| Project Toyota Corolla AE86

| Project Toyota Corolla AE86

In the last installment of Project Corolla, we dialed in a set of custom Ground Control coilovers, then figured out spring rates and ride height adjustments to make the suspension work on the track. We chose 6kg/mm springs in front, in conjunction with specially valved Koni twin-tube dampers and 4kg/mm rear springs, mounted on monotube shocks. While we've had some issues with the overall amount of suspension stroke, we've made the setup acceptable-for the time being.

Roll, Squat And Bind

One trend among tuned Corollas is the tendency to lower them by too much. Even with spring rates sufficiently high to enable proper suspension function with such a short stroke, there are severe alterations to the stock geometry. What little stroke there is becomes confined to one extreme of each control arm and link's arc of motion. Also, when the springs are stiffer than the chassis, the chassis does all the flexing.

Fixing geometry problems in most modern cars with independent rear suspension is a matter of modifying the bushings or pick-up points to make the stock camber and toe curves work. Corollas are anything but modern and independent. Ironically, we had to steal tricks from muscle car and truck gurus to make our live axle stick and turn.

With a live rear axle, lowering the car does two critical things. First, the pinion angle is changed, so that, in static state, it's already pointing down. It does so even more when the car squats under acceleration (assuming it has enough power for the job). This means more resistance at the differential input shaft when the driveshaft yoke is contorted. More importantly, most cars are like the Corolla and have unequal lateral links. The anti-squat reaction from these links is further increased, since the lower link is now nearly parallel to the ground, while the short upper arms point up at a steep angle, pushing the instant center far below the center of gravity.

There really isn't a good fix for this without whipping out the welder and acetylene torch, but we're trying to solve it with an assortment of adjustable links, bars and brackets from Whiteline Automotive. It seems the AE86's popularity has stretched to Australia and Whiteline has invested a good deal of time developing and racing the platform, as well as writing papers on proper set-ups for it. Based on this experience, the company has developed a range of products that allow a Corolla to be adjusted for a variety of purposes.

To correct the pinion angle and reduce anti-squat reaction, we replaced the stock unequal-length lateral links with adjustable units. These are steel pieces with polyurethane bushings inserted in each end, which keep out some noise and vibration (unlike a heim joint). The lengths of the arms are adjusted with a threaded center section and jam nuts. There are many ways to screw this up when fiddling with the lengths, so we kept it simple. We put the lower links at the stock length to preserve the original wheelbase and adjusted the upper arms to force the pinion angle parallel to the ground. Depending on how far a car is lowered, there's a chance the upper arms will contact the axle housing under compression, so we had to move the axle through its range of motion to double-check. Otherwise, there would be suspension bind issues.

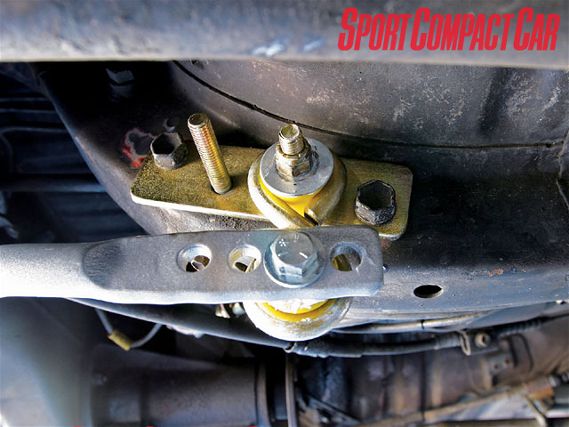

| Whiteline's front and rear anti-roll bars come with polyurethane bushing lined end-links, as well as reinforced brackets that bolt to the chassis with different pick-up points, preventing end-link bind and the bar coming into contact with the body.

| Whiteline's front and rear anti-roll bars come with polyurethane bushing lined end-links, as well as reinforced brackets that bolt to the chassis with different pick-up points, preventing end-link bind and the bar coming into contact with the body.

Adjusting the lateral link arm's length to control pinion angle also has an added benefit of altering anti-squat characteristics. Since the upper arms are at such an extreme angle and are at the upper range of their arcs, any extension will lessen the angle between the top and bottom links noticeably. This helps to reduce binding resistance and anti-squat. But there is a limit-extending the upper arms too much will push the pinion angle up, as well as increase the likelihood of axle contact. We could take out more anti-squat by shortening the lower arms (which allows the upper arms to be extended further without compromising pinion angle), but then there would be changes to the wheelbase, which we're not ready to play with yet.

