Everyone knows the feeling of never having enough power. But it's a far better feeling than the moment when you realize there isn't enough braking. Unfortunately, that's the case for our time attack project Z. With more than 500 whp and stock, base-package brakes, the car can barely keep itself in check while bleeding off highway speed, little less sustain a hot lap on track.

|

We rounded up and compared front brake calipers for the 350Z from top to bottom: cast-iron, single-piston, floating caliper from the base package Z (10.38 lbs); Brembo cast-aluminum, two-piece, four-piston, fixed calipers from the track package Z (7.07 lbs); StopTech six-piston, forged-aluminum Trophy Sport caliper (7.92 lbs); and an OEM squeeze forged-aluminum monobloc caliper from a Porsche.

|

We rounded up and compared front brake calipers for the 350Z from top to bottom: cast-iron, single-piston, floating caliper from the base package Z (10.38 lbs); Brembo cast-aluminum, two-piece, four-piston, fixed calipers from the track package Z (7.07 lbs); StopTech six-piston, forged-aluminum Trophy Sport caliper (7.92 lbs); and an OEM squeeze forged-aluminum monobloc caliper from a Porsche.

So we're now addressing the all critical brake factor in preparation for the Super Lap Battle. But there's a catch. We're not building a race car, and we don't want race brakes. The whole point of this project car is to build something that can perform under heavy track day conditions, but still be driven as daily transportation without the race car headaches. This means we needed a brake system that can consistently stop a very heavy full-interior car on the track without fading, provide reliable and quiet braking for everyday use at street temperatures and speeds, and not require constant service or rebuilding like a true race brake. StopTech's new Trophy Sport series of big brake kits was designed specifically to fit needs like ours.

The Trophy Sport brakes are a street-friendly version of StopTech's recently introduced top-of-the-line, track-only Trophy series brakes. The Trophy Sport uses the same lightweight, forged, two-piece, staggered-piston calipers that are reinforced with the same StopTech patented caliper bridge brace and clocked for minimal knockback as the Trophy brakes. However, the Trophy Sport includes amenities like piston dust seals, hand brake provisions and a version of the true full-floating, two-piece slotted differential curved vane rotor featuring sufficiently constrained floating freedom for street use.

If you have no idea what was just said, however badly it was written, it's OK. By the end of this article, you should know enough about basic brakes to blab away like a proper brake geek. To better understand why we picked StopTech's Trophy Sport Brake System and help you better pick the right brakes for your needs and budget, we'll have to go through some brake system fundamentals.

|

Project Nissan 350z - Brake Guru 101

|

Project Nissan 350z - Brake Guru 101

Obviously, the role of brakes is to slow down the car. More appropriately, a braking system takes away the kinetic energy of your moving car by converting it into heat energy through friction. The ability to maintain friction and dissipate heat is what brakes are all about. Brakes can be broken down into three basic components: the rotating assembly like a rotor or drum; the fixed portion with the calipers, and pads/shoes; and the controls that involve the hydraulics, master cylinder, biasing circuit and traction controls and ABS. We'll ignore the control components because few people modify this and it's a big can of worms except to say that the size of the brakes has to be designed to work with the master cylinder size, the ABS and the active handling control system.

Floating Calipers Outside of the very antiquated drum brake design, most brake calipers can be broken into two categories: fixed or floating. A floating or sliding caliper is the more economic caliper with two pieces: the inboard portion that houses the piston and is rigidly bolted to the wheel upright, and the sliding component that rides on two slide pins and extends out around the rotor much like a C-clamp. Because of the weaker C-clamp shape and more compact size, these calipers are typically cast from iron, which is stiffer but much heavier than aluminum. Floaters typically have no more than two pistons on passenger-car applications just like on our base-package 350Z brakes. The pistons on one side of the caliper control the clamping force of both pads.

|

The Trophy caliper (top) doesn't feature the gray dust seals on our Trophy Sport calipers (bottom). Both calipers feature staggered pistons, where pistons slightly increase in size from left to right.

|

The Trophy caliper (top) doesn't feature the gray dust seals on our Trophy Sport calipers (bottom). Both calipers feature staggered pistons, where pistons slightly increase in size from left to right.

Sliding calipers are simple, cheap and easy to maintain, but are less efficient due to the frictional losses of the sliding pins and rotor drag on the pads. They are ideal for street cars because they take up much less space than fixed opposing piston calipers. It is worthwhile to note that top vehicles like BMW's M-series cars use floating calipers for reasons they feel are advantageous over fixed systems.

|

Starting from left to right, the 350Z base package front rotor (16.6 lbs), track package front rotor (20.2 lbs), aftermarket straight vane, cross-drilled rotor, and the StopTech 2-piece front rotor for the 350Z (18.03 lbs).

|

Starting from left to right, the 350Z base package front rotor (16.6 lbs), track package front rotor (20.2 lbs), aftermarket straight vane, cross-drilled rotor, and the StopTech 2-piece front rotor for the 350Z (18.03 lbs).

