It's no mystery that the easiest and most affordable way to gain power from a turbocharged engine is with uprated software. From the factory, manufacturers limit an engine's potential to conservative safety margins and to be fuel-efficient for the average consumer. This safety net opens the door for tuners who are able to modify the software in order to maximize the power and boost of the engine.

|

Project Car BMW 135i - Software Tech

|

Project Car BMW 135i - Software Tech

When BMW introduced the twin-turbo straight-six N54 engine in '06, our eyes opened wide. Unfortunately, BMW foresaw the tuners' interest and protected its Siemens DME by inserting program codes that would make it difficult to manipulate. They even implemented a tuner code that sent an alarm to BMW if the software, torque or fueling were tampered with.

The first tuners came to market with piggyback systems, which tricked the factory computer to make more power. These worked well but didn't really address all the problems and it wasn't something we wanted try on our own 135i. We didn't want to risk voiding the warranty, so we waited until a reversible software upgrade was made available, and GIAC was first to strike.

The last time you read about our 135i was in et 9/09, where the weathered front suspension was upgraded with Turner Motorsport end-links and taller front springs from H&R. We also fitted BMW Performance drilled rotors along with cooling ducts to feed more air into the oil cooler and front brakes. Aside from these modifications, there hasn't been much done to the performance besides a BMW Performance exhaust.

|

Flashing the new software is done through the OBD2 port in the car and takes less than an hour

|

Flashing the new software is done through the OBD2 port in the car and takes less than an hour

Although the N54 motor has been around for three years, GIAC took its time working out the maps to ensure the perfect upgrade for the street. The most time-consuming task was apparently ensuring the software drove smoothly throughout the powerband without any surging.

GIAC's torque-based software adjusted parameters such as timing, boost and fuel to increase power progressively from 2300rpm to 6000rpm. Some piggyback systems apparently raise the power curve in a non-progressive fashion, causing the tires to spin on gear changes. Yet the new progressive map guarantees a smooth, strong acceleration. The boost now peaks at 13.5psi, depending on temperature, and stays at this level until 6000rpm. This is compared to the factory's 5-6psi.

|

Project Car BMW 135i - Software Tech

|

Project Car BMW 135i - Software Tech

With the new GIAC software, we saw an improvement in power, torque, throttle response and engine speed, yet didn't seem to suffer reduced fuel economy or a reduction in engine manners. The GIAC flash also eliminated the top speed limiter, increased the rev limit to 7200rpm and removed the tuner code, which alerts BMW if the motor has been tampered with. This does not affect the car when it's serviced at the dealer, and the ECU retains all the protection granted by the factory.

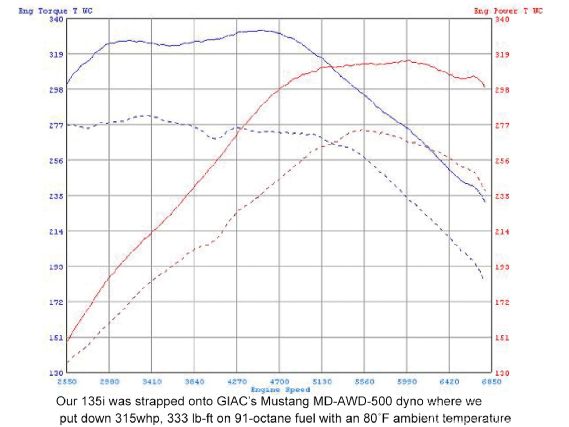

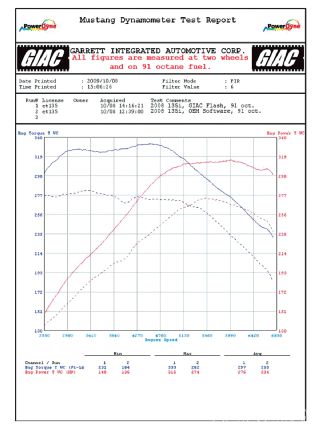

We started in the morning, strapping our 135i on GIAC's dyno in its Irvine, CA facility. The Mustang dyno measured three consistent pulls with a max baseline of 274whp and 282 lb-ft.

We then left the car on the dyno as GIAC engineers plugged their laptop into the car using the OBD2 port to access the ECU. Before flashing the software, GIAC scanned the computer for faults and were automatically sent to its in-house database. This process is completed for all software flashes done by any GIAC dealer around the world.

|

Project Car BMW 135i - Software Tech

|

Project Car BMW 135i - Software Tech

Because the dealer recently serviced our 1-Series, it had BMW's latest files, which are constantly updated to remove bugs in the system. GIAC had to rescan the ECU and adapt to the new data before uploading its program. This process took a little over an hour, but for cars without the updates, GIAC can flash in as little as 30min.

We then started the car on the dyno again and it ran three times. All three pulls were similar, with the max achieved being 315whp, 333 lb-ft. This represented a 41whp and 51 lb-ft gain and reflects the stage 1 software with stock exhaust (since our exhaust added no extra power when we dynoed it previously). According to GIAC, they're developing stage 2 software to work with aftermarket downpipe and intercooler upgrades to take full advantage of the N54's potential.

|

Project Car BMW 135i - Software Tech

|

Project Car BMW 135i - Software Tech

Priced at $800 MSRP, this is a great bang for the buck and it works on all 135i, 335i and 535i cars. In the future, GIAC will also have its handheld switching module compatible with BMW software, so you can switch between different octane levels, valet mode and stock mode.

GIAC In the early '90s Garrett Lim spent time drag racing BMW M3s and VW GTIs. With his rivals trying every other type of hardware upgrade, Garrett discovered the advantage of software tuning, learning to modify not just ECU maps but code as well. He spent his nights after school tuning the cars at the strip. Eventually, Garrett Integrated Automotive Corp (GIAC) was born. Garrett then collaborated with AWE Tuning on several projects, providing software for AWE's hardware on several VW/Audi vehicles. Now GIAC offers software for most European makes, including Audi, VW, BMW, Volvo, Mercedes, Bentley and Porsche. Software flashes are just a part of itsproduct line and they also provide custom tuning for special projects on a case-by-case basis (giacusa.com).

|

Project Car BMW 135i - Software Tech

|

Project Car BMW 135i - Software Tech