Anti-squat is not always a bad thing. Drifters take advantage of it to help aggravate the car and break the rear tires loose to initiate a slide. This method is obviously more useful with greater grip and power. If we were drag racing, we'd leave it at a slight downward angle, so as the car reaches full squat from launch, the pinion lines up with the driveshaft. But we aren't drag racing and we have no power.

For those with power and/or drag racing aspirations, Whiteline also makes a set of brackets for the axle side of the lower lateral links, which allow the back end of the lower link to be remounted at two even lower positions. By lowering the pick-up point, the angle between the arms increases, adding more anti-squat without altering the pinion angle. We installed these brackets to each axle end, but kept the stock end-link position, so we could at least keep the lower link parallel to the ground if we decide to lower the car more in the future and change the pick-up points.

We also replaced the front and rear anti-roll bars. Although the stock bars worked well enough, the added roll stiffness is a good thing when running fairly soft springs, it helps with faster transient response. But a lot of roll resistance isn't necessarily desirable. As the car now sits on Hankook Z212 street tires, we wanted a limited amount of roll resistance since street tires have less traction. Too much would overload the outside tires in a turn, while not allowing the inside tires to provide maximum contact, causing the car to slide prematurely.

Whiteline offers two rear bars and three front bars-all solid. The rears are 18mm in diameter (with and without adjustable blades), while the fronts are 24mm (with or without adjustable blades). And there's also a monster non-adjustable, extra-heavy duty 27mm bar that looks more appropriate for something bigger-like a 240SX. We're not sure why such an item is available. Even on race tires, a large front bar should make any car push severely. We opted for the adjustable fronts and rears, adjusted to the least resistance for street tires (and decided to save the monster front bar for testing, when we have a lot more rubber). Both bars have Whiteline end-links with polyurethane bushings and reinforced body mounting brackets. For this particular application, the well thought-out brackets offer two attachment points for the end-links.

Depending on which of the four adjustment settings chosen, you can use a different attachment point to avoid end-link bind and body contact. We have noticed that, depending on how much twisting resistance there is, the front bar might have clearance issues with the frame rail on severely lowered cars.

The main advantage of all this is a greater range of adjustability as we progress through different levels of power and grip. We still have enough adjustment to better dial in the car for the characteristics and driving purposes we have in mind.

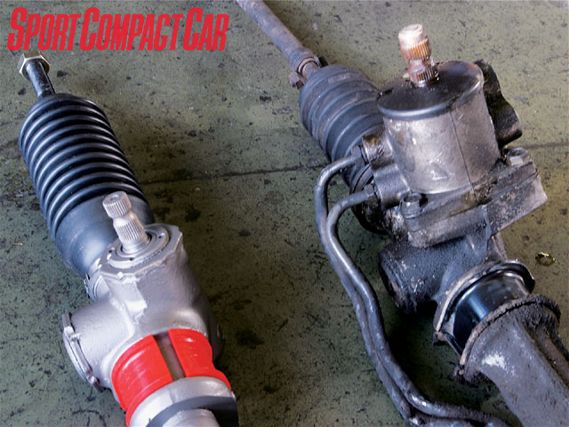

| The main difficulty in the manual steering conversion is making the steering yoke fit the new manual steering spline (left), which is smaller and sits lower.

| The main difficulty in the manual steering conversion is making the steering yoke fit the new manual steering spline (left), which is smaller and sits lower.

Power Steering Is For Little Girls

That's really not true. If anything, it's the other way around, since there's a good reason why manual steering is all but extinct. Anyone who insists on manual steering over power is still living in the Dark Ages. Only mid-engine sports and race cars still use manual steering, as there's little weight sitting on the front axles and it requires less hardware and space. We just didn't have an option-Project Corolla came equipped with power steering, but all the hardware was cannibalized long ago. All that was left was a sloppy power rack with fluid gushing everywhere. Bang for buck and weight, it was cheaper to go with a manual steering conversion, although there are drawbacks on track and in everyday use.

