Despite heartbreaking news of Honda's decision to end production of the Honda S2000 during its 10th anniversary year, the S2K's popularity has remained strong among the tuner crowd thanks to the sporty appearance and exceptional handling performance of a car considered by enthusiasts as one that doesn't need neck-snapping acceleration to enjoy. Seriously though, how can you not fall in love with today's most popular roadster? It just so happened that my good friend William Law found his true love a few months ago, purchasing an '07 Laguna Blue Pearl AP2 with 80K miles on the odometer.

Without fail, Will always has an unusual way of striking up conversation during his phone calls, but is always guaranteed to start off by asking: "Are you sleeping?" even if it's 2 p.m. on a Tuesday, or, "What are you doing?" when he knows I'm stuck at work at my computer. But interestingly enough, one day I received a phone call that started off on a different note. "Hey, are you sitting down? I just picked up an S2000 and I'm thinking of building it for SEMA and competing in the upcoming Super Lap Battle." Cha-ching! Did he just say Super Lap Battle? My brain immediately kicked into overdrive as visions of building an S2000 track car immediately put a smile on my face.

After a few sit-down meetings with Will, we came up with an ingenious plan of attack: Build the S2K on an enthusiast's budget, with a target goal of sub two-minute lap times at Buttonwillow. Seems simple enough, right? Wrong! Evasive Motorsports' S2000 currently holds the SLB record in Street FR class with a time of 1:56.762. To put Evasive's lap time into perspective, a modified Porsche 993 recorded a best time of 2:04.6 around Buttonwillow's CW13 configuration (the same as SLB uses). The S2K's impressive lap time didn't come easily, as many sleepless nights helped transform it into a reputable time-attack machine with the aid of aero work, over two years of suspension R&D, and hundreds of hours at the track. Unfortunately, our build deadline gave us less than one month before SEMA, followed by a three-day stint before Super Lap Battle.

Why does every build seem to work out perfectly on paper but always turn into a cluster when the clock starts ticking? Follow along as we frantically turn the wrenches to build our S2K.

Project Honda S2000 - Tech-Knowledge

Project Honda S2000 - Tech-Knowledge

In stock form, our S2K clocked a 2:12.348 run at Buttonwillow. The purpose of our lap time was to document how fast the S2K would go with no modification, and we faced a multitude of issues that included brake fade after one lap and OEM Bridgestone Potenza RE070 tires that offered little to no grip. Check out that excessive body roll through the turns!

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

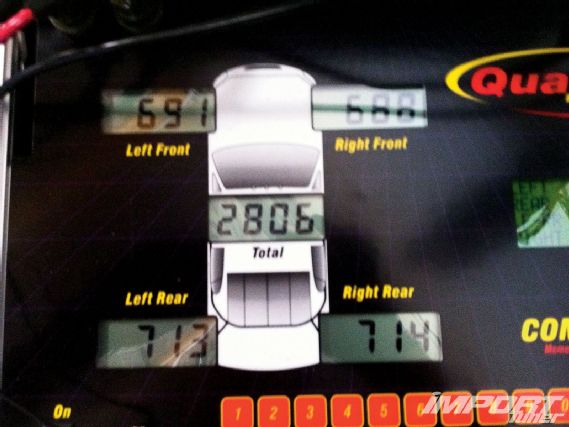

Prior to making any modification, the vehicle weighed in at 2,806 pounds.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Within hours of returning from Buttonwillow Raceway, we began tearing down the car in preparation for SEMA and Super Lap Battle.

Tein Mono Flex Coilovers

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Designed for consumers seeking aggressive handling on the street and at the track, the Tein Mono Flex coilover kit uses an inverted mono-tube shock absorber with 16-way damping force adjustability for compression and rebound. The coilovers use a Micro Speed Valving (MSV) system, which allows the driver to immediately feel the changes made to the suspension once the compression and/or rebound settings are adjusted.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Tein's ability to provide in-house suspension overhauls or customized damping force and/or spring rates for a specific vehicle setup such as ours proved to be a major contributing factor when selecting the right suspension. Tein engineers suggested we revalve our Mono Flex coilovers from the suggested 10kg front and 7kg rear setup to a more aggressive 16kg front and 14kg rear to make full use of our new aero package, increased horsepower output, and 200 UTQG rated Falken RT-615K tires (which fall within Super Lap Battle's regulated 180 UTQG minimum street class rule).

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

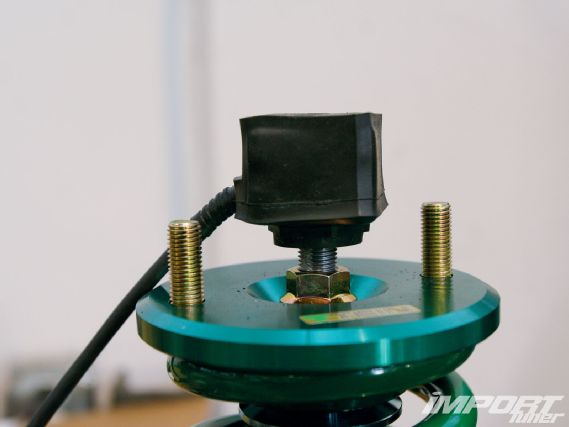

A Tein EDFC (electronic damping force controller) was installed to allow the driver to control the damping force on the fly, to dial in the suspension for the street or track.