Fixed Calipers

Most aftermarket big brake systems, some high-end sports car's brakes and most race applications use a fixed caliper design. Fixed calipers are rigidly mounted to the hub and use opposing pistons on each side of the rotor to clamp down onto the pad. Oftentimes, higher-quality calipers with two or more pistons on each side use a staggered piston layout where the leading piston (in the direction of rotor rotation) is smaller than the pistons behind it. This decreases the force on the leading edge of the brake pad, creating more even pad wear.

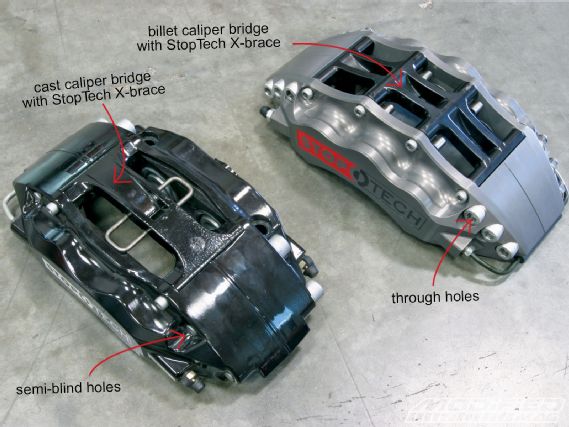

The only moving components of a fixed caliper are the pistons themselves which are positioned in each side of the caliper and pushing on each pad. Fixed calipers are typically made from cast, pressure-cast or forged aluminum, depending on the quality of the brakes. Because of this, more of the lower stiffness aluminum material is typically required when compared to steel. The trade-off is less weight but more space. The Track Package 350Z uses mass-produced, pressure cast-aluminum, four-piston calipers from Brembo just like EVOs and STis. These are less dense and have poorer grain structure than forgings like on higher-end aftermarket products. To help increase strength, StopTech also uses a patented X-brace across the caliper opening to further prevent the halves from spreading apart as the pistons squeeze against the pads and rotor.

|

The Trophy Sport rear rotor (left) features an aluminum hat with provisions for a drum-style parking brake compared to the race-only Trophy rotor (right). Since the hats are aluminum, drifting with the parking brake isn't recommended.

|

The Trophy Sport rear rotor (left) features an aluminum hat with provisions for a drum-style parking brake compared to the race-only Trophy rotor (right). Since the hats are aluminum, drifting with the parking brake isn't recommended.

There are also fixed calipers that are monobloc in design, meaning it's not made of two halves. In theory, the monobloc is a stiffer design, but due to cost limitations, monoblocs are typically pressure-cast instead of forged. This means it's not as rigid. In addition, a two-piece fixed caliper uses steel caliper bolts to hold the two halves together, which significantly increase its overall stiffness compared to just a pressure-cast monobloc. If price was no object, forged monoblocs with extremely expensive alloys can be stiffer and stronger, but even these types of parts have been banned in F1 to minimize costs.

Our StopTech Trophy Sport brakes use a two-piece caliper reinforced by the company's patented machined X-brace. The brace also includes vaned orifices to help remove hot air away from the rotor. In the case of the Trophy and Trophy Sport calipers, StopTech went the extra step to increase caliper stiffness by using through holes for the caliper bolts. This means the two caliper body halves are clamped together with bolts secured by a nut on the other side instead of a slightly weaker blind hole design, where the bolt threads into the aluminum body itself. Through the use of computer modeling and simulation, StopTech was also able to further reduce overall caliper weight by machining out extraneous material on the caliper body itself without any sacrifice to overall caliper stiffness. Our Trophy Sport calipers also feature newly developed high-temp, silicon-rubber dust seals (all OE street brakes use rubber seals) around each piston to prevent dirt from entering and gouging the piston bores. True race brakes like the Trophy brakes don't use these due to the extreme temperatures they are constantly exposed to and the fact that race brakes are rebuilt on a regular basis. As a final touch, both Trophy and Trophy Sport calipers use a harder Type 3 semi-transparent anodizing that is more chip- and fade-resistant under high heat.

|

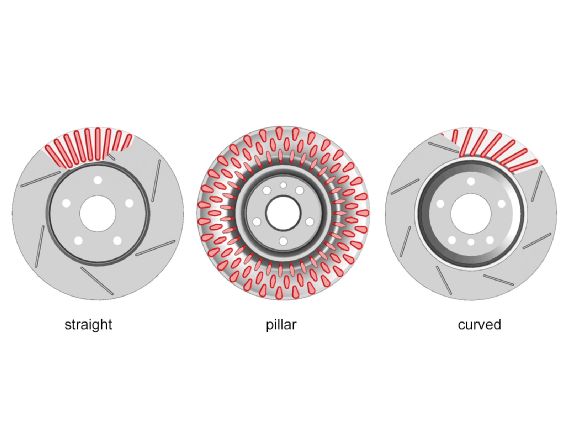

Most OEM rotors use a non-directional straight or pillar vane design (left and center); high-performance OEM and aftermarket rotors (right) use a directional curved vane rotor for better cooling abilities. Note that the slots are machined in the opposite direction of the vanes for better strength.

|

Most OEM rotors use a non-directional straight or pillar vane design (left and center); high-performance OEM and aftermarket rotors (right) use a directional curved vane rotor for better cooling abilities. Note that the slots are machined in the opposite direction of the vanes for better strength.