The swap to manual steering is a double-edged sword. It offers more steering feedback, giving a driver immediate information on how the front tires are loaded, without the buffering benefits of power steering. But a manual system will kick back through the steering column just as immediately and violently. In most cases, a lack of power-assisted steering also means that manual cars have a higher steering ratio and thus slower steering, making steering effort easier for the driver.

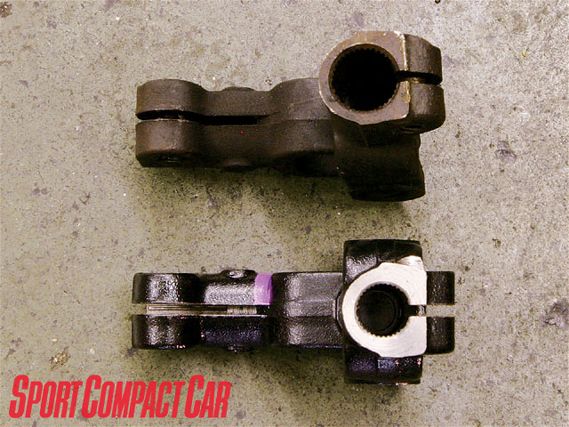

| The power steering yoke (top) is the same length as the manual yoke, but uses a larger-diameter female spline on the pinion end.

| The power steering yoke (top) is the same length as the manual yoke, but uses a larger-diameter female spline on the pinion end.

We didn't want to do the standard conversion and end up with sloppy econobox steering. So we opted to update our manual rack with a Quaife Quick Steering Ratio (QSR) rack-and-pinion kit made specifically for left-hand-drive AE86 Corollas. The kit replaces the internals of the Corolla's stock manual rack with a lower steering ratio, from 3.5 turns lock-to-lock down to 2.5. This is done by changing the diameter of the pinion and modifying the teeth on both parts.

However, the conversion isn't simply a matter of bolting in a new manual rack-and-pinion. Most parts are too costly to buy new and almost impossible to pillage from junkyards.

| With the steering column removed, you can see the male portion of the spline that inserts into the steering yoke. The power steering version (bottom) is much shorter and doesn't offer enough extension for the interference fit into the collapsible steering column to reach the manual yoke. This is the same size spline as the pinion side of the manual rack.

| With the steering column removed, you can see the male portion of the spline that inserts into the steering yoke. The power steering version (bottom) is much shorter and doesn't offer enough extension for the interference fit into the collapsible steering column to reach the manual yoke. This is the same size spline as the pinion side of the manual rack.

On the AE86, there are several differences that need to be addressed. The manual rack itself is somewhat rare in the US, as most Corollas came here with power steering. And the only other vehicle to share the same part was the first-generation MR2. We were able to locate one through Df Power Rebuilding in Buena Park, California, which specializes in rebuilding steering racks and CV joints. Diego Figueroa at Df Power was able to locate and rebuild a manual rack with the Quaife QSR components within a couple of days. That was the easy part.

Finding the rest of the bits and pieces was the hard part. We took Project Corolla down to Diamond Bar Auto Care to help us deal with dropping the front subframe, pulling the steering column and the modifications needed to make a manual steering car. Power rack housings have a larger diameter and use different mounting brackets and bushings on the passenger side, so it can't just bolt in.

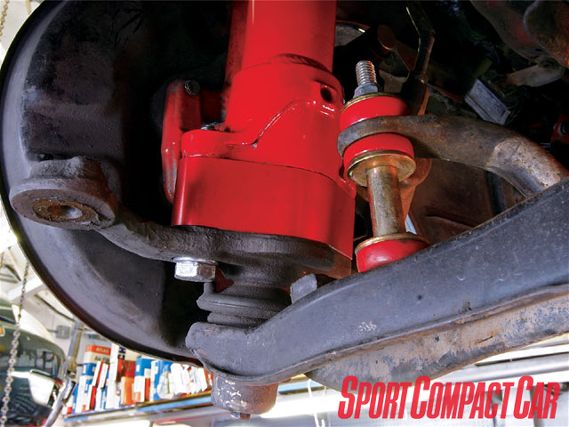

| The final difference between the power and manual steering hardware is the steering knuckle. Manual steering cars use a longer arm where the tie rod attaches. We kept the original power steering knuckles to maintain a better steering geometry, which also quickens the QSR's steering ratio.

| The final difference between the power and manual steering hardware is the steering knuckle. Manual steering cars use a longer arm where the tie rod attaches. We kept the original power steering knuckles to maintain a better steering geometry, which also quickens the QSR's steering ratio.

