| Project WRX V.08 - Tech

| Project WRX V.08 - Tech

It's down to the final rush for SEMA and Project WRX V.08 just came back from the paint shop in the all-too-SCC flat black, a tribute to our old Krylon-special STi. This all started back in the day, when Coleman decided to rattle-can his Project Silvia flat black because he couldn't bring himself to go to a body shop or stare at the huge patch of Bondo on his quarter-panel. And so, a trend started out of cheapness.

Not to be outdone, ex-editor Oldham followed suit with a perfectly good 2004 STi and a rattle-can party/barbeque. While the results weren't quite as stellar, the car was still nonetheless stunning, that is, until some neighborhood kids decided to turn the car into a tic-tac-toe chalkboard.

| The vacuum-formed Airtab vortex generators were designed for flat surfaces, like on a tractor/trailer. To mold the pieces to the WRX's roof curvature, we first covered the sections in foil and marked the mounting locations. Then using Bondo and some pressure, we added material to the trailing end of the Airtab. Once dry, the extra Bondo peels away from the smooth plastic sides easily. With some clean-up and paint, the vortex generator sticks to the roof with the double-sided tape already attached to the bottom.

| The vacuum-formed Airtab vortex generators were designed for flat surfaces, like on a tractor/trailer. To mold the pieces to the WRX's roof curvature, we first covered the sections in foil and marked the mounting locations. Then using Bondo and some pressure, we added material to the trailing end of the Airtab. Once dry, the extra Bondo peels away from the smooth plastic sides easily. With some clean-up and paint, the vortex generator sticks to the roof with the double-sided tape already attached to the bottom.

While most of us are not up for ruining a perfectly good paint job, something had to be done for a SEMA show appearance. Our car was to appear front and center in Subaru of America's booth and, although we're not really show-car dudes, we knew they weren't expecting a near-stock car to appear. When we first negotiated booth space with Subaru, we were asked if we wanted to team up with West Coast Customs. Yup, the guys from Pimp My Ride. Thanks, but we'll be alright.

We knew we weren't going to go with a crazy custom body kit and underbody lighting, just a few simple changes that would transform Project WRX V.08 dramatically. So the decision was made to flat black our Subaru professionally (Krylon won't cut it at a show the level of SEMA). It's now become almost a tradition and a sign that a project car has received the SCC touch. The BASF two-stage Carizzma Flat Black paint and white Prodrive wheels will surely stop anyone from mistaking our WRX for a Camry.

We continued with our thus-far mostly cosmetic build-up with a prototype carbon fiber hood from Crawford Performance. Like many on the market, it's a single piece of carbon fiber overlaid onto a fiberglass copy of the factory hood bracing. Due to the integrated hood scoop, the molding is complex and multi-layered. It's easily 20 pounds lighter than the stock steel hood, which will have a good impact on our CG and front-to-rear weight distribution.

| The Crawford carbon fiber hood has an accurate copy of the stock underhood ribbing. This makes drilling and mounting of the stock intercooler ducting pretty straightforward, although the weight of the stock hardware causes more strain on the composite hood.

| The Crawford carbon fiber hood has an accurate copy of the stock underhood ribbing. This makes drilling and mounting of the stock intercooler ducting pretty straightforward, although the weight of the stock hardware causes more strain on the composite hood.

To duct the incoming air onto the top-mount intercooler properly, the original ducting hardware had to be taken off the stock hood and remounted onto the fiberglass structure. Crawford made such an accurate copy of the reinforcement ribbing structure that all the original screw and poppet holes were replicated in the fiberglass. Since there was minimal deformation in the fiberglass, mounting the stock ducting was just a matter of identifying which holes needed to be drilled, and doing so carefully. The same can be done when mounting the OE cardboard fabric underhood heatshield--which is highly recommended, since it helps to direct heat away from the hood itself. The only problem with retaining the OEM ducting is the added weight the hood has to support, which causes high-speed vibrations.

At the rear, the hulking stock wing was taken off to reduce weight. In its place went a JP USA universal flexible mini-lip spoiler that effectively acts as a gurney flap to rotate and energize airflow coming off the trunk. Even if it does little aerodynamically, the JP wing features an improvement in weight savings versus the stock piece. This significant change also means that Project WRX V.08's torsion trunk springs need to be changed for the stock wingless Impreza parts, so the trunk won't pop open like a catapult.