Rotors

Rotors are the spinning part of the brakes that the calipers and brake pads clamp onto. In addition to providing a friction surface, the rotor's main role is to pump away heat generated through braking because it experiences the highest temperatures. Most rotors are sand-cast from gray iron of various qualities and have an air gap between the two rotor faces. The air gap (commonly referred to as a vented rotor) allows air to move through the rotor and pull away heat. Solid rotors also exist, typically on the rear brakes of non-performance platforms. Several designs exist for the vents, but most can be broken down to directional or non-directional categories. As the name suggests, non-directional (aka straight vane) rotors can rotate in either direction and still provide venting, although not as effectively. Stock factory brakes and lower-end replacement rotors use this design because the same part can be used on both sides of the car. A take-off of the straight vane design is the pillar vane design that is better at maintaining a smooth, consistent friction surface.

|

The StopTech two-piece rotor uses a differential curved vane rotor design. The offset long and short vanes increase the rotor's ability to pull air from the inside to the outside of the rotor. The mounting hole for the aluminum hat is slotted to allow radial growth of the rotor as it heats up and expands.

|

The StopTech two-piece rotor uses a differential curved vane rotor design. The offset long and short vanes increase the rotor's ability to pull air from the inside to the outside of the rotor. The mounting hole for the aluminum hat is slotted to allow radial growth of the rotor as it heats up and expands.

Directional or curved vane rotors only cool effectively when rotating in the right direction but are far more efficient at moving cooling air through the rotor. Most high-performance applications and race rotors (with the exception of carbon/carbon rotors) use curved vane rotors. A directional vane rotor upgrade on cars like the EVO, Z or STi are a simple but hugely effective choice. Our StopTech rotors use a patented variation of the curved vane design called Aerorotor with alternating differential curved vane lengths to further increase cooling effectiveness. To maintain rotor strength, slots and drills in curved vane rotors are typically machined in the opposite sweeping direction than the vanes so that a slot doesn't occur directly on top of a vane or a hole drilled through it.

Fixed Or Floating Rotors

A further step in upgrading rotors is to use a two-piece or floating design. (Don't be fooled by single-piece rotors with painted black hubs and fake rotor bolts.) Real floating rotors have reduced weight, rotational inertia, heat transfer to the wheel bearing, rotor deformation and knockback effects. The trade-off is obviously a much higher price, which is why these rotors only show up on stock vehicles like Ferraris, GT-Rs and the EVO X MR.

|

Project Nissan 350z - Brake Guru 101

|

Project Nissan 350z - Brake Guru 101

By using an aluminum hat that's semi-solidly attached to the rotor, a true floating rotor allows the rotor to expand and contract radially as heat is increased. Slotted mounting holes machined in the rotor friction disc allow the rotor to grow without stretching and deforming the hat. The two pieces are attached using drive pins, Belville washers made from Inconel and bolts that allow the rotor to expand and contract concentrically through heat cycles, but stay in-plane with the hub to reduce noise. The total amount of float is controlled by a strictly held tolerance on the drive pin length and the Belville washer design. Two-piece rotors when used in racing are designed to have axial float, which allows the rotor to slightly wobble as if you have a bad wheel bearing. Under race conditions, axial float allows the rotor to better align to the caliper and pads as it spins, which helps reduce knockback. Too much axial float is bad on a street car because it makes all kinds of noise. To keep the street/track balance, StopTech assembles the Trophy Sport rotors to have less float than the race-spec rotors.

Knock Back

You might be wondering what this term "knockback" we keep referring to might be. Racers often talk about brake knockback, but every car experiences it to some degree. Knockback comes during cornering as uprights and wheel bearings bend and deform slightly under the load coming from the wheel and tires. Race cars with sticky tires and downforce experience this much more. As these components temporarily deform, the brake rotor and caliper are forced to bend with it, bringing rotor and pads out of alignment as if the rotor was warped. In extreme cases, the rotor will actually push the brake pads and pistons apart as it wobbles through the caliper. When you step on the brakes after cornering, the pedal goes to the ground because all the effort went into pushing the pads back into place and not stopping the car.

|

Project Nissan 350z - Brake Guru 101

|

Project Nissan 350z - Brake Guru 101

Unfortunately, larger rotors (because of the larger radius) and stickier tires will increase the effects of knockback. The notoriously flimsy wheel bearings on the 350Z don't help either. To compensate for this, StopTech designed the mounting brackets for Trophy and Trophy Sport brakes to clock the caliper to a 3 o'clock position (instead of the stock 2 o'clock position). The geometry and direction of hub deflection means the rotor wobbles least at these positions. This can reduce how far back the brake pads are knocked back. Two-piece rotors with more axial float also help.

Now that we can stop on the street and track, we now need a new suspension that's both competent on the track and tolerable on the street like our brakes.