| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

On October 30th, as the automotive world worked tirelessly to prepare for the biggest event of the year--the SEMA show--I too was caught up in a time crunch, wrenching on my Subaru STI... but for a different reason. The STI had just returned from a shakedown session at Buttonwillow Raceway in preparation for our Nov 11th Import Tuner STI vs. EVO shootout. The car ran well, but was hardly track-ready as I scrambled from shop to shop, attempting to gather the necessary components to make the deadline for competition. Since I was selected to be one of five car owners representing the Subaru class, I'd better be damn sure that I was prepared to wage war.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Recap Buttonwillow Raceway Shakedown

NASA held an open invitation track day at Buttonwillow Raceway, using the Super Lap Battle clockwise configuration CW13. The car encountered continual issues with the charge pipe blowing off after every lap, and its 235/35-18 tires had a slight rubbing issue towards the rear fenders, but nothing to be too concerned about. The STI showed signs of slight understeer, but with some minor adjustments we were able to induce the rear to slide out. My driver for the day--and for the upcoming STI vs. EVO shootout--was none other than in-house wheel-man Andy Hope who, after a few laps, stated "the car's a handful and slides all over the place... but is fast as shit, and totally predictable on the track!" The feedback was promising as the TEIN engineers helped me continuously throughout the shakedown sessions, making minor adjustments to the toe and caster settings before calling it a day.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 01:Sunday Nov. 2

The early morning began with some routine maintenance and replacing of engine fluids. The brake pads were replaced with a set of Hawk HP+ and stock fluid was bled for Motul. In anticipation of using this aggressive street/race pad, I picked up some silicone brake duct hose to install onto the car's Chargespeed carbon fiber brake ducts. If you noticed in our previous photos from the shakedown session, the STI was lacking aerodynamics, which included missing side skirts and a rear wing. With the help of Chargespeed, we were able to acquire a full body kit along with a pair of larger 20mm front fenders. Finish Line Auto Craft in Gardena, CA sprayed it factory Aspen white, while I ran back home to continue piecing the car together. The factory rear wing was re-attached on a carbon trunk to promote more rear down force. Without the wing, the STI's balance seemed to be upset; the rear end was a bit too squirrelly through the turns.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 02: Monday Nov. 3

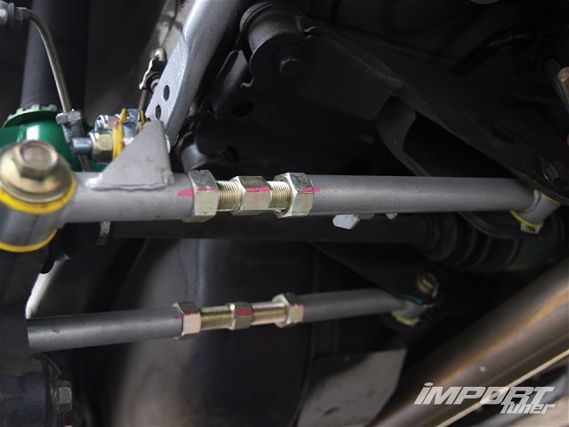

Whiteline suspension played a major role in getting the vehicle to its current status as many of the parts began to roll in one at a time. I began working on the front of the car and made my way back. The first items to tackle were the Whiteline anti-lift kit, steering rack bushings, and roll center adjusters. With a simple upgrade of these three items, a noticeable difference in handling performance can be felt on the track. The Whiteline transmission cross member bushing was also easily swapped in within minutes.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 03: Tuesday Nov. 4

I begin with the installation of the Whiteline front and rear 27mm sway bars. While many suggest this diameter is too aggressive for the STI, we found that using larger-diameter sway bars with bigger tires creates more oversteer and brings the STI's rear end around like a RWD vehicle, remedying understeer problems most AWD vehicles suffer on the track. Both front and rear sway bars were matched up with a set of spherical bearing end link kits to tighten up the suspension.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 04: Wednesday Nov. 5

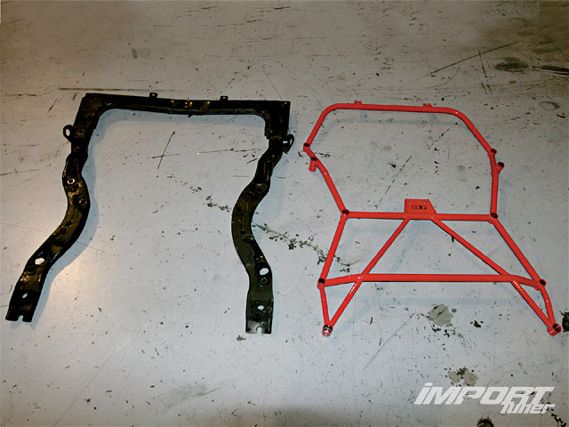

In a quest to further stiffen the chassis, I paid a visit to M1 Fabrication & Development in Brea, CA, to pick up a chromoly sub-frame brace. The lighter and more rigid brace uses the factory pickup points and easily bolted into place. Not only does the brace aid in stiffening up the chassis, but it brings the vehicle's front-to-rear weight ratio to a more even level. With some skillful body contortion, I was able to mount and bolt the sub-frame brace onto the car using jackstands.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 05: Thursday Nov. 6

After days of wrenching, my back, neck and shoulders feel ready to fall off. I take the opportunity to perform some lighter duties on the vehicle by installing the Beatrush Pitching Stopper and Samco Ancillary hoses. The OEM pieces just couldn't stand up to the repeated on-track abuse my STI was subjected to.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 06: Friday Nov. 7

Rise and shine! I begin working on the rear of the car with the Whiteline Differential Lock Support Kit, before moving on to the rear adjustable control arms. The arms proved to be an invaluable item for fine tuning the Subaru's caster, camber and toe settings. In conjunction with the rear control arms, a Whiteline Toe Adjuster Locking kit, which replaces the stock toe-adjuster, was bolted into place. The locking kit eliminated the movement of the rear arms where severe driving has a tendency to shift the factory toe adjusters out of their designated position. Its two o'clock in the morning and I'm just about out of Redbull and cigarettes. I'm sitting on the concrete floor and thinking to myself, "What the hell I have gotten myself into?"