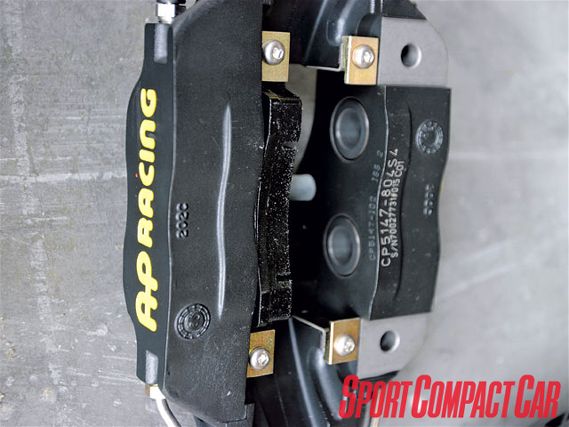

| Unlike the front caliper, the rear unit uses the same size pistons so that the caliper is not rotation-specific outside of how the hydraulic lines are routed. This makes the unit easier to use with manufacturers' mounting constraints.

| Unlike the front caliper, the rear unit uses the same size pistons so that the caliper is not rotation-specific outside of how the hydraulic lines are routed. This makes the unit easier to use with manufacturers' mounting constraints.

On the roof, we added a row of universal vortex generators from Airtab. These vacuum-formed pieces attach to the trailing edge of the roof, help reduce the low-pressure pocket behind the rear window (which causes drag), and provide smoother flow for the spoiler. They're designed to mount onto smooth surfaces, so a little Bondo work and spray paint was needed. Luckily, flat black isn't hard to match with Krylon's existing line of colors.

Interior

On their third tour of project car duty after Project `04 STi and '06 WRX, our Sparco Milano reclineable seats were installed. Unless we absolutely believe we need the lateral support, we often avoid changing the stock seats on street cars, since they're safe, designed to work with stock belts and the seating positions for drivers of many sizes. But showing up to a car show with stock seats is a taboo even we couldn't break. The switch to heavy, steel-framed recliners was actually a fair trade. Modern OEM seats now are so laden with seat heaters, weight sensors, airbags, active head restraints and wiring, that they weigh more than most aftermarket recliners. So, for the same weight, we now have more support without the seatbelt placement impediments typically encountered with heavily bolstered buckets.

| Project WRX V.08 - Tech

| Project WRX V.08 - Tech

Our original seat brackets--which fit the past three generations of Imprezas, but not the new `08--were modified by Scott at SPD Metal Works in Placentia, California, to line up to the new locations. The newer Impreza's wider tranny tunnel meant that all the bolt points were relocated to a narrower width, even though most mounting points retained a similar geometry. Our new gangster-low seating position is great for taller drivers, but it puts the center console and armrest in the way of large arm motions.

| The new 13-inch floating rotor uses an aluminum hat that allows for axial and radial expansion so the rotor always stays aligned with the caliper and pads. This reduces pulsing as well as relieving stress from the different thermal expansion rates of the iron rotor ring and aluminum hat. The AP Racing rear big brake upgrade uses a four-piston cast aluminum caliper, a 13-inch two-piece rotor and beefy prototype caliper bracket. Our prototype unit uses an aluminum hat, which also acts as the drum for the integrated parking brake. Production units will use a more robust steel hat.

| The new 13-inch floating rotor uses an aluminum hat that allows for axial and radial expansion so the rotor always stays aligned with the caliper and pads. This reduces pulsing as well as relieving stress from the different thermal expansion rates of the iron rotor ring and aluminum hat. The AP Racing rear big brake upgrade uses a four-piston cast aluminum caliper, a 13-inch two-piece rotor and beefy prototype caliper bracket. Our prototype unit uses an aluminum hat, which also acts as the drum for the integrated parking brake. Production units will use a more robust steel hat.

