| Project Focus Part One: The Intro

| Project Focus Part One: The Intro

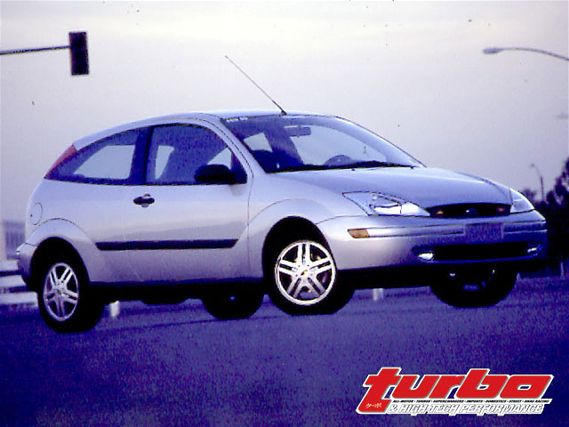

With our 1.3-liter Euro-spec Focus a distant memory we are now turning our attention to our U.S. 2.0-liter model and starting Project Focus from square one. Our goal is to run the gamut of mods from basic bolt-ons to boost with the intention of having a swift and stylish street/strip car at project's end. Since the Focus is brand-spanking- new we ran into the common problem of no new parts for the new ride. We were forced into submission and decided to use a wide variety of aftermarket parts that will have to be custom-tailored to our Focus.

In factory trim, the Zetec engine displaces 2.0 liters and pumps out 130 horsepower at 5300 rpm and 135 lbs-ft of torque at 4500 rpm. In order to distinguish horsepower differences in our upgrades we needed a reliable baseline so we scheduled dyno time straight away.

We hit the Dynojet dynamometer at AEBS in San Diego, Calif. to see what the Focus could produce at the wheels. In OEM trim the Focus was able to lay down 110 horsepower. Although these horses were in clear need of a whip or a shot of steroids it should be noted that the Zetec produced some righteous torque numbers. Right from the get go the Focus produced between 120 to 110 lbs-ft of torque all the way to 5500 rpm. Considering our Focus is going to be performance-prepped this torque curve is promising and considering our car weighs in at 2564 pounds without driver, we expect the Focus to be a very competitive street car with all the comforts of a limousine minus the fully-stocked bar.

So what can a 2564-pound Focus that pumps out 110 to the wheels run in the quarter? Being curious enthusiasts we decided to run the vehicle at Carlsbad Raceway. Of course our first few passes were thrown out due to the fact we needed to get use to the car's personality. But after some wheel time we got in the groove and the Ford averaged 16.87 at 81.77 mph.

As we stated earlier, most of the parts added to make horsepower needed some fabrication. Since we decided to start out with the basic upgrades for our Project Focus our only modifications were to the factory air intake and exhaust system.

Our first mod would require removing the factory air box to outfit an open element style air filter. The Focus mass air meter utilizes a 3.5-inch outside diameter which required us to locate a filter with an equivalent inside diameter. Pann Auto in San Diego, California happened to have a S&B open-element model with a three and a half-inch inside diameter handy for testing. Our only major modification was the removal of the factory rubber intake pipe to be replaced by a sturdier 3-inch mandrel-bent piece. The 3-inch intake was a challenge to install due to the sharp bend the intake pipe needed for proper hood clearance. Since the OEM intake manifold incorporates a plenum that positions the throttle body straight up this makes fabricating an intake pipe much harder. With the help of Pann Auto's technician Tim Brown we were able to construct a pipe that delivered the goods.

The exhaust system was much trickier to fabricate than the air filter system. Due to the factory muffler being about the size of a small city phone book, it was difficult to locate a muffler in a similar size. Our only option for now was to outfit a Tanabe Racing Medalion N1-style muffler with the inlet set towards the center of the car. This required routing the 2.25-inch piping under the factory suspension rather than the factory route which happened to be over the rear suspension. Removing the factory 1.75-inch exhaust system also required cutting since it was a one-piece system it was impossible to pull the exhaust out in one piece without dropping the whole rear suspension.

The new exhaust we prepared is 2.25 inches in size and utilizes most of the factory hangers. Once we were done spot welding the exhaust system together, Carl Batac from Rells Performance Motorsports buttoned it up by TIG welding the one-off, one-piece 16 AWG exhaust system. Only one of the hangers was relocated to suit the needs of the rerouted piping. The Racing Medalion muffler runs a 2.25-inch inlet with a 2.5-inch outlet. One handy feature on the muffler is its removable baffle. This option comes in handy for daily driven vehicles that do not want the annoying exhaust hum but want the extra power come track time.

Second RoundBack at AEBS dyno the Focus was strapped down equipped with the exhaust system and an open-element air filter system. The horsepower figures increased to 114.3 with 123.7 lbs-ft of torque at peak. Most of the ponies were realized in the high rpm area of 4500 to 6500 rpm.

Our last runs on the dyno were to see if we could gain any power by going to a thinner race oil. Our oil of choice was Jet Set Life Technologies, Oil Extreme. Oil Extreme claims to be a, "Better than Synthetic" petroleum-based oil. We added four quarts of SAE 5W-30 and the four-ounce Oil Extreme concentrate to the mix hoping for a little extra ponies. Once the oil was broken in we strapped the Focus to the dyno to gain 1.1 horsepower and 9 lbs-ft of torque maxing out the Zetec at 115.4 horsepower and 124.3 lbs-ft of torque.

Once we were finished on the dyno it was back to Carlsbad Raceway to see what the extra horsepower translated to in e.t.s. One key factor to consider is the extra fuel we were carrying. For our first session at Carlsbad we had a just over three gallons in the tank (a little over 18 pounds), this particular day we were three gallons short of a full tank. This means we had 10 gallons (62 pounds) of fuel. Although 44 pounds doesn't seem like much, it is enough to impact the performance of our inline 2.0-liter. After a few practice runs the consistency of the vehicle and driver were set. The Focus locked in an average of 16.46 at 82.36 mph. Considering that the Focus was equipped with just an aftermarket exhaust system and air filter, these results are quite good.

Before project Focus undergoes forced-induction therapy we are considering how the vehicle will handle a light dose of nitrous. When the Zetec four is mated with a reliable turbo system it will be up to Brian Axup and the crew from Esslinger to fondle the internals of the inline 2.0-liter Zetec engine to take the abuse of extreme intake pressure. In upcoming installments of Project Focus we will concentrate on aesthetics like wheels and tires (maybe a body kit) as well as traction via Competition Engineering whose suspension components will help transfer power to the ground more efficiently.