Kaaz 1.5-Way Limited-Slip Differential

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Replacing the factory Torsen differential with a Kaaz 1.5-way played an integral part in our build and improved the vehicle's overall handling. Two-way LSDs are designed to provide positive lock motion during both acceleration and deceleration, while the 1.5-way functions similar to a two-way under acceleration, but provides less lockup when decelerating-which provides a more forgiving balance to the notoriously tail-happy S2K. The Kaaz clutch-type differential becomes beneficial in road racing due to its faster lockup capability, stability, and increased predictability through the corners.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Although the rearend only had 80K miles on it, the previous owner neglected to change fluids at the suggested intervals-note the heavy sludge buildup.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

The rearend received a quick parts wash before reassembly.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Ray Nakadate of Kaaz recommends always replacing the carrier bearings when servicing or replacing the differential. Replacing the bearings and seals becomes a cost-effective way to ensure you won't be wasting money on another rearend job within a few months.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Checking for proper pinion depth and/or backlash ensures the differential doesn't make unusually loud clunking noises or experience premature wear.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Ray proceeds with the final step by installing the differential cover and torquing all the bolts to specification as well as reinstalling the axles. The Kaaz limited-slip break-in process required us to drive in a figure-eight pattern for a minimum of 30 minutes with Ray giving us specific instructions to accelerate into the straights and engage the clutch and coast through the turns.

Buddy Club Seats

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Determined to remove weight from the car, we commissioned a set of Buddy Club Racing Spec bucket seats. The seats fit perfectly in the S2K's tight interior while helping to save us almost 16 pounds in weight for the pair with seat brackets.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Here's a comparison between the factory 215/45-17 tire and the Falken RT-615K 255/35-18 tire. Can you say beefy?

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

With minor engine upgrades planned for our F22C, we knew aerodynamics would play a significant role in helping us achieve the lap time we were after. We knew exactly which kit we wanted and made a call to C-West USA to acquire their N1 Spec Version II front bumper, carbon-fiber canards, 20mm oversized fenders, side skirts, and rear bumper. Before you ask if this kit works, the answer is, yes; it truly is a functional kit. The C-West S2000 body kit was designed through extensive track and wind tunnel testing in Japan. Before the kit was sent off to the body shop to receive a fresh coat of paint, we test-fit all the pieces to ensure our new wheel and tire package would clear the wider fenders.

Suspension Techniques Sway Bars

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

There's been plenty of debate on various internet forums about whether the S2K can benefit from using a set of aftermarket sway bars without causing additional understeer. We found it beneficial on our car, knowing our strategy was to use a stiffer suspension and larger-diameter tires.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Springs, dampers, and a proper alignment all play an important role in affecting how a vehicle handles, including a good set of sway bars. Suspension Techniques antisway bars help improve overall handling by reducing body roll and increasing suspension stability when entering and exiting corners. Both front and rear bars are made from solid steel and include polyurethane bushings.

Wilwood Brakes

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Having experienced major brake fade during our baseline track session, we replaced the factory rotors and calipers with a set of Wilwoods. The Wilwood Superlight SL6R forged billet six-piston calipers were designed to be compatible with the OE master cylinder and ABS while providing increased brake capacity and a firmer pedal feel. The kit includes both front and rear two-piece ventilated rotors that are slotted to dramatically reduce rotor temperatures during heavy braking.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Honda's rear hydro-mechanical parking brake caliper design uses hydraulic pressure from the master cylinder for stopping power and an internal mechanical lock within the caliper for the parking brake. The Wilood front and rear rotors measured in at 12.88 inches vs. the factory 11.8 inch (front) and 11.1 inch (rear).

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

The new Wilwood calipers required us to replace the parking brake cable with one that is shorter in length and uses a different design compared to the OEM setup.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

Wilwood provided us with two different compound pads: one for street driving and one for track usage. The Polymatrix BP-10 street pads were installed to drive to and from SEMA, while the aggressive "A" race pads deliver added bite with minimal brake-fade at high temperatures-great for the track.

Spec Clutch

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

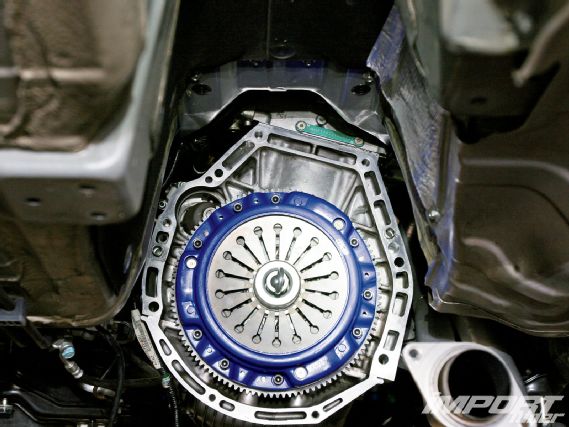

With over 80K on the odometer, the OEM clutch was showing signs of slippage at higher rpm. A quick call to Spec Clutch landed us their Stage 3 setup, featuring a carbon semi-metallic, six-puck, sprung-hub disc and lightweight billet flywheel. The high-clamp pressure plate and double-sprung hub design offered dual usage both on and off the track with its comfortable engagement.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

A quick weight comparison between the OEM and Spec Clutch assemblies including the flywheel revealed a weight savings of 12.8 pounds. The new, lighter-weight Spec setup decreases rotational mass while improving the engine's throttle response.

| Project Honda S2000 - Tech-Knowledge

| Project Honda S2000 - Tech-Knowledge

With neither of us having any prior experience installing an S2K clutch, William made a quick call to Andy Yang of SoCal Motorworks to help install the new unit before we called it a day.

Be sure to follow along in our next issue as we tackle the install of additional suspension components and the infamous i-VTEC setup on our engine, in our quest to build the ultimate street/track S2000.