to make this modification will cause the iVTEC to not function properly.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

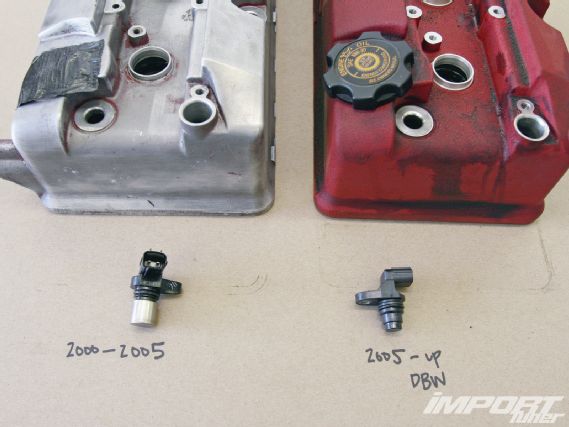

On the left in the photo is an ’00 to ’05 factory magnetic pickup sensor used to monitor the rotation of the camshafts, versus an ’06 to ’09 Hall effect sensor on the right. We’re not sure why Honda decided to switch to a Hall effect sensor midway through the S2000’s production run, but we assume it was because the Hall effect sensor is more accurate at higher rpm, where the F-series is known to thrive.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

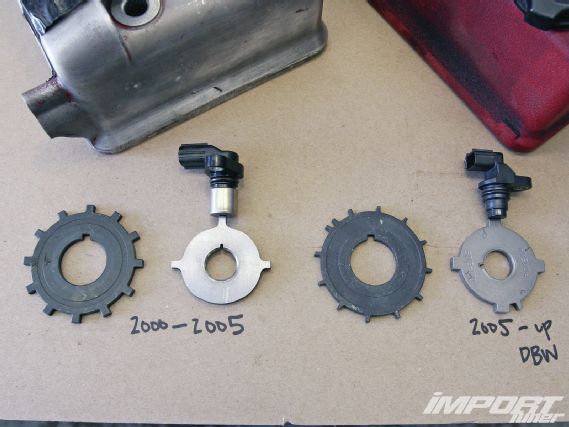

The ’00 to ’05 F-series engines use a 12-tooth crank trigger and dual 4-minus-1 cam trigger for ignition timing. For reference, a 4-minus-1 cam trigger is defined as a full circle with evenly spaced teeth minus one tooth while a 4-plus-1 (used on ’06 and up models) uses a cam trigger that’s got four evenly spaced teeth, plus one additional tooth. The factory ECU uses these cam triggers to read proper positioning and firing sequence of the cams—the engine will not run and will randomly misfire if the wrong one is used.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Project Honda S2000 - Part 2

Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

| Project Honda S2000 - Part 2

The sensor shown in the middle of the photo is Design Craft’s direct replacement piece that’s necessary when changing to the iVTEC system on a drive-by-wire (DBW) vehicle. Based on the mounting depths of the sensor, the DBW and non-DBW cam triggers are different. In order to convert to a Hall effect sensor on a non-DBW valve cover, Design Craft provides a new unit that works with the factory Honda ECU.

On any DBW S2000, you will need to convert to an ’00 to ’05 valve cover due to the drive-by-wire valve cover using only one camshaft sensor on the exhaust camshaft. An ’00 to ’05 valve cover allows the iVTEC system to use the exhaust camshaft to run the factory ECU and the intake camshaft to control the iVTEC.

|

Project Honda S2000 - Part 2

|

Project Honda S2000 - Part 2

Look for the third and final chapter of our S2000 build as we wrap up our iVTEC build, install our body kit, and prepare to shake down the engine as we put the iVTEC to the test on the dyno and the car at the track. Will our S2000 have what it takes to clock sub-two-minute lap times?