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 07: Saturday Nov. 8

I received a call from the body shop that the Chargespeed kit was painted and ready for pickup. I trick my girlfriend into going with me and steal my dad's truck to load the pieces into the bed. On my return trip, I make a pit stop to pickup a set of Cusco engine and transmission mounts. The mounts would play an important part in keeping the engine from jumping around in its bay. A close-up of both factory and aftermarket mounts reveals just how weak the original mounts were. After receiving a tongue lashing by my mom on why I didn't pay more attention in Japanese class when asking her to translate the instruction manual, I spend the next few hours lifting the engine and replacing the stock mounts with the new Cusco pieces.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 08: Sunday Nov. 9

It's coming down to the wire, as I have a dyno session scheduled for the following day. I yank my FP Green turbo out of the car to find the inlet and exhaust housing covered in oil. This was not something I was hoping to see, one day before my test and tune session. A quick analysis of the situation offered three possible explanations: The first was a bad oil return line, the second was too much oil feeding into the turbo, and the third put the turbo on its last leg. Luckily, I had planned to replace the Green beforehand, and test the new Tomei M7760 turbo (a detailed review of which, to come in a future issue of 2NR), which I bolted into place on a wrapped Tomei 4-2-1 equal length header. One word of advice: wear gloves and shitty clothes before you even decide to touch fiberglass header wrap!

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 09: Monday Nov. 10

I fired up the STI for the first time in over a week and immediately noticed how much NVH (noise, vibration, and harshness) was produced using the Cusco mounts. The car was dropped off at the dyno facility to dial in the HKS V-Pro and new Tomei turbo and header, and after a full day of tuning, was brought back to my parents' house to bolt on the new Chargespeed body kit. Notice the width difference between the factory front fender and 20mm wider Chargespeed unit. The large sized fender will come into play when the STI sports a wider set of wheels and tires.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Day 10: Shootout!

With some simple hand tools and blood-red eyes from lack of sleep, the STI was aligned to the best of my knowledge, before setting off at 4 am and driving a brisk 155 miles to Buttonwillow, and just barely making the morning's drivers' meeting. With so many changes that had taken place on the car since our shakedown sessions, I wasn't sure what to expect. One thing was for sure; Andy was going to have one hell of a time getting used to this new track monster! While preparing for the morning's first session, I was still in chaos mode as I scrambled to mount the necessary fifth-point harness and some finishing touches, causing Andy to miss a large portion of practice. After the guys from TEIN aiding in setting up the newly revised suspension, Andy hopped into the car to gather some seat time. Watching the car come out of the "Club Corner" turn and enter "Bus Stop", my ass cheeks puckered up ever so tightly as the car began wagging its tail like a rabid dog. Exiting, the car was literally sliding into "Truck Stop" as Andy manhandled it back to the start/finish line.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Upon entering the paddock area, Andy jumps out of the car and screams "The car wants to drift in every corner! It's got WAY too much oversteer!" "Great," I thought to myself, "I've built a fantastic drift car..." After some adjustments to the sway bar settings, and lower tire pressure and spring preload adjustment in the rear, the car was sent back out for its first official lap time of the day, just minutes before the first qualifying session ended. Andy managed to get three laps in, with a best time of 2:01.644, before the checkered flag ended the run group. As the car coasted into the paddocks, the first thing I noticed was thick webs of molten black rubber covering the rear of the car; the rear fenders were cutting into the wider, 245-series ContiSportContact 3 spec tires. Upon further investigation, I noticed major cording of the tires, exposing the inner lining on both sides--a problem no one else running the Contis was having; meaning the tires were rubbing excessively against the wheel wells of the STI. Without replacement tires available, the car missed the second qualifying session as I looked on in discouragement.

| Building an STI in 10 Days - Tech Knowledge

| Building an STI in 10 Days - Tech Knowledge

Mike Chang of Evasive Motorsports offered a hand. Using a rubber mallet, I began yanking off the over-fender trim as he joined in the carnage by hammering out the rear fender to clear the tires. With spectators looking on in dismay, and Carter screaming, "Damn Scott... you're down for your shit, messing up a car like that!" we had missed our last qualifying session but had just enough time before the final relay event to bang out the rear fenders and hack away at the front Chargespeed over-fenders in order to squeeze a set of 265/35-18 Continental tires up front while rotating the original 245/35-18 set to the rear. It was a risky decision to make, as the center differential would be pissed off from the offset in tire size, but it was a sacrifice that had to be made for the Subaru team not to be short one competitor. We made the grid... and were smoked by the EVOs as a whole, but surprisingly, the STI managed to take First Place in its class. Was it all worth it? It was foremost a learning experience. For now, all I can think about is going back to my parents house this weekend--where the STI now sits on jackstands--and modifying the rear fenders to fit 265/35-18 tires on a 18x 9.5 inch wheel full time, before going back out to the track in another month. When will it ever end?