We replaced the driver-side bushing with a polyurethane unit from Prothane, while the passenger- (right-hand) side bushing was replaced with a CNC-machined Derlin bushing from Techno Toy Tuning (T3), made specifically for a power-to-manual steering conversion, since Toyota has discontinued the bracket and bushing parts.

The T3 bushing instructions require a bead of weld to be laid down along the rack housing to keep the bushing from sliding around on the rack, but we just drilled some holes and inserted pins into each half of the bushing to keep it in place. Our concern for the difference in stiffness of the two materials wasn't noticeable in steering feel, since the stiffer Derlin bushing was so much thicker and had more material to deflect.

| A Momo Mod 07 350mm steering wheel replaced the stock bus-sized tiller. It's also a lot sturdier than the flimsy old piece.

| A Momo Mod 07 350mm steering wheel replaced the stock bus-sized tiller. It's also a lot sturdier than the flimsy old piece.

Manual steering cars also use a smaller-diameter spline on the end of the pinion gear. This is by far the biggest issue with the manual swap-locating steering yokes or U-joints with the right sized female splines on both sides and extending the steering column to reach the new rack takes endless scouring of junkyards and forums. Two parts are needed, the actual yoke with the same smaller-diameter spline on both the pinion and column side, and the longer version of the male spline, stuffed into the steering column with an interference fit. The longer male steering column spline is necessary as the pinion box on the power rack is significantly taller.

There are three ways to get these parts, get lucky and find the pieces (or entire steering column) from an AE86 or older manual-steering Corolla in a junkyard, from forums (along with the matching steering column spline. Gimp up a long yoke by taking two much more common power steering yokes, hack off the end of the small spline on one and weld it to the end of the big spline of the other), or take it like a man, bending over at the dealer and buying the parts. We went for option three. Welding together two cast pieces in a critical component didn't seem like the smartest idea-and we strongly advise against it. At the time of writing, Toyota only showed seven yokes left in America.

The last difference is in the steering knuckles at the bottom of the front struts. Manual-steering cars have a longer arm on the steering knuckle that the outer rod end attaches to. The trade-off is (again) slower steering for less work. We stuck with the shorter power steering knuckles that came with the car. Not so much because we wanted faster steering, but because the longer manual steering knuckles force the tie rods further back at an increased angle, which contributes to an on-center vagueness and minor bumpsteer issues. Our Frankenstein steering is down to almost two turns lock-to-lock and kicks back from surface changes hard enough to sprain the wrists of the unwary. Outrageous for an everyday street car, Project Corolla turns and rolls like a go-kart.

To make it even harder on ourselves, we dumped the flimsy stock two-spoke plastic deathtrap steering wheel for a much more solid 350mm diameter Momo Mod 07 dished item. It might seem vain, but the inch-and-a-half reduction in diameter and the more solid construction adds a lot to steering feel as well as placing the wheel in a better position. The smaller wheel does, however, require quicker hands and more effort, and will also kick back quicker.

Another side effect of the new steering hardware is the added steering angle, which now rubs the tires against the inside fender along the frame rail at full lock. We resorted to a temporary street solution by fitting a set of 14x7 Toyota Celica Supra Mk2 wheels. They're half an inch wider than the stock Corolla pizza-cutters, have slightly less offset, which pushes the wheel out a little more to stop the rubbing, and weigh almost as much as steel wheels.

| Project Toyota Corolla AE86

| Project Toyota Corolla AE86

Shop Corner: Diamond Bar Auto Care

While the shop looks like any other gas station repair shop from the outside, the array of Corolla, Starlets, JDM-swapped Soarers, RX-7s and 240SXs in the parking lot is just a hint of owner Ray Gonzaga's vast experience with eclectic Japanese rear-wheel drive. His prized 1983 400hp turbo Starlet race car is also an indication of how serious and crazy he is. But this is a good place to go for Corolla service and tuning. Gonzaga and his team will do anything from an oil change to the rare JDM engine change. He has over 20 years of experience racing and tuning Toyotas.

Diamond Bar Auto Care

2875 S. Diamond Bar Blvd.

Diamond Bar, CA 91765

(909) 861-3307