Our final addition to the interior was a stealthy window film application from 3M. Originally designed as a means of keeping houses cool, the 3M Crystalline window tint was refined for the curved surfaces of automotive applications with almost no visual distortion. While we normally frown on window tinting since it reduces day and night vision (as well as being a potential headache with law enforcement depending on where you reside), the heat-rejection advantages are great when parking the car under the sun or saving gas on A/C usage.

Jeffrey Kalmar, of Prescription Windshields in Chandler, Arizona, came all the way out to Southern California to apply this soon-to-be-released Crystalline 70 material. Like most tints, 3M Crystalline will reject 99.9 percent of UV radiation, which saves black seats from turning purple and keeps composite parts from sunlight deterioration. The material also allows 68 percent of visible light in, which conforms to DOT standards. This means the tint can be applied to all windows, including the windshield. It's also clear enough to be hardly noticeable. The main advantage is the 50 percent rejection of solar energy.

Electronics

In case you're wondering, no, hell hasn't frozen over. We're messing with audio equipment in a project car. There's a reason for the upgraded in-car entertainment system and it doesn't have anything to do with cruising or show-car looks. Early in Project WRX V.08's SEMA build, Editor Leh came up with the great idea of tripling everyone's workload by having it filmed. The concept was to edit the tapes into a short video segment (available for viewing on our website) and then loop the video on a huge display next to the car in Subaru's booth for extra promotion and coverage. The only problems we had to conquer were how to best play the video at the show and how to make sure people in the crowded Las Vegas Convention Center hall could hear anything at all.

We chose Pioneer's AVH-P4900DVD head unit, because it's one of the most affordable and reputable video-capable units out. It can play DVDs, output video to an external screen and has a video input, which is a nice option that will allow us to test an in-car video-overlay data acquisition system at a later date.

| Project WRX V.08 - Tech

| Project WRX V.08 - Tech

With the video portion covered, we turned to audio. As we were temporarily turning Project WRX V.08 into a DVD player and speaker system while it sat at SEMA, sound quality was paramount. The video would have to be played loud to be heard at the show and we didn't want any distortion. We used 250W-max Pioneer 6.5-inch TS-C160R component speakers up front (three pounds versus 2.25 pounds stock) and 260W-max 6.5-inch TS-D161R two-way speakers in the rear doors (2.75 pounds versus 2.5 pounds stock). Both feature Kevlar cones for damage resistance during large movements (i.e. loud volumes) and a healthy 90dB/W/m sensitivity rating. This is important, because a higher sensitivity rating means that a speaker will be able to play a louder note with the same amount of power. This was essential to us--we weren't going to mount a four-channel amplifier permanently.

| SPT's cat-back exhaust system uncorks much of the stock WRX engine's potential by reducing the backpressure the stock turbo has to push against. The 2.5-inch tubing extends the entire length of the exhaust and the SPT system weighs five pounds less than stock by deleting the stock resonator and using smaller mufflers with less packing material.

| SPT's cat-back exhaust system uncorks much of the stock WRX engine's potential by reducing the backpressure the stock turbo has to push against. The 2.5-inch tubing extends the entire length of the exhaust and the SPT system weighs five pounds less than stock by deleting the stock resonator and using smaller mufflers with less packing material.

Surprisingly, all four speakers only added up to a two-pound total increase, even though they feature much larger magnets. The stock WRX speaker mounts are pretty good for factory units, featuring sound-absorbing foam surrounds against the door panels. We simply separated the brackets and dropped in our Pioneer speakers.

When we installed the 1000W-max Pioneer TS-SW1041D Premier 10-inch slim subwoofer (10.5 pounds) and PRS-D2100T Premier amplifier (6.5 pounds), we resisted going with anything heavy or permanent. The Pioneer slim subwoofer uses a thin design to minimize weight while keeping sound quality high (and excessive booming low), and requires a subwoofer box between 0.35 and 0.70 cubic feet. We got a simple sealed MDF box and installed it in the trunk. This makes the entire system easily removable.

