Welding 101: Part III

Throughout these past few months, we've put together a beginner's guide that will help you explore the most basic fabrication fundamental - MIG welding. For Part III of the story, we decided to explore a little deeper, with some of the basics of MIG-welding aluminum. Aluminum is a little tougher to MIG-weld than steel, so once you master this, you'll be able to weld almost any ferrous metal.

| 0503mt Weld00 Z

Miller Electric makes an optional spool gun that's easily added to any of Miller's compatible welders. In this article, we used the SpoolMate 3035 in conjunction with a Millermatic 210 welder. This setup can weld aluminum as thick as 3/8 inch in a single pass. The system and setup is easy, and with Miller's Gun-On-Demand system, you can hook up two gas bottles and both guns and simply use whichever the job requires. To weld aluminum, you'll need to install the spool gun, feed the aluminum wire into it, and hook up a bottle filled with 100 percent argon. Once everything is properly connected, you can get right to work practicing and learning how to weld aluminum. Keep in mind the tips on the following pages, and you'll be on your way to building your own fuel cells in no time.

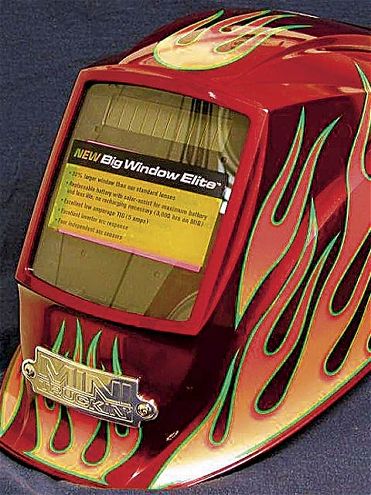

We teamed up with Miller Electric to give away a welding helmet with a contest we introduced in Part I. Well, since we can't leave anything well enough alone, we also decided to customize the helmet with a one-off billet badge from KAIK Products (www.kaikproducts.com). Pictured here is the customized helmet we'll be giving away and an up-close shot of the one-off badge. To enter, you'll need to use the Welding 101 series to practice your welds and log onto the Web site for the specifics. We printed the wrong Web site in the previous two articles. The actual Web site for the contest is www.millerwelds.com/primedia. We've extended the contest for two months to give everyone a chance to enter. For all the details of the contest and to submit an entry, check out the Web site listed above.

| 0503mt Weld00 Z

Miller Electric makes an optional spool gun that's easily added to any of Miller's compatible welders. In this article, we used the SpoolMate 3035 in conjunction with a Millermatic 210 welder. This setup can weld aluminum as thick as 3/8 inch in a single pass. The system and setup is easy, and with Miller's Gun-On-Demand system, you can hook up two gas bottles and both guns and simply use whichever the job requires. To weld aluminum, you'll need to install the spool gun, feed the aluminum wire into it, and hook up a bottle filled with 100 percent argon. Once everything is properly connected, you can get right to work practicing and learning how to weld aluminum. Keep in mind the tips on the following pages, and you'll be on your way to building your own fuel cells in no time.

| 0503mt Weld00 Z

Miller Electric makes an optional spool gun that's easily added to any of Miller's compatible welders. In this article, we used the SpoolMate 3035 in conjunction with a Millermatic 210 welder. This setup can weld aluminum as thick as 3/8 inch in a single pass. The system and setup is easy, and with Miller's Gun-On-Demand system, you can hook up two gas bottles and both guns and simply use whichever the job requires. To weld aluminum, you'll need to install the spool gun, feed the aluminum wire into it, and hook up a bottle filled with 100 percent argon. Once everything is properly connected, you can get right to work practicing and learning how to weld aluminum. Keep in mind the tips on the following pages, and you'll be on your way to building your own fuel cells in no time.