Brakes

Our last SEMA additions weren't so cosmetic. Just two weeks before the show delivery date, Stillen/Brake Pros came through with the prototype four-pot rear addition to our AP Racing front brake set-up. Even though the front brake kit is identical to the AP offering for previous WRX models, the completely redesigned rear suspension required a new kit. Brake Pros used the basic model AP Racing AP5100 cast aluminum caliper with non-staggered 38.1mm pistons as the base. This makes the calipers easier to manufacture since they're not directional. All the pistons are sealed for better street life.

| The dual muffler and double wishbone rear suspension design of the new WRX sedan limits the amount of space available for large diameter piping. In order to clear the rear differential and lower control arms, the exhaust is routed close to the ground. One design flaw we see is the placement of the b-pipe-to-rear-pipe exhaust flange, which sits at the lowest point in the car just below the differential. A three-inch exhaust system will be hard to fit under the new chassis.

| The dual muffler and double wishbone rear suspension design of the new WRX sedan limits the amount of space available for large diameter piping. In order to clear the rear differential and lower control arms, the exhaust is routed close to the ground. One design flaw we see is the placement of the b-pipe-to-rear-pipe exhaust flange, which sits at the lowest point in the car just below the differential. A three-inch exhaust system will be hard to fit under the new chassis.

The 330x25.5mm rear rotors are a full-floating rotor design (like the fronts), which uses an aluminum hat and cast iron rotor ring allowing better rotor-to-caliper alignment for potentially less pulse and improved resistance to permanent thermal deformation. Production models will use much lighter caliper brackets and a steel hat for better durability, since the WRX uses an integrated drum parking brake inside the rear rotor hat. One major advantage of the AP Racing big brake kit is the addition of a directionally vented rear rotor, which is far more effective at keeping the rotors cool compared to solid stock rotors or straight-vaned designs.

In terms of balance, our four-wheel AP Racing set-up seems to be slightly more rear-biased since both front and rear rotors share the same 330mm (13-inch) rotor diameter and the rear piston area has increased proportionately to stock. The front pistons are now only 18 percent larger than the rears. In the case of most modern cars, like the 2008 WRX, minor changes in piston sizing for proper front-to-rear bias can be compensated for, as these cars now have Electronic Brake Force Distribution (EBD.)

Essentially, EBD acts as an automatic proportioning valve that redistributes hydraulic brake pressure to each wheel, optimizing braking force at each corner while maximizing traction during threshold braking. But the automatic biasing is only a minor stopgap and will not compensate for a gross difference in brake bias. This is especially so when the entire brake system has been modified with larger parts as the EBD operation is calibrated for stock brake components. In some cases, EBD might cause more of a problem, like in an overamplified brake system, which requires less line pressure for the same amount of braking force. Since EBD is not-self correcting, it might direct too much braking force to a given corner, thus making the ABS intervention work harder and longer.

Based on our street driving impressions so far, the four-wheel AP Racing brake upgrade has taken all the sponge out of the stock brake feel without much change in brake bias. The larger rotor diameter, more aggressive pad compound and stainless steel braided brake lines give an aggressive initial bite, but the pedal remains stiff and easy to modulate. This is well-suited for track applications, but may require some getting used to on the street.

Exhaust

Subaru's use of a new dual muffler design on the Impreza sedan platform is potentially troublesome for tuners. While the two tips might add a sense of value to the new car, the added weight and space constraints of the new rear suspension limit the size of aftermarket exhaust piping.

We replaced the small diameter stock exhaust system from the catalytic converter back with SPT's exhaust system. The direct bolt-on kit uses all the stock factory hangers and OEM thickness flanges so the stock exhaust flex bolts fit without any modification. The smaller, less insulated mufflers and the deletion of the post-cat resonator help reduce weight. SPT even went as far as using hollow tubing for the hangers to save weight. The new exhaust weighs 39 pounds, compared to the stock exhaust's 44-pound weight. The new 16-gauge 304 stainless steel and 409 aluminized mandrel bent tubing has an increased diameter of 2.5 inches all the way to the mufflers, compared to the 1.5-inch, 19-gauge stock B-pipe. The backpressure reduction amounted to a maximum 51 wheel-hp gain and now puts down a total of 224 wheel-hp to the ground with the K&N Typhoon air intake. One downside of the larger exhaust piping is the lack of ground clearance, especially near the rear differential, where the rear section flange comes uncomfortably close to the ground.

Next time, we'll dump most of this sissy cosmetic madness and revert to a fast, functional form.